Method for destacking and stacking boxes and mechanisms and devices for implementing method

A stacking and box body technology is applied in the stacking of objects, destacking, transportation and packaging of objects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

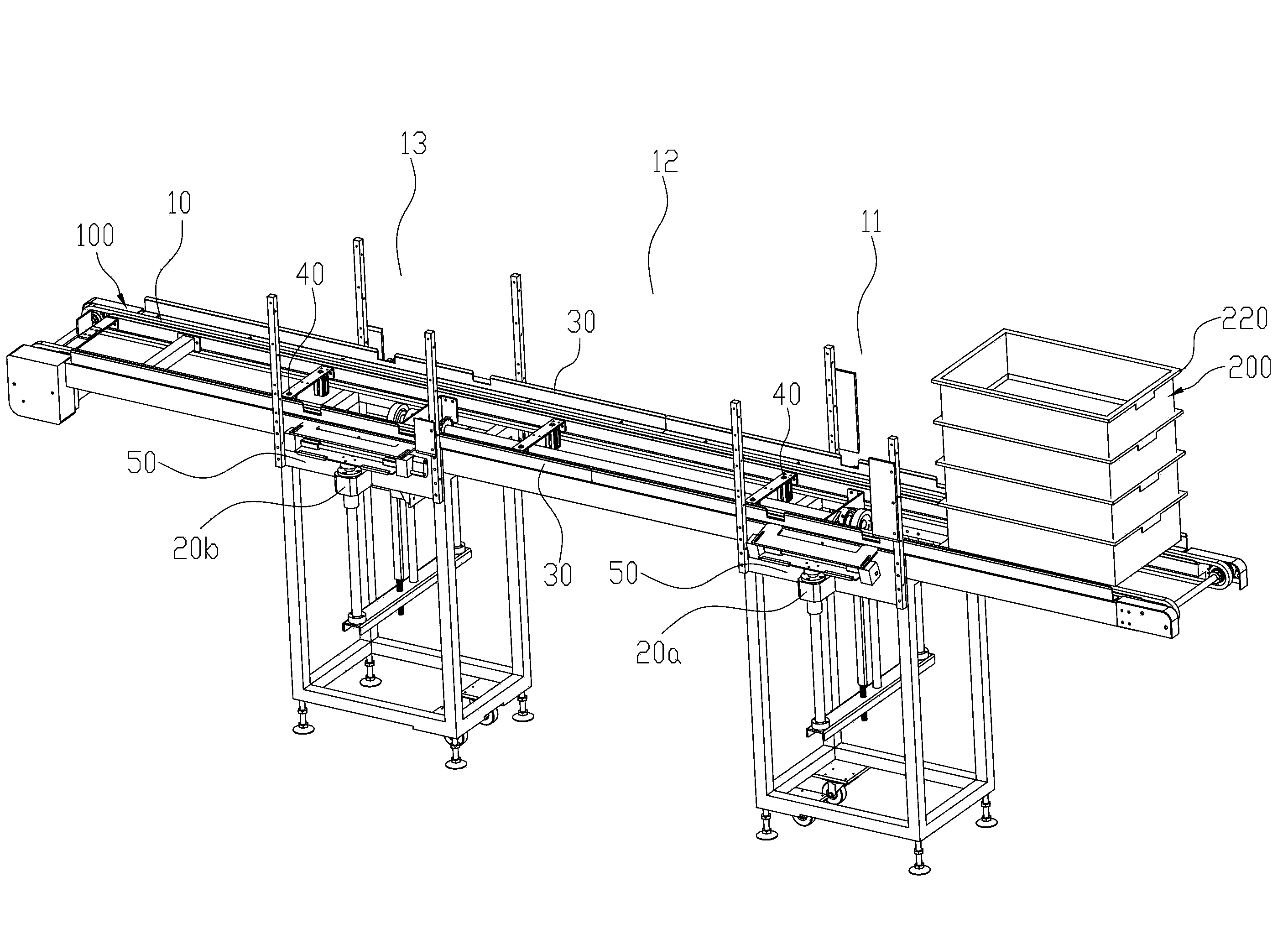

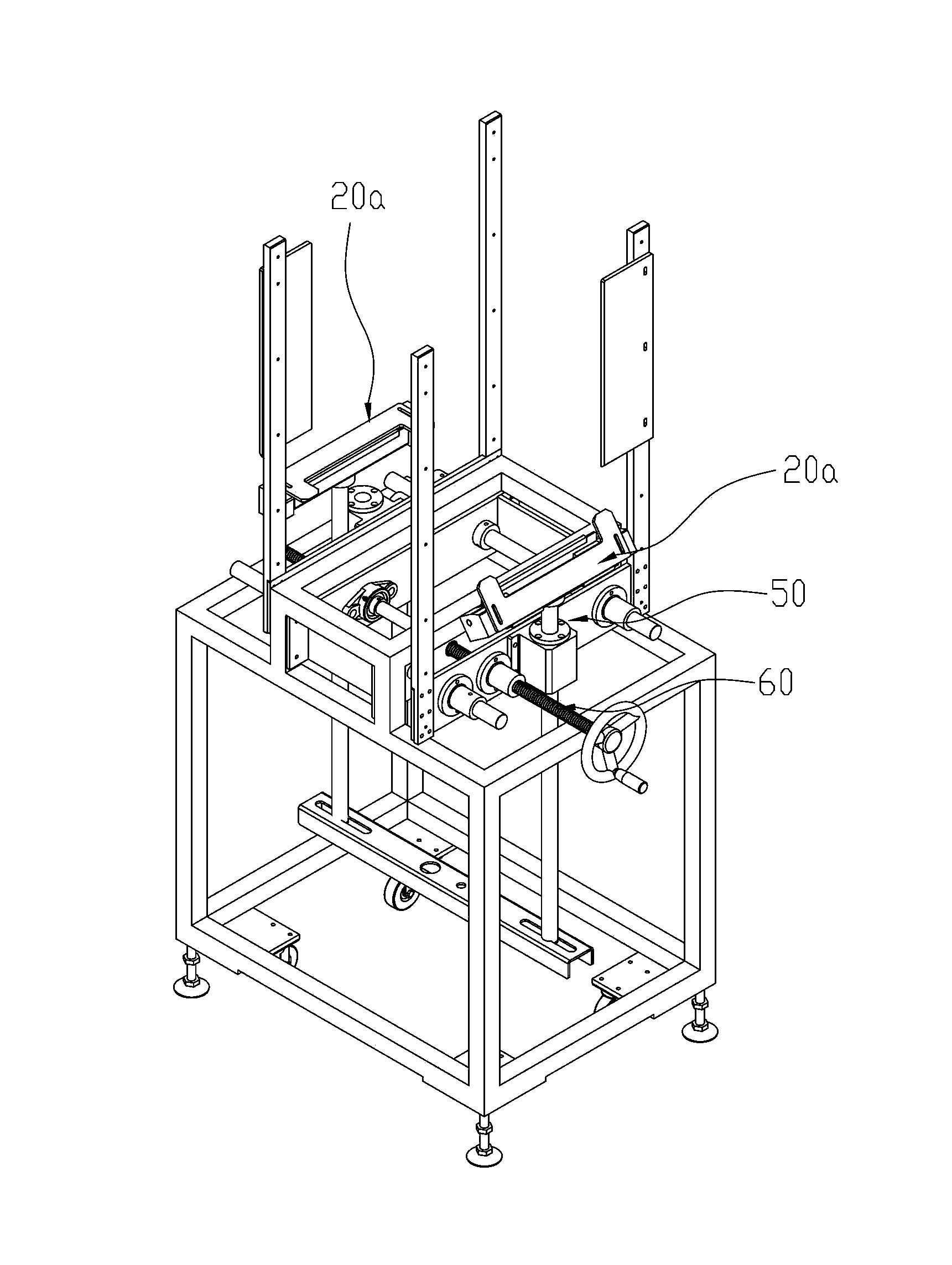

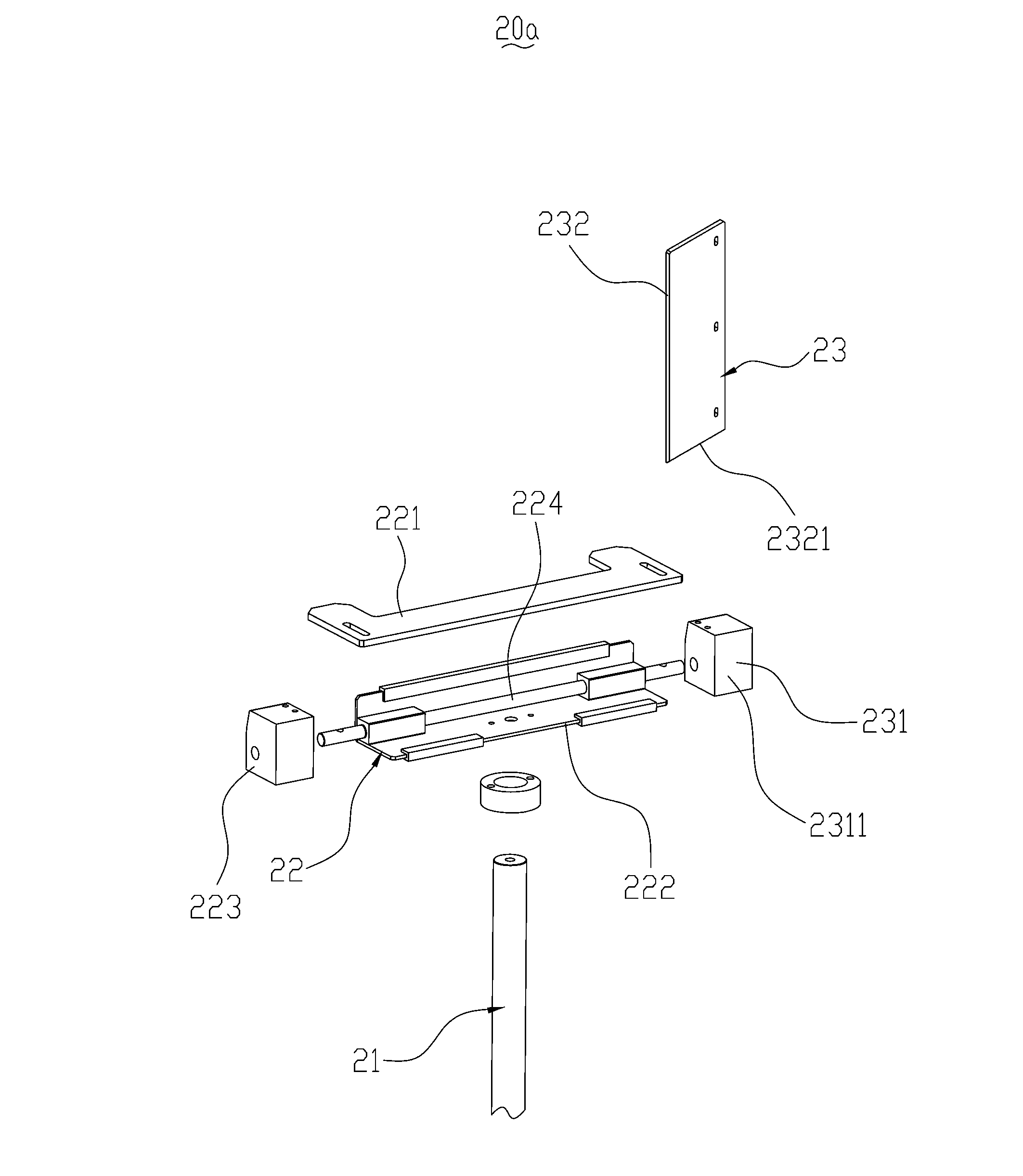

[0050] Please refer to figure 1 and figure 2 , The unpacking and stacking equipment 100 of the present invention is used to automatically place the empty box body 200 within the working range of the manipulator, and stack the box body 200 filled with products together. The equipment 100 includes: a conveyor belt 10 ; two dismantling and stacking mechanisms 20 a ; two dismantling and stacking mechanisms 20 b ; two baffle plates 30 ; six baffle rods 40 ; four mounting frames 50 ;

[0051] The conveyor belt 10 is used to transport the box body 200 . The conveyor belt 10 is sequentially provided with an empty container position 11 , a packing position 12 and a full container position 13 at intervals along the conveying direction. Several empty boxes 200 can be stacked on the conveyor belt 10 and transported to the empty box position 11, and these empty boxes 200 can be transported to the packing position 12 one by one; In the box body 200 of the packing position 12 ; the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com