High-performance sliding meshing sleeve

A meshing sleeve, high-performance technology, applied in portable lifting devices, components with teeth, belts/chains/gears, etc., can solve the problems that cannot satisfy the transmission stability of the whole vehicle, ride comfort and safety, etc., and achieve good results , Improve the torque transmission capacity, increase the effect of meshing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

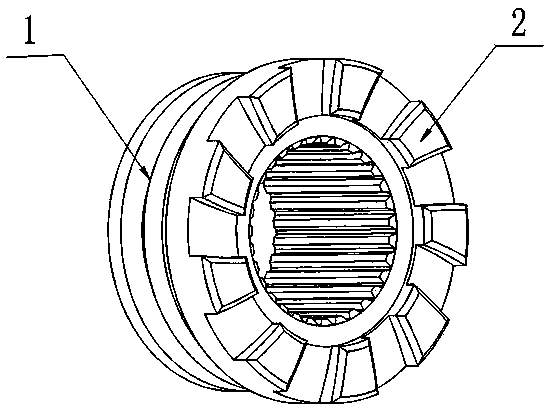

[0011] Such as figure 1 As shown, a high-performance sliding engagement sleeve includes a sliding engagement sleeve body (1), and the end surface of the sliding engagement sleeve body (1) is provided with Oerlikon end face meshing teeth (2).

[0012] The Oerlikon end-face meshing teeth (2) are designed with equal height teeth.

[0013] The number of Oerlikon end face meshing teeth (2) is 9.

[0014] Of course, the above description is not a limitation of the present invention, and the present invention is not limited to the above examples. Any changes, modifications, additions or substitutions made by those of ordinary skill in the art within the essential scope of the present invention shall belong to The protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com