Banana relaxation screen without main beam

A relaxation sieve and banana technology, applied in the direction of sieving, solid separation, grille, etc., can solve the problems of clogged sieve holes, low screening efficiency, high content, etc., to reduce wearing parts, high screening efficiency, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings

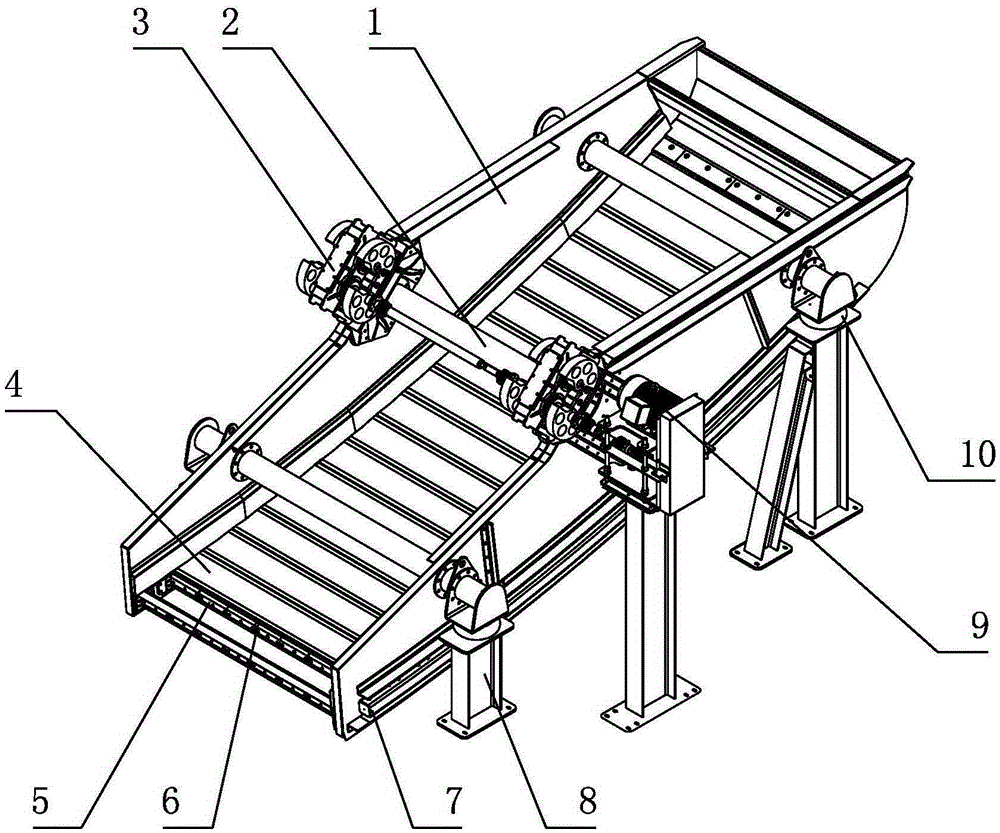

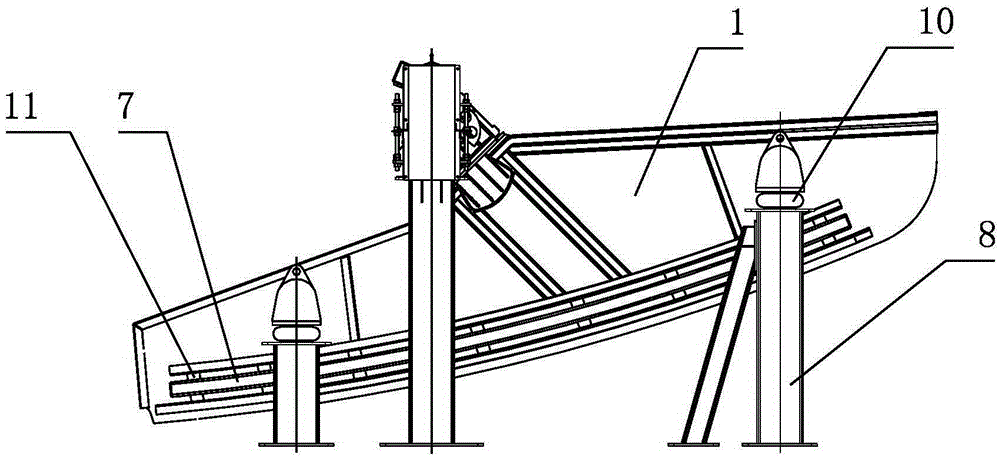

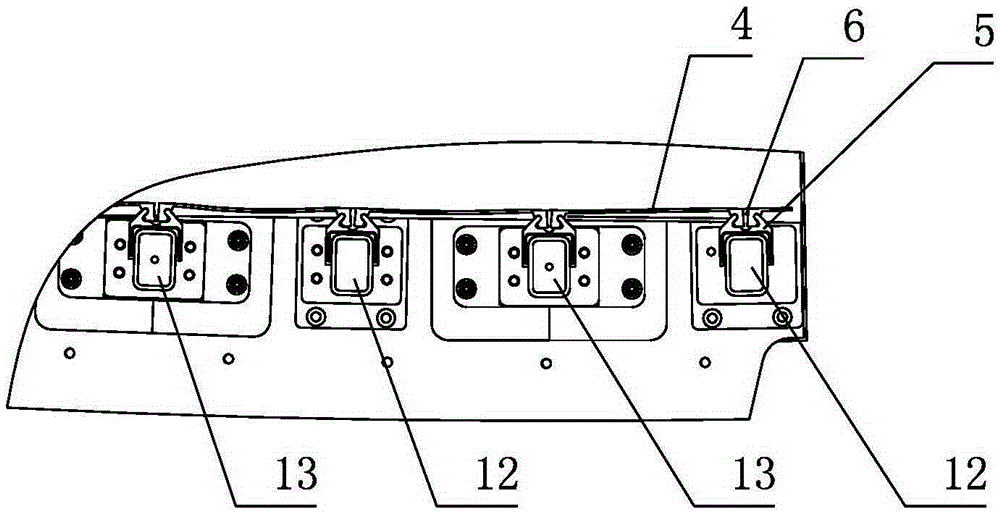

[0025] Such as Figure 1~3 As shown, this non-main beam banana relaxation screen includes a screen body, a bracket, a vibration excitation device and a driving device 9. The outside of the screen body is supported by a plurality of brackets 8 with different heights. The shock spring 10 is used to cushion the impact of the screen body on the ground when it is working. The screen body includes a main screen frame 1, a floating screen frame and a screen plate 4. The main screen frame 1 includes a left side plate, a right side plate and a number of fixed beams 13 connected between the bottoms of the two side plates. The floating screen frame includes a balance beam 7 1. Floating crossbeam 12 and balance beam 7 are longitudinally arranged along the bottom of the side plate of main screen frame 1, and are connected to the side plate through resonant spring 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com