Bearing, shaft box and accessory washing device and method

A cleaning device and axle box technology, applied to cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of low pass rate of cleanliness testing, frequent replacement of cleaning agents, and high labor intensity of workers and other problems, to achieve the effect of reducing the consumption of procedures and cleaning agents, good flushing effect and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

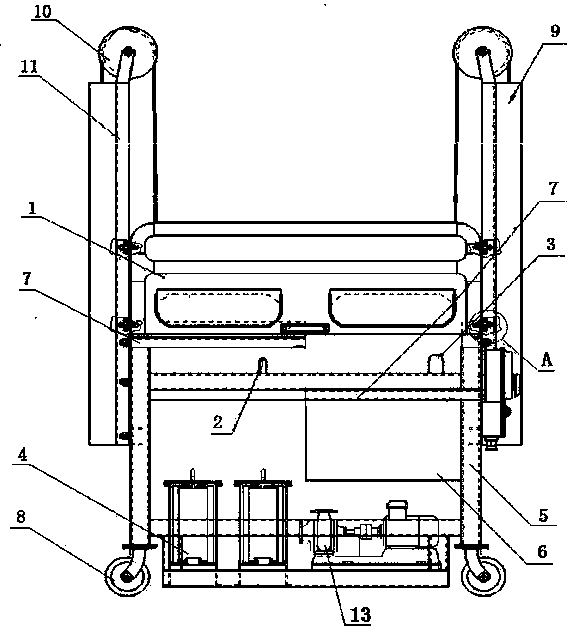

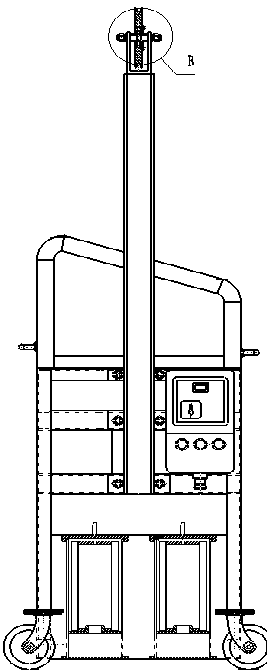

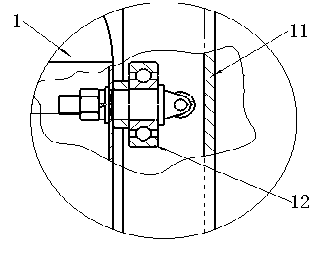

[0041] combine Figure 1 to Figure 5 The cleaning device for bearings, axle boxes and accessories of the present invention will be described in detail.

[0042] Such as figure 1 with figure 2 As shown, the cleaning device for bearings, axle boxes and accessories of the present invention includes a console frame 5, a cleaning agent box 6, universal wheels 8, a transparent splash guard 1, and a high-pressure cleaning gun 14 (not shown in the figure) ), high-pressure air gun (not shown in the figure), high-pressure centrifugal pump (not shown in the figure), filter system 4.

[0043] The cleaning agent box 6 is installed on the console frame 5, and two mesh partitions 7 are arranged on the top of the cleaning agent box 6, the left side is low and the right side is high, so as to be divided into two relatively independent areas; the cleaning agent box 6 The left side of the bottom is shallow and the right side is deep, and the cleaning agent is placed deeper in the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com