Novel revolving cup bearing

A new type of bearing technology, used in textiles and papermaking, continuous winding spinning machines, open-end spinning machines, etc., can solve the problems of reduced service life, poor bearing lubrication effect, high noise, etc., to reduce production. cost, reduced internal wear and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

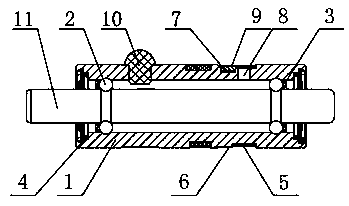

[0014] Such as Figure 1 to Figure 2 As shown, the present invention includes an outer ring 1, the inner two ends of the outer ring 1 are equipped with a cage 3, the cage 3 is matched with the ball 2, and the ball 2 is located in the annular groove on the mandrel 11; There are first oil filling holes 12 and steps near the cage 3 respectively. The first oil filling holes 12 are closed by the filling plug head 10, which can prevent the lubricating oil inside the bearing from leaking and foreign impurities from entering the inside of the bearing. The steps are formed by the first step 5 and the second step 6, the first step 5 has a second oil filling hole 8, preferably, the diameter of the outer circle of the first step 5 is Φ14~Φ22mm, and the width is 1~20mm, the outer circle of the second step 6 The diameter is Φ18~Φ22mm, the width is 1~10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com