A method for repairing notch cracks in brittle materials

A technology of brittle materials and repair methods, which is applied in the field of notch crack repair of brittle materials, can solve problems such as material failure, shortening service life, and affecting material functional integrity, and achieve good bearing capacity, restore bearing capacity, and inhibit rapid expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

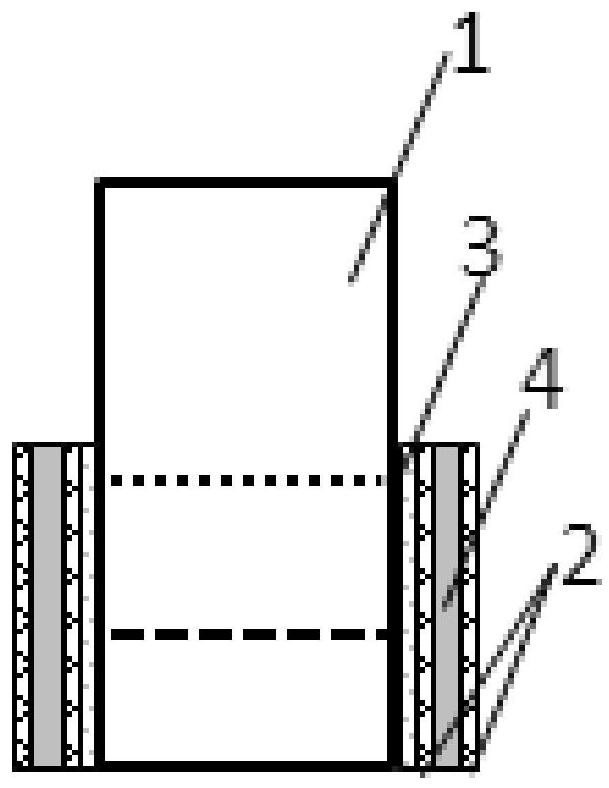

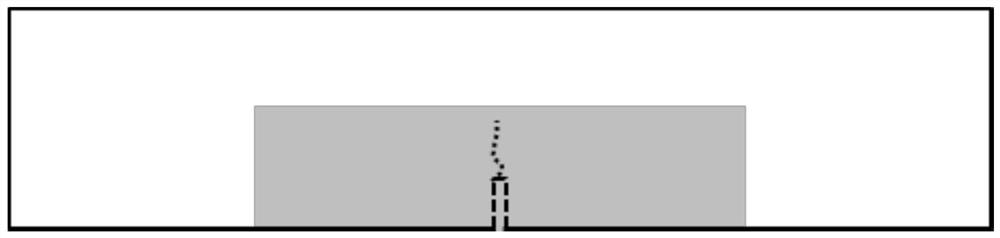

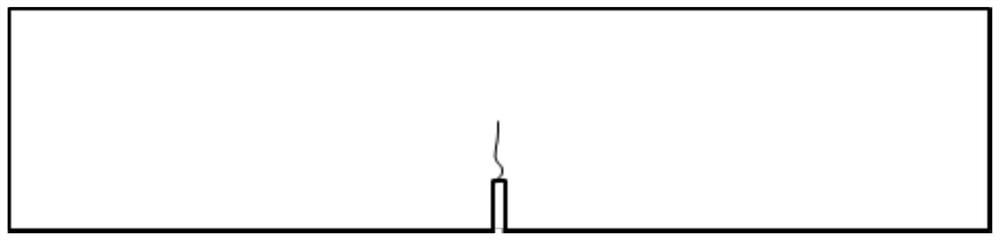

[0030] combined with Figure 1-3 As shown, a method for repairing a notch crack of a brittle material, the matrix 1 is a granular composite brittle material, and the method for repairing a groove crack thereof comprises the following steps:

[0031] The first step is surface pretreatment. Gently wipe the surface of the material with absolute ethanol to remove surface dirt and dust.

[0032] The second step is to cut the patch. Cut two identical square patches from the carbon fiber cloth coil. The size of the patch depends on the size of the material block to be repaired (9×18×80mm) and the length of the gap and crack ( 4mm and 5mm respectively). In order to completely cover the crack and ensure that the patch can share the load with the material without interface cracking, the size of the patch in this embodiment is determined to be 40mm long and 10mm wide.

[0033] The third step is to paint the primer 3, put the primer 3 resin main agent and curing agent in the container i...

Embodiment 2

[0040] A method for repairing a notch crack in a brittle material, wherein the substrate 1 is a particle-composite brittle material, and the method for repairing an opening crack in it comprises the following steps:

[0041] The first step is surface pretreatment. Gently wipe the surface of the material with absolute ethanol to remove surface dirt and dust.

[0042] The second step is to cut the patch. Cut 2 identical square patches from the carbon fiber cloth coil. The size of the patch depends on the size of the sample to be repaired 9×18×80mm and the length of the gap and crack is 4mm and 6mm respectively. . In order to completely cover the crack and ensure that the patch can share the load with the material without interface cracking, the size of the patch in this embodiment is determined to be 40mm long and 12mm wide.

[0043] The third step is to paint the primer 3, put the primer 3 resin main agent and curing agent in the container in a ratio of 1:1, stir evenly, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com