Sliding engaging sleeve of gearbox

A technology of meshing sleeve and gearbox, which is applied in transmission parts, transmission control, gear lubrication/cooling, etc., can solve the problem of not satisfying the transmission stability of the whole vehicle, riding comfort and safety, and affecting the stability and reliability of power transmission. , power output terminal and other issues, to achieve the effect of stable force, long service life and increased meshing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0019] The present invention provides a gearbox sliding meshing sleeve aiming at the problems that the end surface meshing teeth of the existing sliding meshing sleeve have a straight tooth structure and are easy to be out of gear after meshing with the driving gear.

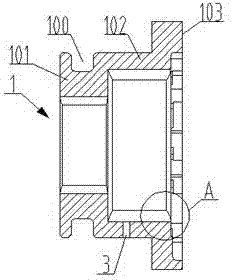

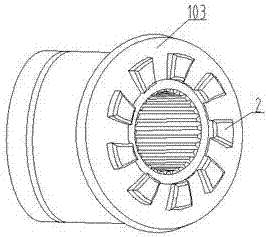

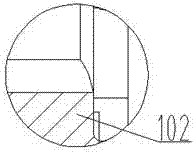

[0020] like figure 1 As shown, the embodiment of the present invention provides a sliding engagement sleeve for a gearbox, including a sliding sleeve body 1, the outer ring of the sliding sleeve body 1 is provided with a shift fork groove 100, and the center of the sliding sleeve body 1 is provided with a center A through hole, the central through hole includes a sliding section 101 and an engaging section 102, the inner diameter of the sliding section 101 is smaller than the inner diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com