Polymer production method and polymer cleaning device

A manufacturing method and a cleaning device technology, which are applied in the field of polymer manufacturing and polymer cleaning devices, can solve problems such as time-consuming and labor-intensive problems, and achieve the effects of reducing recycling losses and shortening the time of washing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

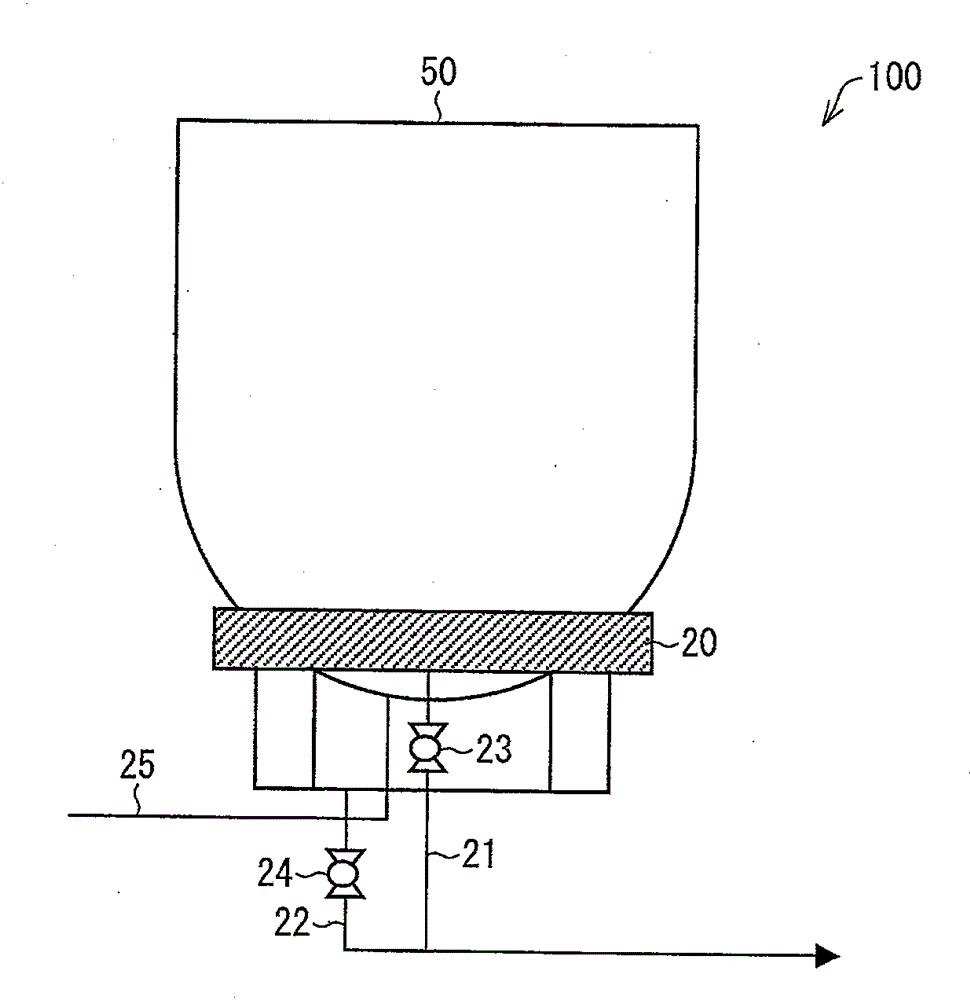

[0119] Inward volume 10m 36,091 kg of water, 100 kg of methyl cellulose aqueous solution (methyl cellulose concentration 1.43% by mass), 2,850 kg of vinylidene fluoride, 17.2 kg of di-n-propyl peroxydicarbonate, 35.1 kg of ethyl acetate were charged into the polymerization tank , Suspension polymerization was carried out at 25° C. for 11 hours. Cleaning of the polymerized vinylidene fluoride polymer is performed using a cleaning device having the same configuration as the cleaning device 100 shown in the above-mentioned embodiment. Accordingly, corresponding parts are described by appending appropriate part numbers.

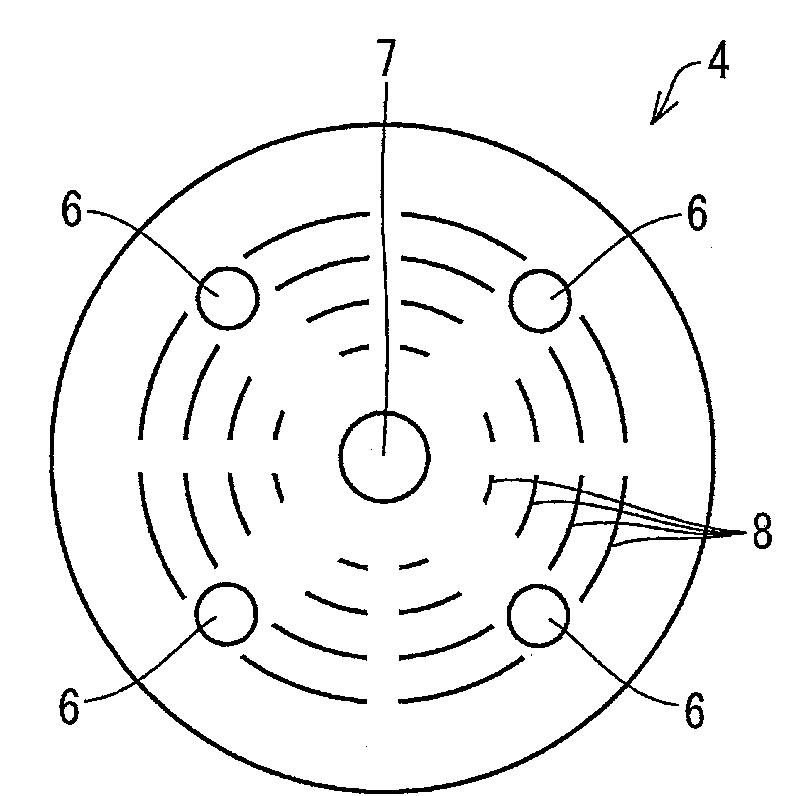

[0120] (filter material)

[0121] A sintered body of a SUS304 / SUS316L stainless steel wire mesh with 20, 30, 60, 200, 30, and 20 meshes in this order from the top was used. Among them, a porous plate is arranged at the lower part of the filter material.

[0122] First, after the polymerization is completed, the polymer slurry is transferred to the cleaning ta...

Embodiment 2

[0132] In Example 1, the same operation as in Example 1 was performed except that the first step was continuously repeated three times, followed by the second step, and the third step was continuously repeated twice. As a result, 2,353 kg of vinylidene fluoride polymer was obtained. In addition, as a result of measuring the color difference (b value), the b value was +1.89. Here, the b value is measured by heating and melting the dried vinylidene fluoride polymer powder at 240° C. for 10 minutes to form a pellet of 50 mm×50 mm×3 mm. The measurement of the b value was carried out by placing the center of the tablet in the opening of a color difference meter (ZE2000 manufactured by Nippon Denshoku Industries Co., Ltd.) and measuring the color tone. Wherein, the b value used in this embodiment is the b value in the L*a*b* colorimetric system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com