Large combined dual-jacking mould structure

A combined, ejector mechanism technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problem that the upper mold cannot be demoulded, etc., to reduce processing costs and reduce processing costs. Repair cost, weight and size reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

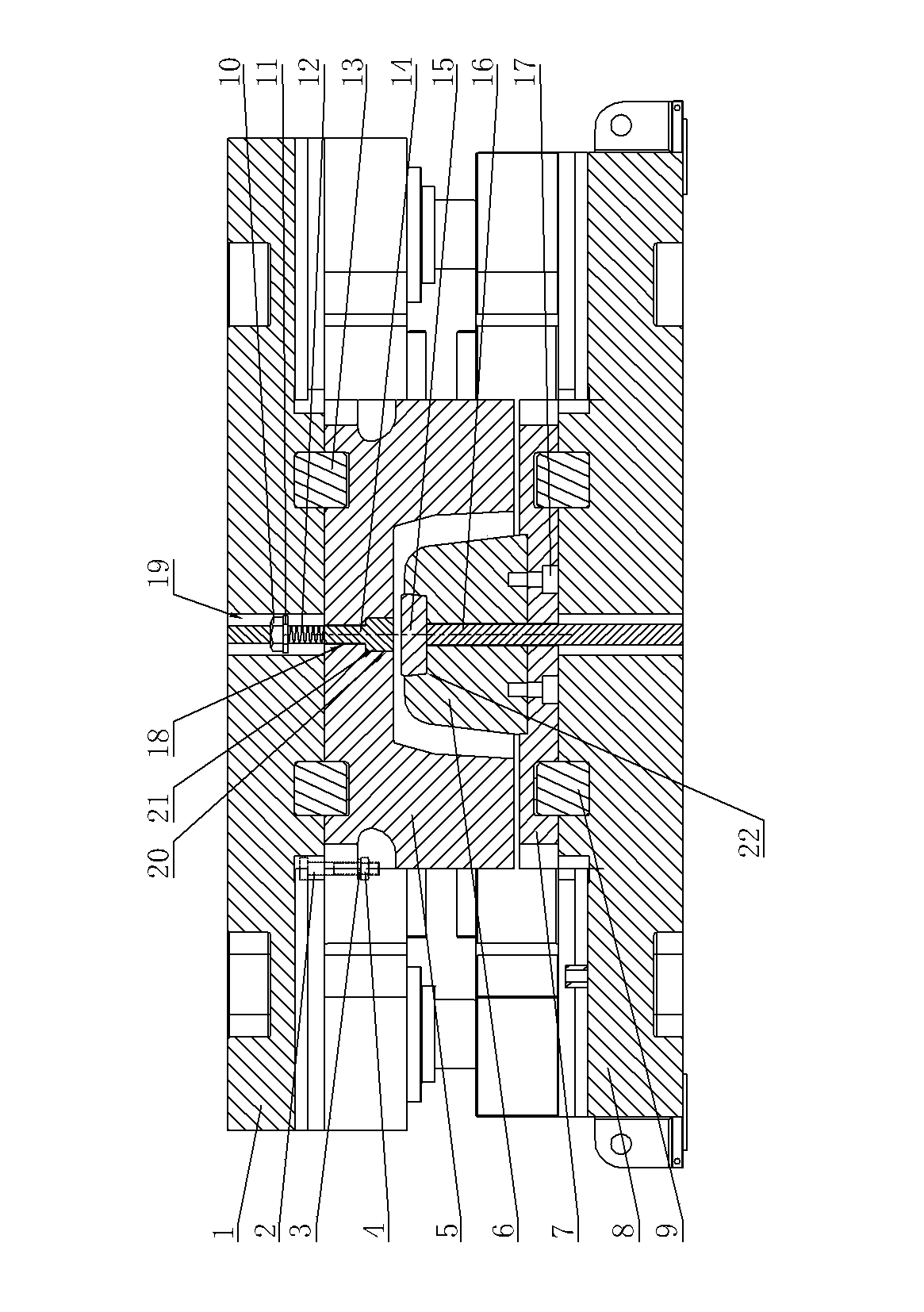

[0019] See figure 1 , the mold of the present invention comprises an upper mold structure and a lower mold structure, the upper mold structure includes an upper mold base 1 and an upper mold 5, the upper mold 5 is installed under the upper mold base 1, and a lower mold ejection mechanism is installed in the lower mold structure, the upper mold The upper mold ejection mechanism is installed in the mold structure. The upper mold ejection mechanism includes an upper ejector rod 14 and a compression spring 12. The upper ejector rod 14 passes through the upper mold 5 and the upper ejector rod of the upper mold base 1 from bottom to top in sequence. Holes 18, 19, the bottom flange 20 of the upper die 14 and the groove 21 of the upper mold 5 are clearance fit, and the aperture of the upper ejector mounting hole 19 of the upper die base 1 is larger than that of the upper ejector mounting hole 18 of the upper die 5 Aperture, the upper ejector rod 14 is located in the part of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com