Feed system for textile processing machine

A supply system, processing machine technology, applied in textiles and papermaking, needle punching machines, non-woven fabrics, etc., can solve problems such as loss, product characteristics are no longer fully realized, and achieve the effect of reliable transportation and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

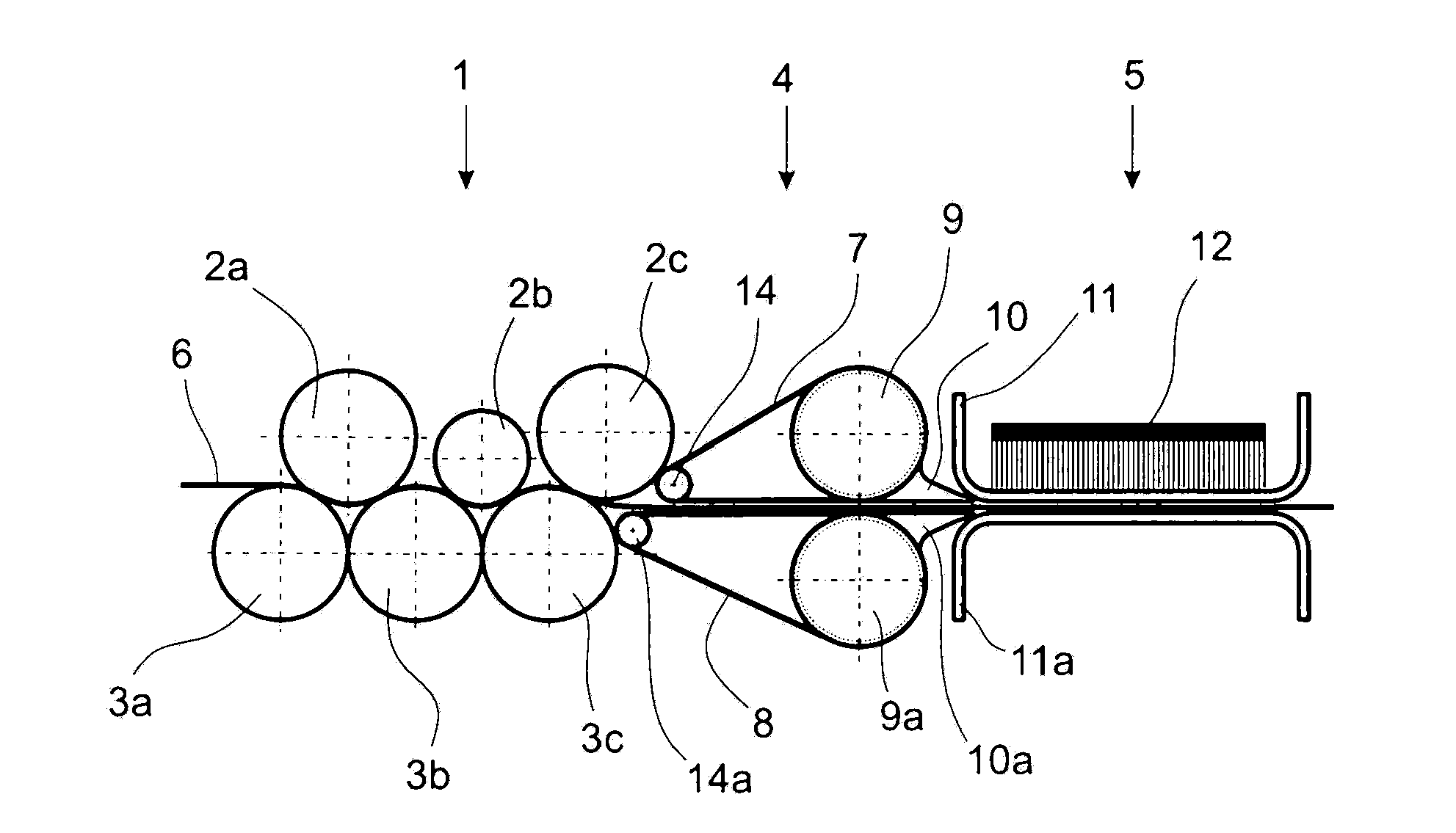

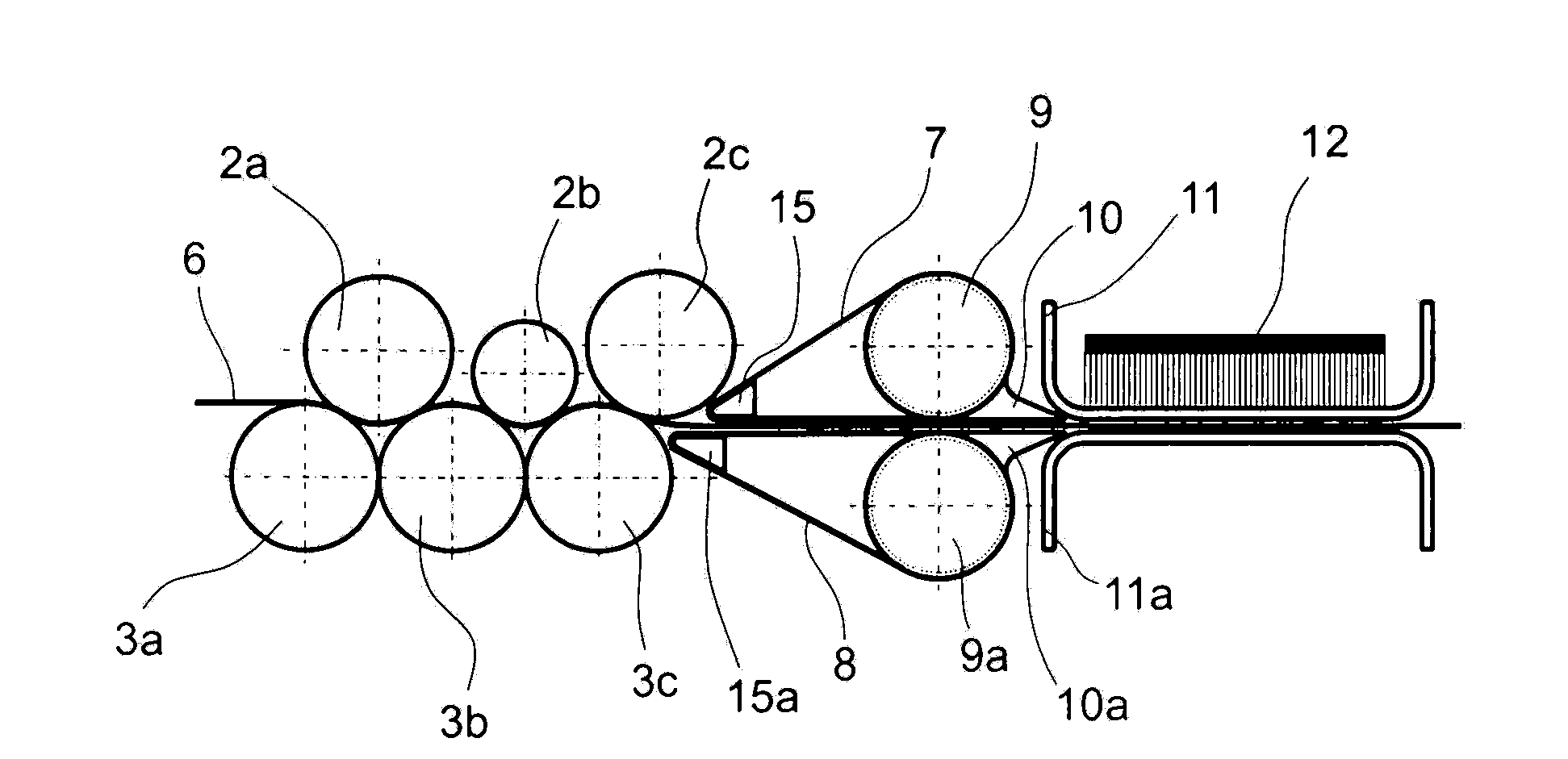

[0032] figure 1 The supply system 4 of a needle loom 5 is shown, symbolically only its reinforcement region 12 in the form of a needle plate. Before the needling machine 5, the rollers 2a-2c and 3a-3c form a drafting path 1 with which the fiber orientation of the nonwoven web 6 can be adjusted, for example after a crosslapper not shown. By means of the peripheral speed of the rollers 2a-3c, the nonwoven fabric web 6 can be stretched or compressed. A supply system 4 according to the invention is arranged between the drafting lane 1 and the reinforcement zone 12 , in which supply system the nonwoven web 6 is guided between the underlying conveyor belt 8 and a further conveyor device. The further conveying device can in principle be embodied as a further belt, in this example as a cover belt 7 , or as at least one roller or roller.

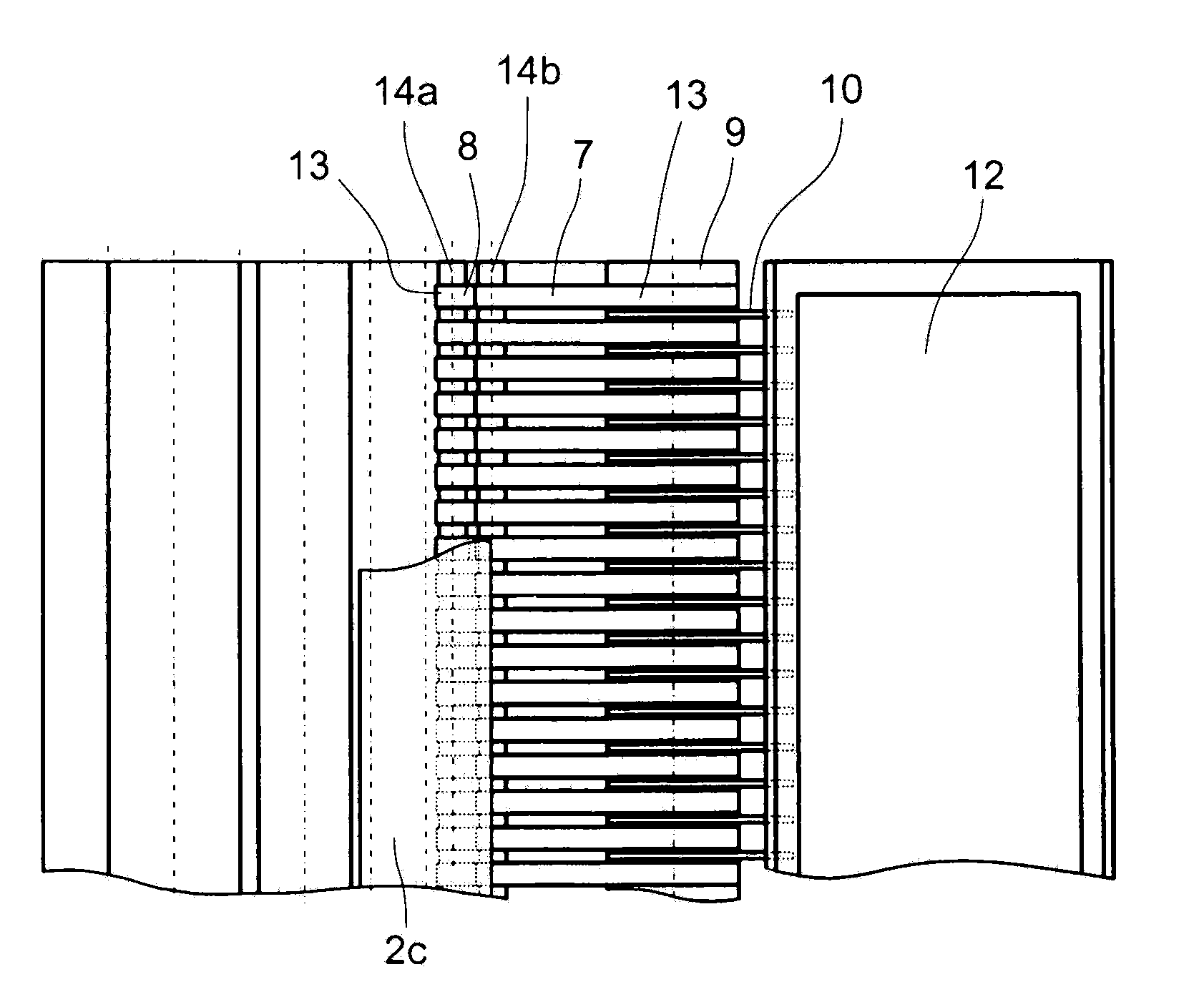

[0033] exist figure 2 As can be seen in the figure, in the supply system 4 of the needling machine 5 thread guides 10 are used which are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com