Efficient and energy-saving paint-water separation device

A high-efficiency energy-saving separation device technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of difficult discharge of paint residue, waste of water resources, heavy workload, etc., to reduce the occupied area, reduce the content of paint residue, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

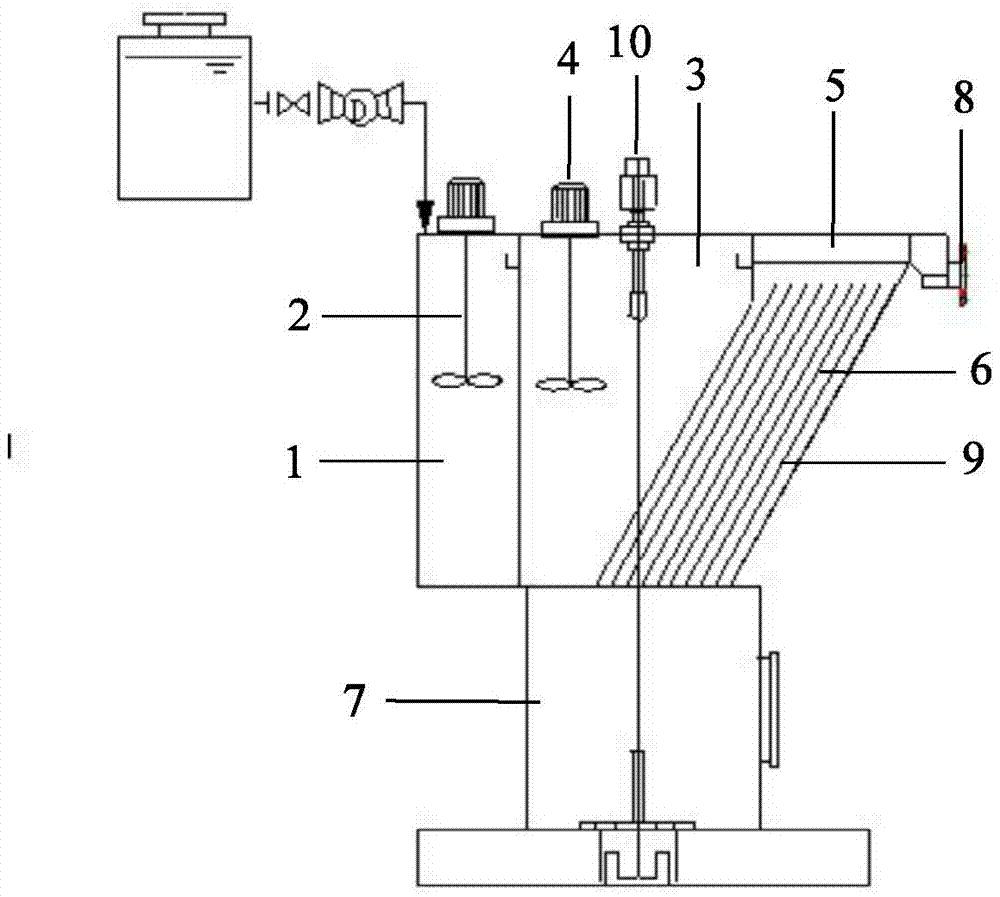

[0030] Specific embodiment: In this embodiment, the fast mixing tank 1, the slow mixing tank 3, and the sedimentation tank 5 are sequentially arranged in the same cavity shell without a cover, and a partition wall is welded between each pool body, and the top of the partition wall is slightly lower than the hollow. The top of the cavity shell wall. A stirrer is installed in the quick mixing tank 1, and the liquid inlet pipeline and the medicine inlet pipeline of the dosing system are connected from the top. A plurality of inclined plates 9 are equally spaced in the inclined plate settlement area 6 at the lower part of the sedimentation tank 5, and a water outlet 8 is provided on the top of the sedimentation tank 5 for the upper layer of clear water to overflow, and a cylindrical paint slag bucket 7 is welded below the sedimentation tank 5 to store the settled Paint residue.

[0031] In this embodiment, the fast mixing tank 1, the slow mixing tank 3, and the sedimentation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com