Laser welding plasma side suction negative pressure device and laser welding system

A laser welding and plasma technology, used in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of large air intake, poor plasma suppression effect, limited vacuum degree of negative pressure chamber, etc., to improve the vacuum degree, solve the poor anti-metal splash effect, and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] From a theoretical analysis, compared with traditional welding methods, high-power laser welding has the advantages of fast welding speed, small deformation after welding, and good quality of welded joints. With the maturity of ultra-high power and high beam quality industrial laser technology, the in-depth study of the interaction mechanism between laser and materials, and the continuous innovation of laser welding methods and process technologies, laser welding has great potential in large and thick plates. Due to the breakthrough application of high-power lasers in the manufacture of major equipment such as ships and nuclear power, and the limitation of the size of workpieces by vacuum chambers in the electron beam welding method, it provides a good opportunity for the breakthrough of high-power lasers in large and thick plates. Invention came into being.

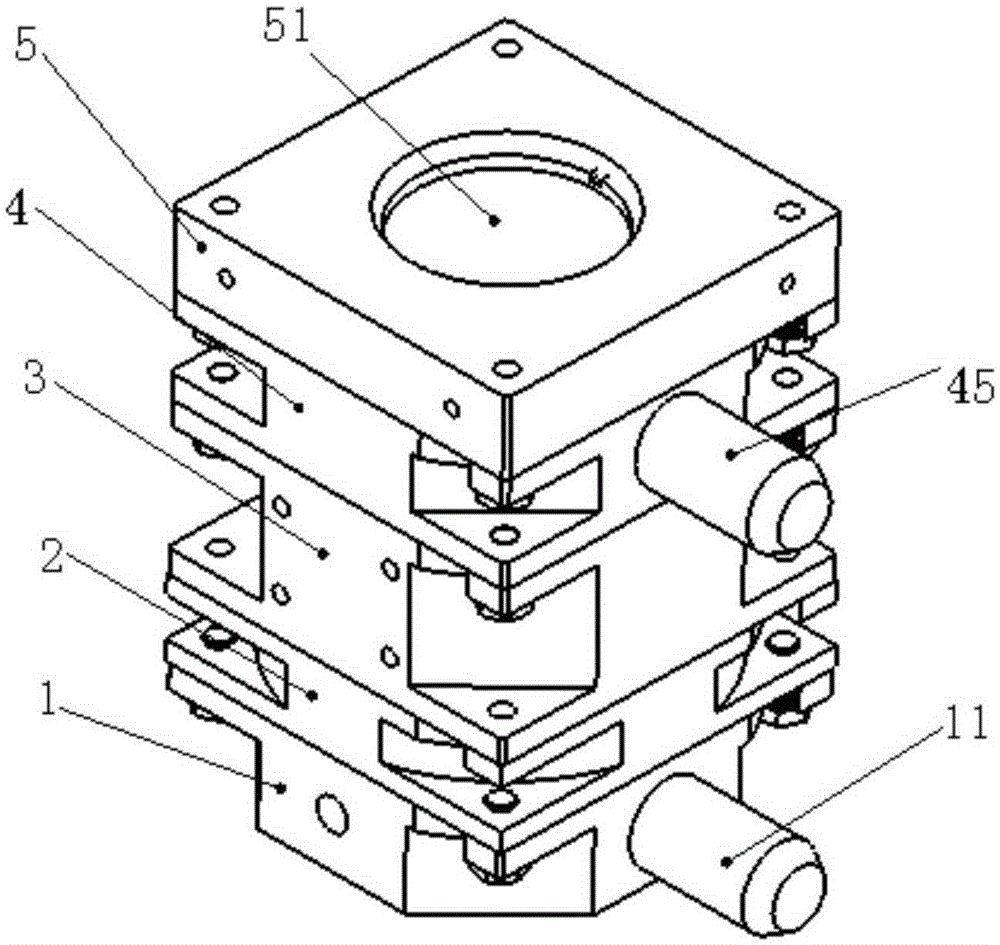

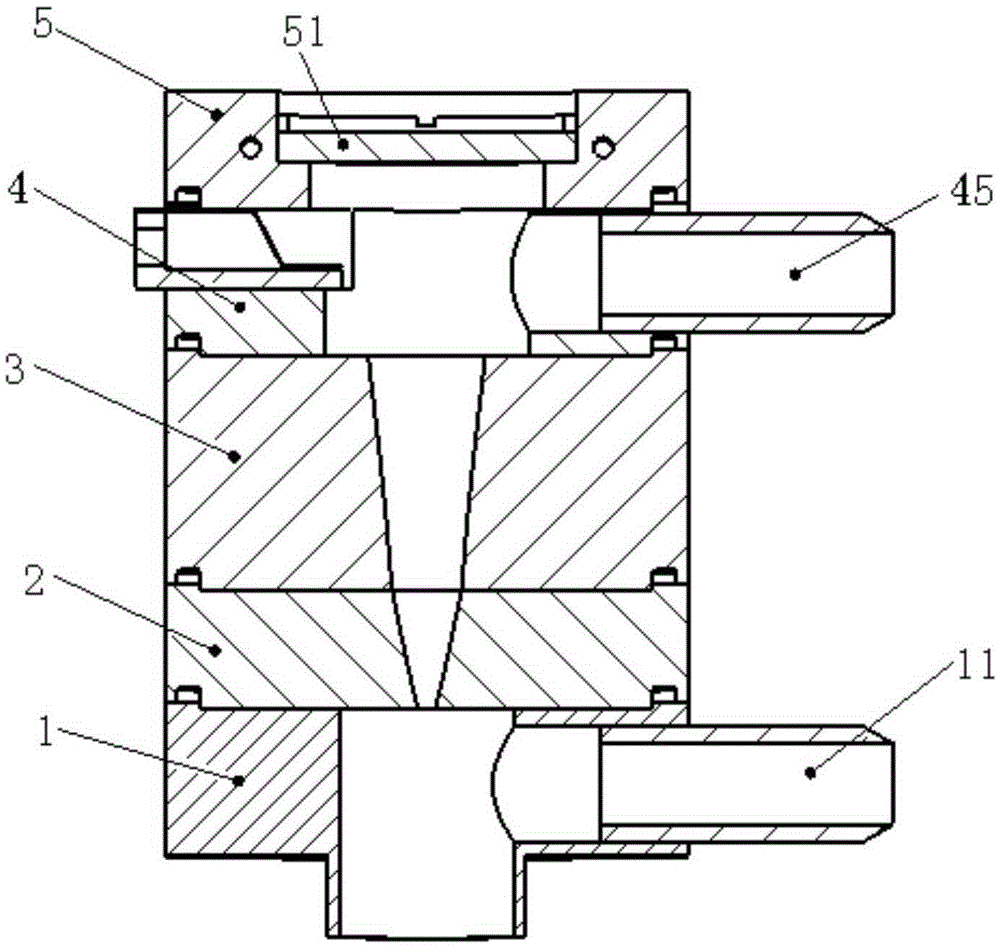

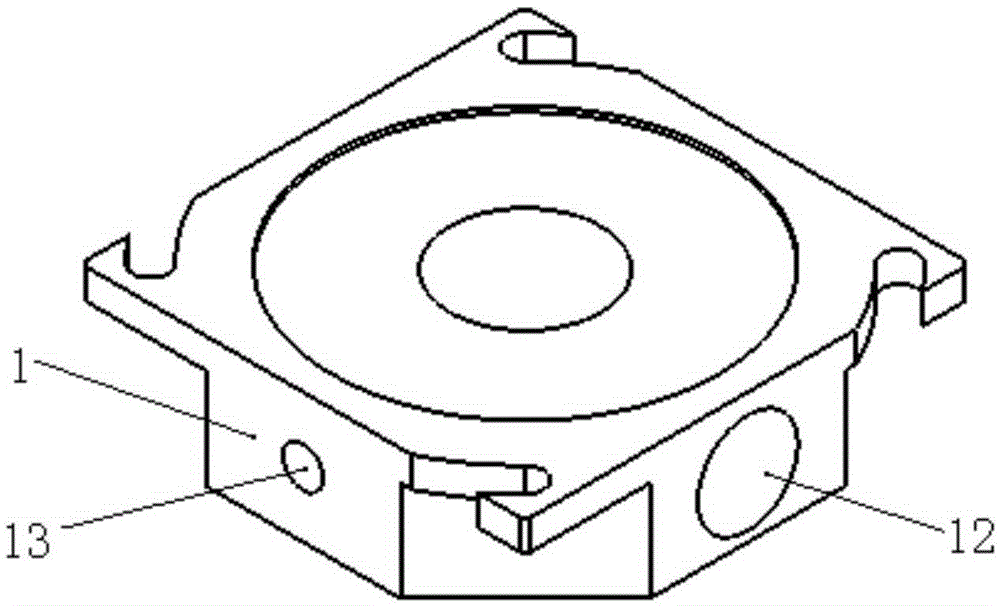

[0046] The laser welding plasma side suction negative pressure device of the present invention is applied to a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com