A converter automatic testing system and method

An automatic test system and automatic test technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of insufficient low-voltage test coverage, no voltage sensor, current sensor test, slow test speed, etc., to achieve comprehensive and effective fault detection , avoid the inconsistency between parameter setting and measurement results, and avoid the effect of human judgment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

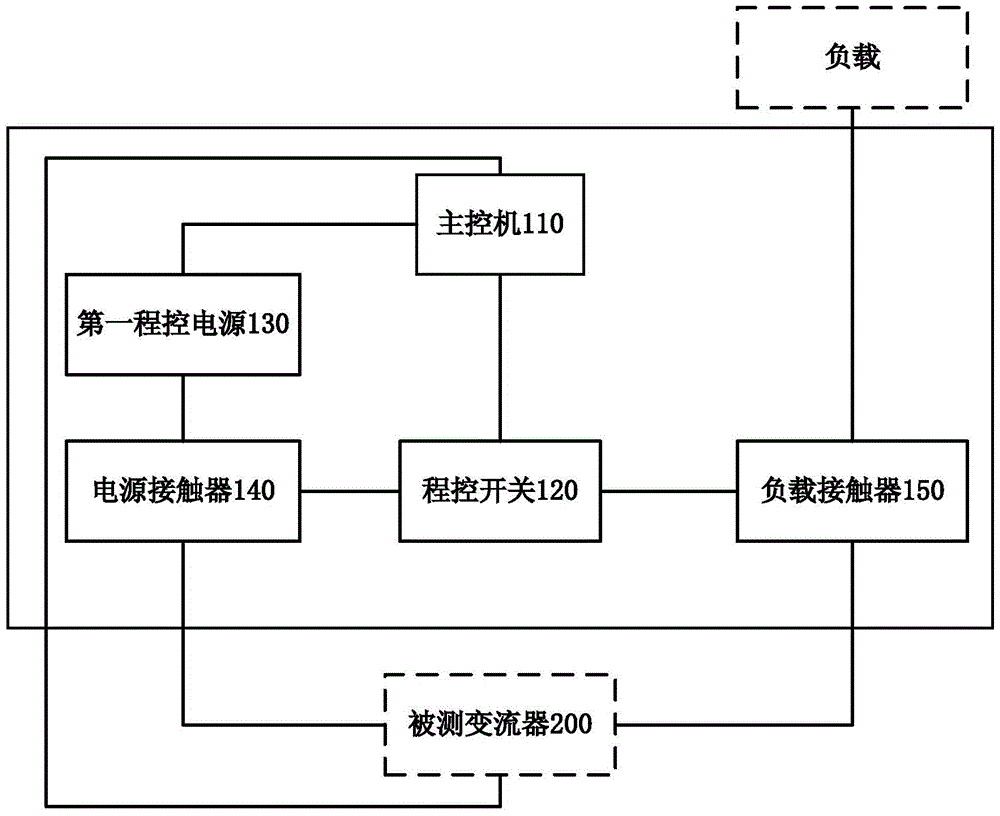

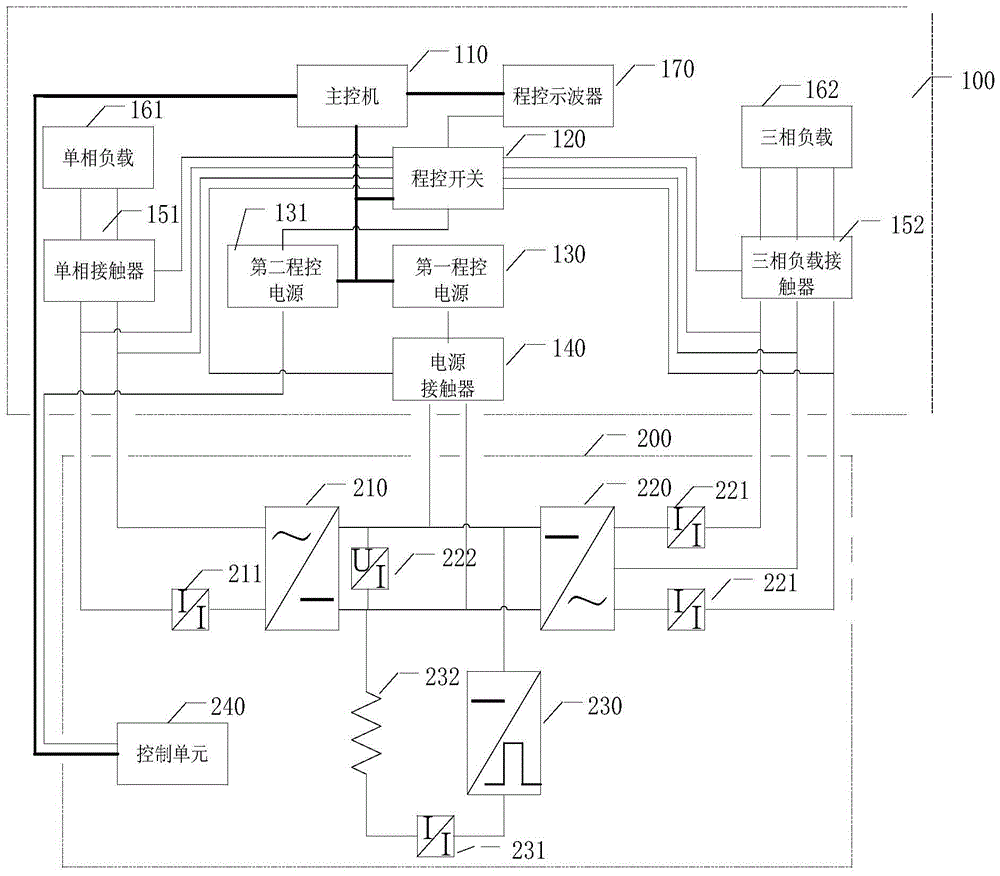

[0031] like figure 1 Shown is a schematic diagram of the composition and structure of the converter automatic test system 100 provided by the present invention, which includes:

[0032] The main control machine 110 is used to issue control instructions, control the operation of the unit modules in the test system and the control modules in the tested converter, and use the converter to perform automatic detection and obtain detection parameters;

[0033] The program-controlled switch 120, which is coupled to the main control machine 110, is used to select the route in the test system according to the control command issued by the main control machine 110, start the unit module operation on the selected route or obtain the tested converter through the selected route detection parameters;

[0034] A first program-controlled power supply 130, which is coupled to the main control computer 110, is used to set power parameters according to the control instructions issued by the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com