Conveyor chain drop detection device and method

A detection device and conveyor chain technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient maintenance and inspection, affecting normal production, conveyor chain derailment, etc., to improve production safety, prevent The effect of a derailment accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

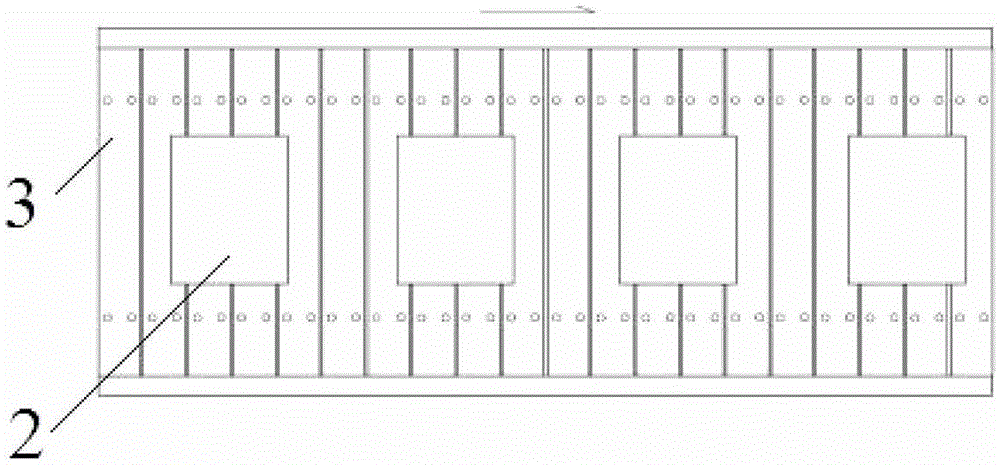

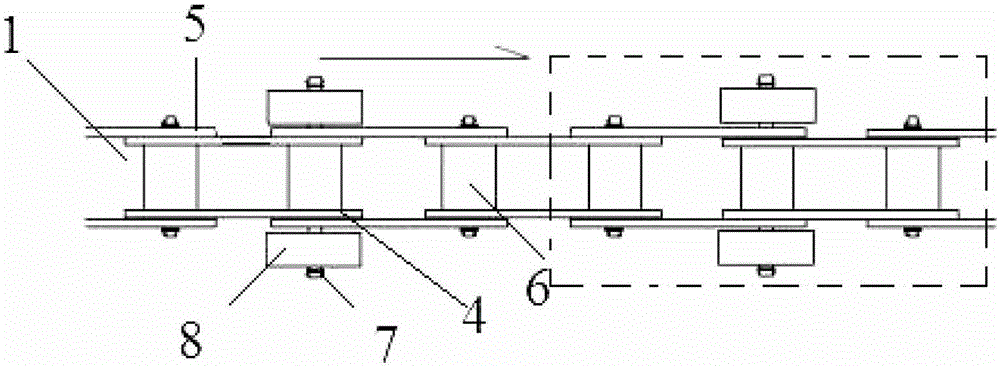

[0023] The device and method for detecting wheel drop of the conveyor chain proposed by the present invention are described in detail as follows in conjunction with the accompanying drawings and embodiments.

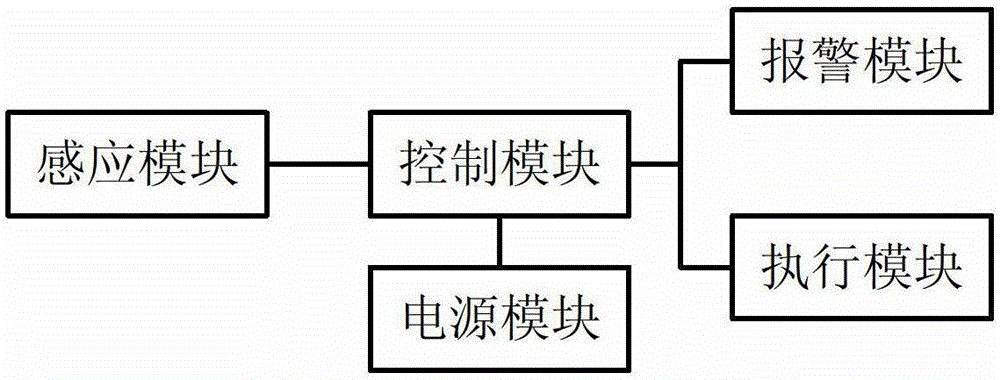

[0024] like image 3 As shown, the detection device for wheel drop of the conveyor chain of the present invention includes: a control module, an alarm module, an execution module, a power supply module, and at least one sensing module. Among them, the sensing module is usually set near the conveyor chain and within the sensing distance range of the sensing module, and the setting interval of the sensing module is selected according to the needs. The sensing module is connected with the control module for real-time feedback to the control module when the conveyor chain passes Send induction signal. The control module judges whether there is a wheel drop phenomenon according to the sensing signal sent by the sensing module, and sends a command signal to the execution modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com