Rubber composition

A technology of rubber composition and natural rubber, which is applied in the chemical industry to achieve the effects of good processing performance, high strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

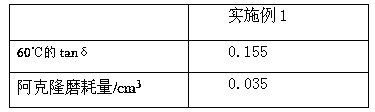

Examples

Embodiment 1

[0024] In the present embodiment, the rubber composition comprises the following components in parts by weight:

[0025] Guayule: 80 SBR 60

[0026] Polyvinylsiloxane 10 Polyphenylmethylsiloxane 8

[0027] 2,2,4-Trimethyl-1,2-dihydroquinoline polymer 2

[0028] 6-Ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline 3

[0029] C5 petroleum resin 8

[0030] Nano carbon fiber 5

[0031] stearic acid 3 .

[0032]

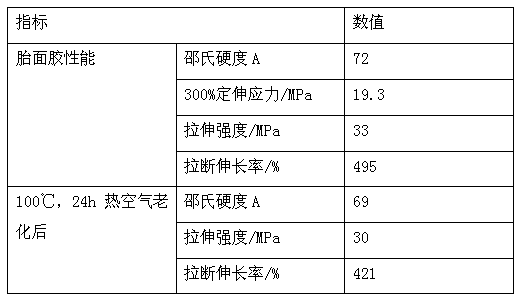

[0033] Manufacturing tire tread with the rubber of embodiment 1, its performance parameter is as follows:

[0034]

Embodiment 2

[0036] In the present embodiment, the rubber composition comprises the following components in parts by weight:

[0037] Epoxidized natural rubber: 60 SBR 60

[0038] Eucommia gum 20 EPDM rubber 10

[0039] Polyvinylsiloxane6 Polyphenylmethylsiloxane8

[0040] 2,2,4-Trimethyl-1,2-dihydroquinoline polymer 4

[0041] P.A-90 rubber tackifying resin 8

[0042] Nano carbon fiber 5

[0043] Oleic acid 3 .

Embodiment 3

[0045] In the present embodiment, the rubber composition comprises the following components in parts by weight:

[0046] Chlorinated natural rubber: 55 Butadiene rubber 60

[0047] Balata rubber 15 EPDM rubber 10

[0048] Polyvinylsiloxane6 Polyphenylmethylsiloxane8

[0049] 2,2,4-Trimethyl-1,2-dihydroquinoline polymer 4

[0050] P.A-90 rubber tackifying resin 8

[0051] Nano carbon fiber 5

[0052] Oleic acid 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com