Gas-liquid distributor for fluidized bed reactor

A technology of ebullating bed reactors and gas-liquid distributors, applied in chemical instruments and methods, treatment with moving solid particles, chemical/physical processes, etc., can solve problems such as reduced reliability, lack of gas-liquid mixing structure, pulsating flow, etc. , to achieve the effects of not being easy to block the catalyst, ensuring long-term operation, and stable gas-liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

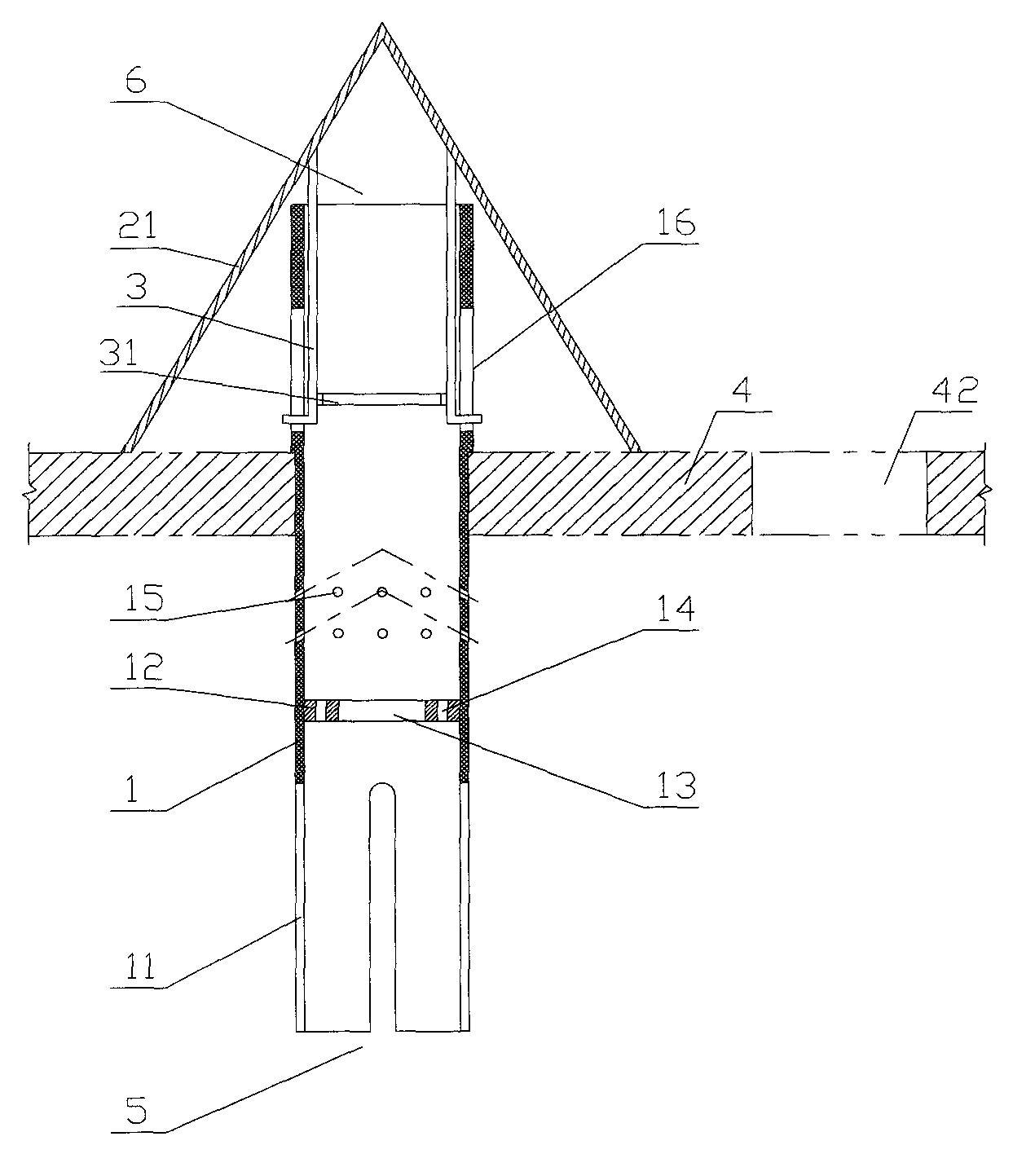

[0028] figure 1 It is a structural schematic diagram of the first embodiment of the gas-liquid distributor for a three-phase ebullating bed reactor of the present invention. The cap 2, the connecting leg 3 and the distribution plate 4 are composed.

[0029] The central pipe 1 passes through the distribution plate opening on the distribution plate 4 (represented by the distribution plate opening 42 in the figure), and is divided into upper and lower sections by the distribution plate 4. The upper section and the lower section are bounded by the upper surface of the distribution plate 4 , the central tube 1 can be processed through the overall circular tube, the diameter of the upper section is generally 2-8mm larger than the diameter of the lower section, and an annular platform is formed between the upper section and the lower section, which is mainly used for the positioning and installation of the central tube 1 and the distribution plate 4.

[0030]The lower section of the...

Embodiment 2

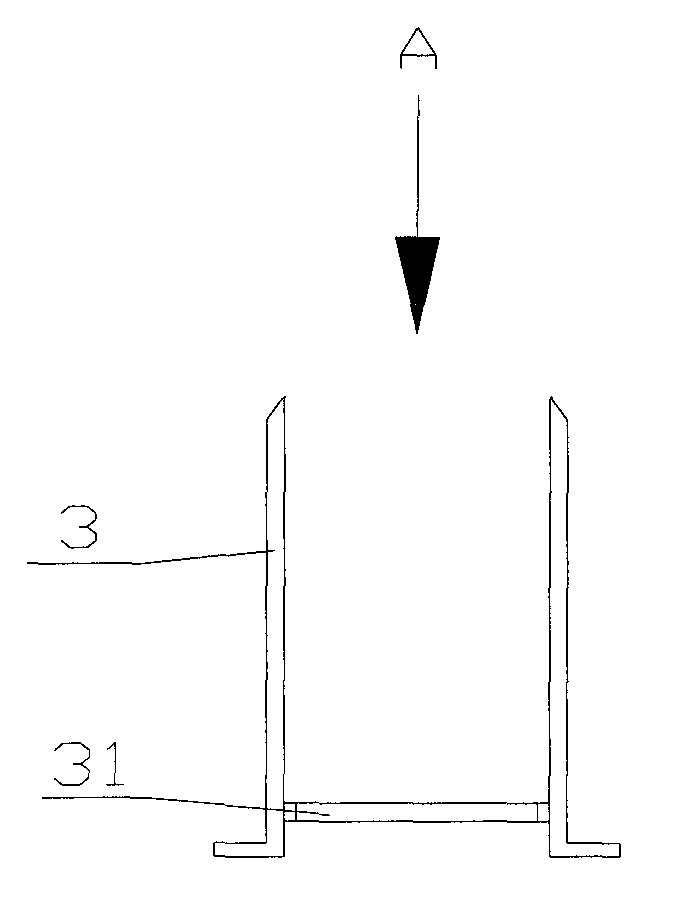

[0037] figure 2 It is a structural schematic diagram of the second embodiment of the gas-liquid distributor for a three-phase ebullating bed reactor of the present invention. The difference between embodiment 2 and embodiment 1 is that the structure of the bubble cap is different and no trapezoid is set in embodiment 2. Ring platform, the rest of the structure is the same. Of course, Embodiment 2 can also be provided with a trapezoidal ring platform to improve the sealing performance and better prevent backflow. In Embodiment 2, the conical bubble cap 21 is also a cover with an open bottom, which is conical. The cone angle of the conical structure should generally be smaller than the accumulation angle of the catalyst, and the accumulation angle of the catalyst is generally 45-70°. Compared with Embodiment 1, the structure of the conical bubble cap 21 is simpler, but the opening ratio of the distribution plate will be reduced. In Embodiment 2, the bottom periphery of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com