Rotary electroplating machine and automatic discharger thereof

A technology of automatic unloading device and electroplating machine, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of time-consuming and laborious, material leakage, material jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

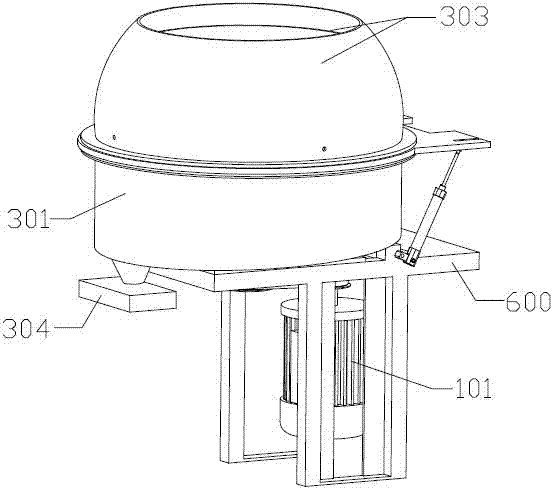

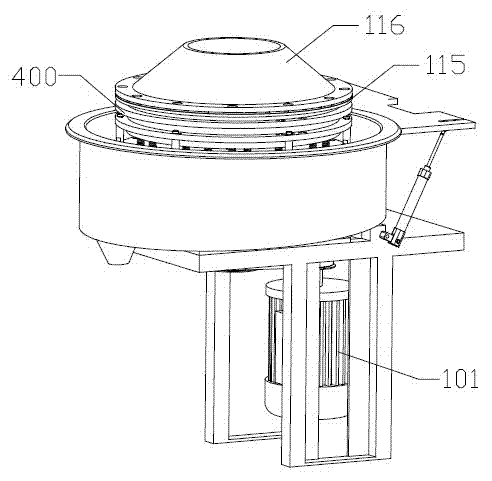

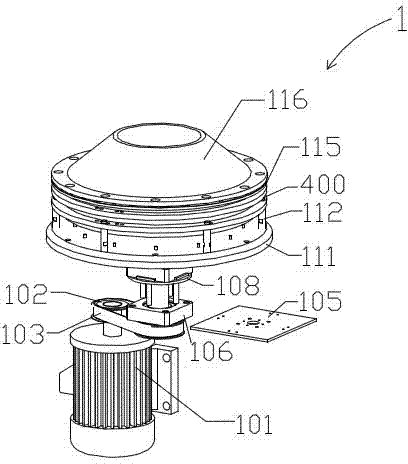

[0038] like figure 1 and figure 2 As shown, the invention discloses a rotary electroplating machine, which is used for electroplating and unloading of chip components. like figure 1 , image 3 , Figure 8 and Figure 11 As shown, the rotary electroplating machine of the preferred embodiment of the present invention includes a cathode ring rotation mechanism 1, an automatic separation mechanism 2, a discharge mechanism 3, a cathode ring 400, a rubber disc 500, a frame 600, and an anode titanium cylinder (not shown in the figure) ) and a rectifier (not shown). During the electroplating production of the rotary electroplating machine, the anode titanium cylinder (not shown in the figure) is lowered into the cathode ring 400, and the plating solution is continuously replenished in the cathode ring 400, and the cathode ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com