Guide-plate microbial electrolysis cell embedded with multi-electrode system and use method thereof

A microbial electrolysis cell and deflector technology, which is applied in the electrolysis process, electrolysis components, biological sludge treatment and other directions, can solve the problems of difficulty in large-scale development, small size of the MEC system, and low hydrogen and methane content, and achieve stable and continuous Stream operation, get rid of the constraints of small size, reduce the effect of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

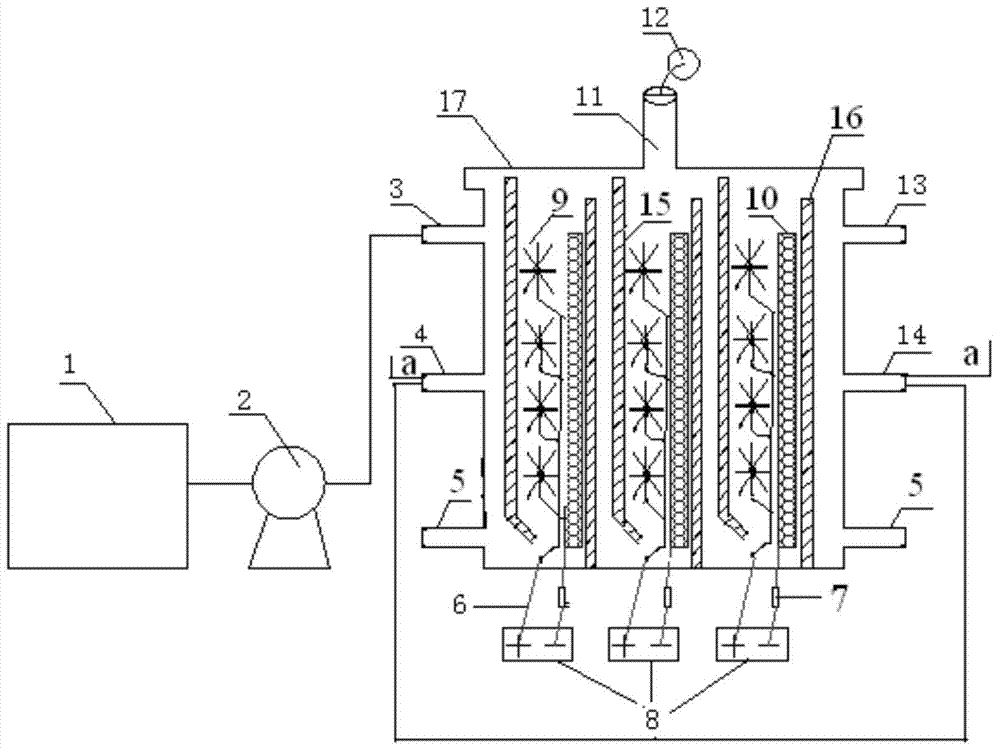

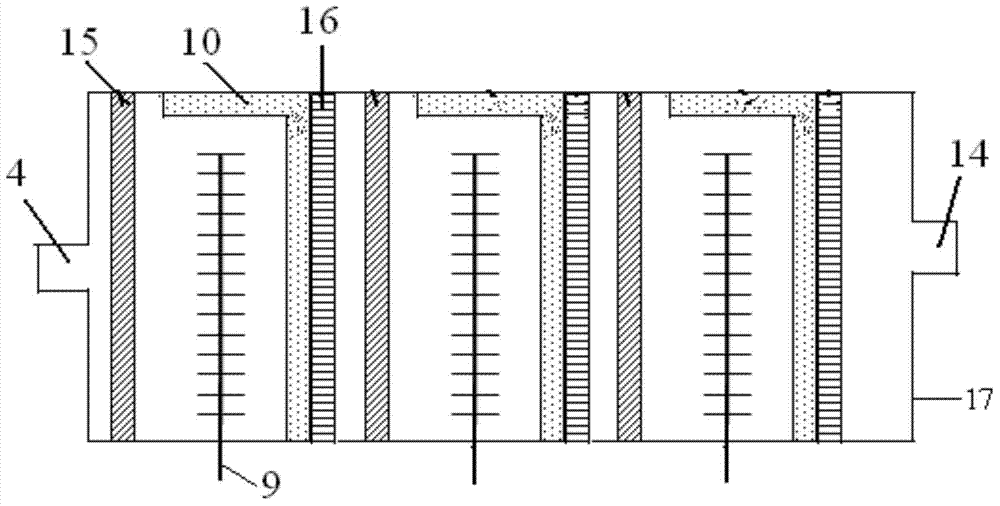

[0017] Specific implementation mode one: combine figure 1 and figure 2 , a deflector type microbial electrolytic cell with a built-in multi-electrode system in the present embodiment, which includes a water tank 1, a water pump 2, a resistor 7, a power supply 8, an anode carbon fiber brush 9, a cathode steel mesh 10 and a baffle box 17; The baffle box body 17 is provided with a water inlet 3, a water outlet 13, a backflow water outlet 14, a backflow water inlet 4 and two water discharge ports 5, the water outlet of the water tank 1 is connected with the water inlet of the water pump 2, The water outlet of water pump 2 links to each other with the water inlet 3 of baffle box body 17, and the backflow outlet 14 of baffle box body 17 is connected with the backflow water inlet 4 of baffle box body 17, and in the baffle box body Each group of downflow plates 15 and upflow plates 16 forms a compartment, and there are 3 to 6 compartments in the baffle box, each compartment has a vo...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the cathode steel mesh 10 is a stainless steel mesh of 60 mesh SS306; the preparation method of the cathode steel mesh 10 is: PTFE is used as a binding agent and activated carbon The activated carbon powder is mixed to make the activated carbon powder into a whole, and then the activated carbon is pressed on the stainless steel mesh by a roller press to obtain the cathode steel mesh 10. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the baffle box 17 is plexiglass. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com