Bolt dismounting and mounting locking device

A locking device and bolt disassembly technology, which is applied in hand-held tools, manufacturing tools, etc., can solve the problems such as the difficulty in fixing the disassembly bolts and the inability to fix them with a wrench, and achieve fast locking of the disassembly bolts with good locking effect , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

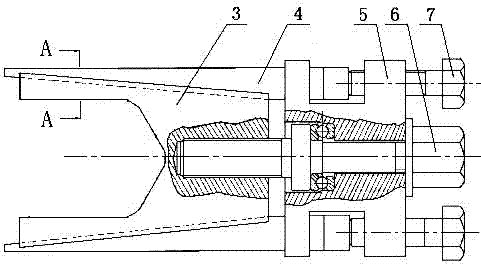

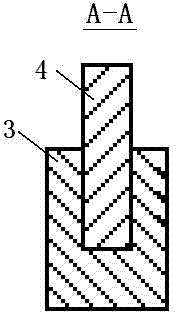

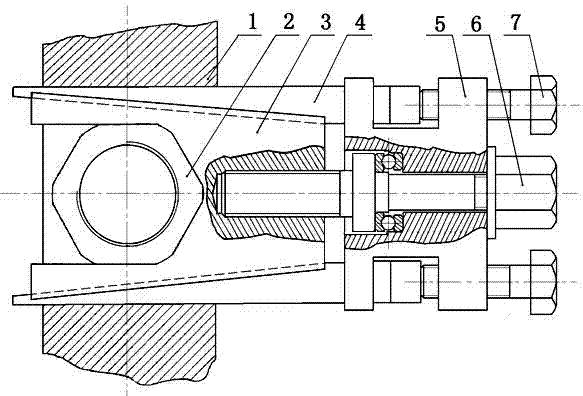

[0012] Example: Such as image 3 As shown, the operation and use steps of the present invention are as follows, clamp the nut 2 with the block 3, rotate the locking screw 6 on the support body 5, and push the locking block 4 forward, the body 1 is a casting, and the bolt is not necessarily at the center position. The side clearance between the sides of the two locking blocks 4 and the body 1 is different, and the side clearance adjustment can be completed through the support screw 7 on the support body 5, so that the body 1 and the locking device have no side clearance, reaching the lock nut 2 the goal of. The bolt can be easily removed by turning the bolt. After the assembly and disassembly is completed, the locking screw 6 on the support body 5 is reversely rotated to separate the clamping block 3 from the locking block 4, and the locking device withdraws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com