Tower crane anti-drop arm monitoring device, method and tower crane

A monitoring device and tower crane technology, applied in cranes and other directions, can solve problems such as failure to detect falling arms in time, safety accidents, etc., and achieve the effects of simple structure, avoidance of safety accidents, and cost generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

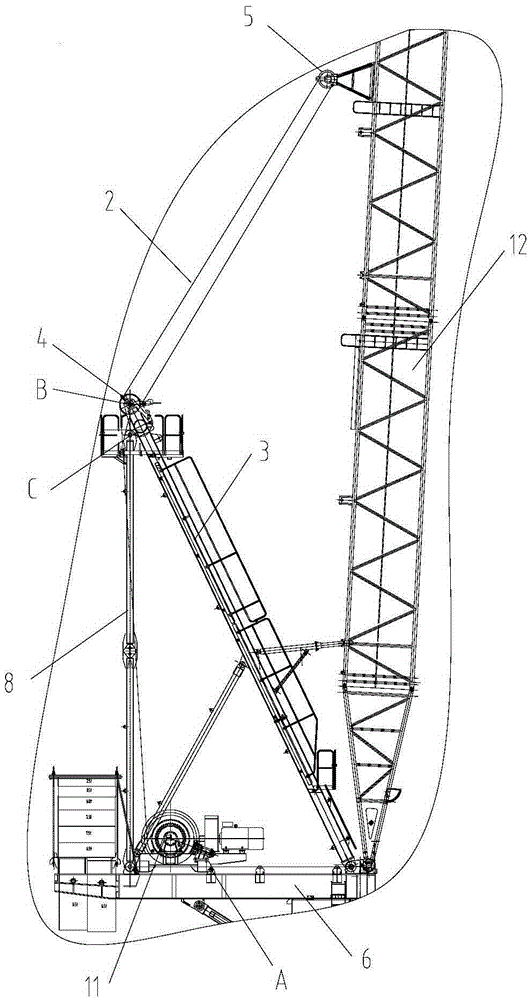

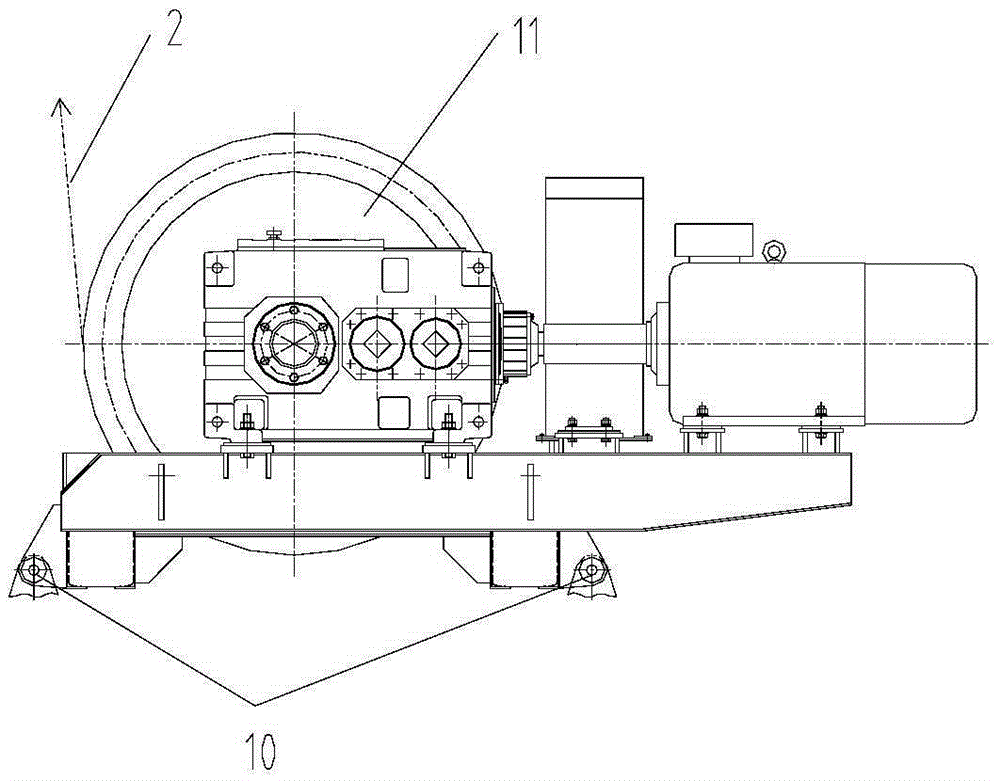

[0023] Please refer to figure 1 , The luffing steel wire rope 2 is wound out from the reel of the luffing mechanism, passes through the fixed pulley block 4 on the A-frame 3 , and walks around the movable pulley block 5 on the boom 12 . When the luffing mechanism is in operation, the distance between the moving and fixed pulley blocks can be changed by retracting and releasing the luffing wire rope 2 wound on the drum, thereby realizing the luffing of the luffing jib tower crane. For example, the controller can be a single-chip microcomputer or a PLC controller.

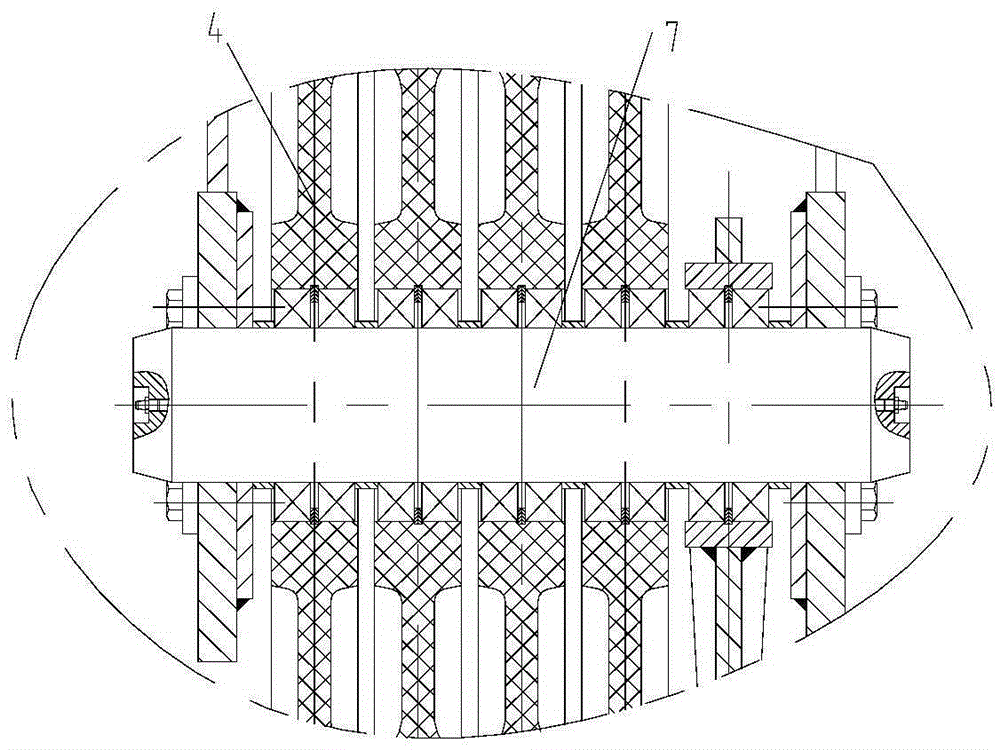

[0024] As a first aspect of the invention, please refer to Figure 1 to Figure 4 , provides a tower crane anti-drop arm monitoring device, including: a stress detection unit, used to obtain the stress value directly or indirectly reflecting the stress o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com