Hidden type reinforcing node of side span node of wood structure traditional architecture and preparation method of hidden type reinforcing node

A wooden structure and concealed technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of mortise and tenon joint pullout resistance and low joint stiffness, and achieve simple structure, improved pullout resistance, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

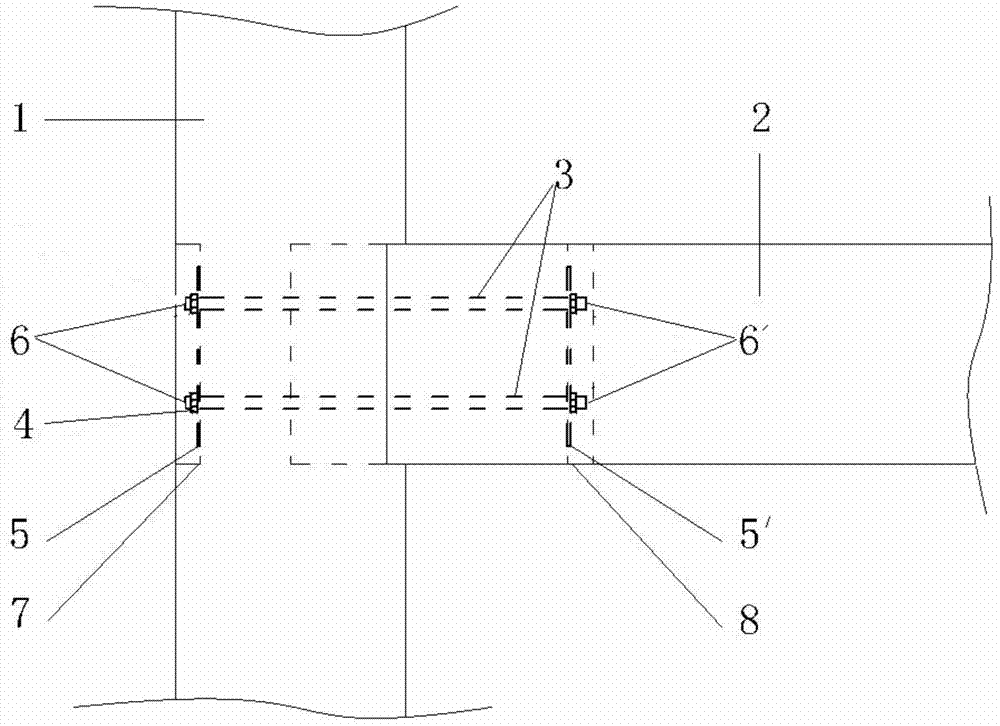

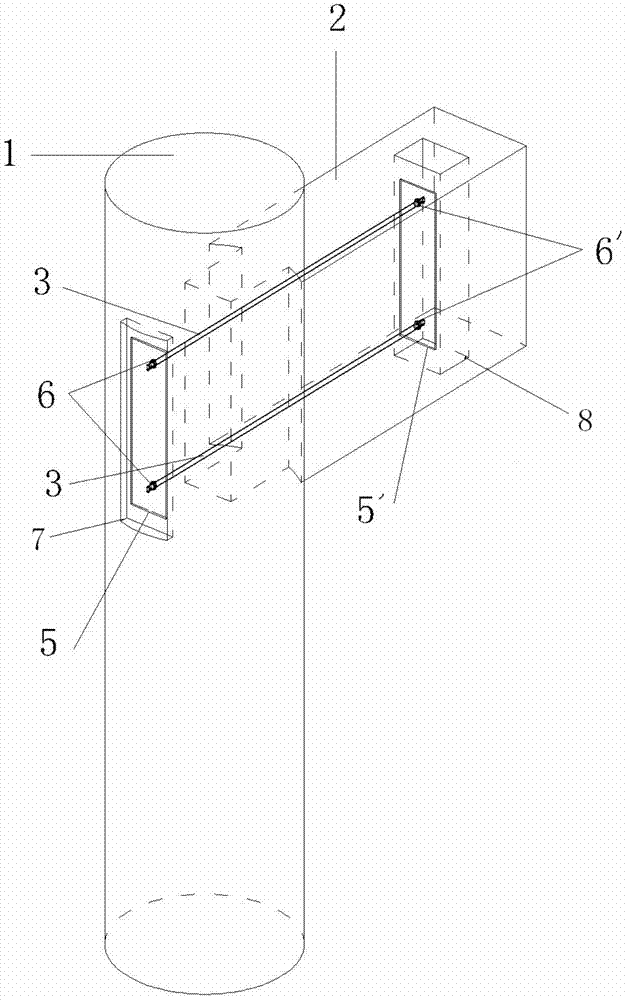

[0038] see figure 1 , figure 2 , The node reinforcement structure of the present invention includes a log column 1, a log beam 2, and a connecting tie rod 3, a nut 4, a stiffening plate and a groove on the concealed reinforcement.

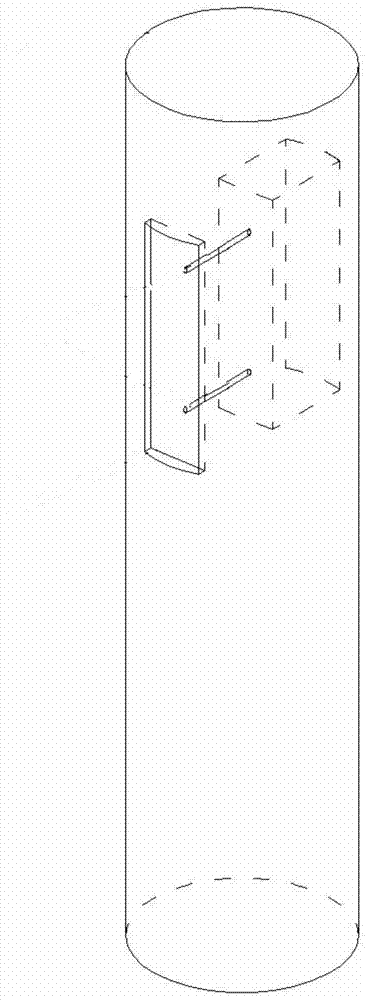

[0039] see image 3 , Figure 4 , the two ends of the connecting rod 1 are provided with threaded buckles for fixing the nut 4, and the screw rod can also be directly used as the connecting rod 1. During reinforcement, the connecting rod passes through the reserved holes on the stiffening plates 5 and 5 ', and is fixed with the fixing nut 4.

[0040] see Figure 5 , Figure 6 , at the end of the connecting long tie rod outside the log column body and the log beam beam body, pick out the concealed groove 7 and the through hole groove 8 respectively to facilitate the installation of the stiffeners 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com