A Repair and Strengthening Method for Corroded Reinforced Concrete Beams Based on Arch Effect

A technology of reinforced concrete beam and arch effect, which is applied in building maintenance, construction, building structure, etc., can solve the problems of long concrete curing period, great influence, and improve the residual bearing capacity of corroded beams, so as to reduce the construction period and reduce the repair. cost, the effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

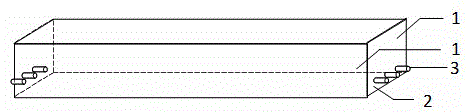

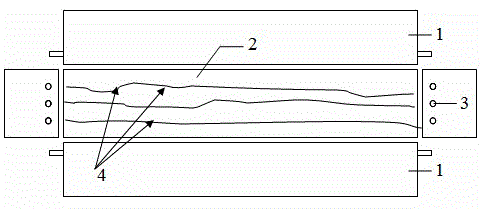

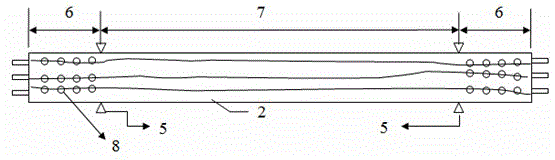

[0024] Embodiment 1: as Figure 1-6 Shown, a kind of method for repairing and strengthening the corroded reinforced concrete beam based on arch effect, the concrete steps of described method are as follows:

[0025] A. Clean the concrete surface in the 10mm wide area of the rust swelling crack in the anchorage area on the bottom surface;

[0026] B. Set a filling port every 25mm for the rust swelling crack, and fill the epoxy resin into the inside of the rust swelling crack in the anchorage area from the reserved filling port by the low-pressure filling method, and perform maintenance;

[0027] C, the thickness is h fib The carbon fiber cloth covering the bottom surface of the anchorage area and the bottom surface of the area between the fulcrums, and epoxy resin is used as a binder, and only the carbon fiber cloth located in the anchorage area is bonded to the bottom surface of the reinforced concrete beam;

[0028] D. Wrap 1 layer of carbon fiber cloth on the top surfac...

Embodiment 2

[0030] Embodiment 2: as Figure 1-6 Shown, a kind of method for repairing and strengthening the corroded reinforced concrete beam based on arch effect, the concrete steps of described method are as follows:

[0031] A. Clean the concrete surface in the 10mm wide area of the rust swelling crack in the anchorage area on the bottom surface;

[0032] B. Set a filling port every 35mm for the rust swelling crack, and fill the epoxy resin into the inside of the rust swelling crack in the anchorage area from the reserved filling port by the low-pressure filling method, and perform maintenance;

[0033] C, the thickness is h fib The carbon fiber cloth covering the bottom surface of the anchorage area and the bottom surface of the area between the fulcrums, and epoxy resin is used as a binder, and only the carbon fiber cloth located in the anchorage area is bonded to the bottom surface of the reinforced concrete beam;

[0034] D. Wrap 2 layers of carbon fiber cloth on the top surfa...

Embodiment 3

[0036] Embodiment 3: as Figure 1-6 Shown, a kind of method for repairing and strengthening the corroded reinforced concrete beam based on arch effect, the concrete steps of described method are as follows:

[0037] A. Clean the concrete surface in the 10mm wide area of the rust swelling crack in the anchorage area on the bottom surface;

[0038] B. Set a filling port every 50mm for the rust swelling crack, and fill the epoxy resin from the reserved filling port into the inside of the rust swelling crack in the anchorage area by the low-pressure filling method, and perform maintenance;

[0039] C, the thickness is h fib The carbon fiber cloth covering the bottom surface of the anchorage area and the bottom surface of the area between the fulcrums, and epoxy resin is used as a binder, and only the carbon fiber cloth located in the anchorage area is bonded to the bottom surface of the reinforced concrete beam;

[0040] D. Wrap 1 layer of carbon fiber cloth on the top surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com