Trailing suction device for dredger

A technology of dredging boats and raking suction, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve the problems of poor shell strength, easy deformation, and low work efficiency. Achieve the effect of eliminating manual work, increasing strength and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

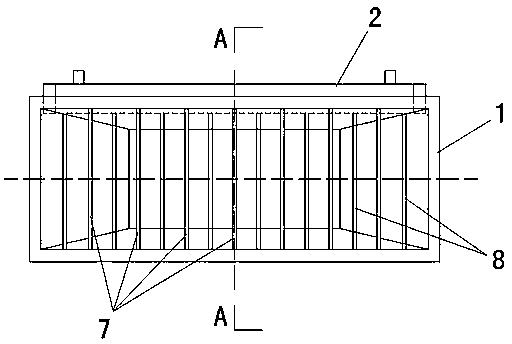

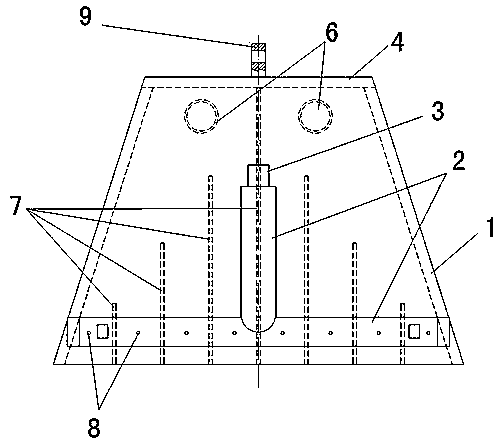

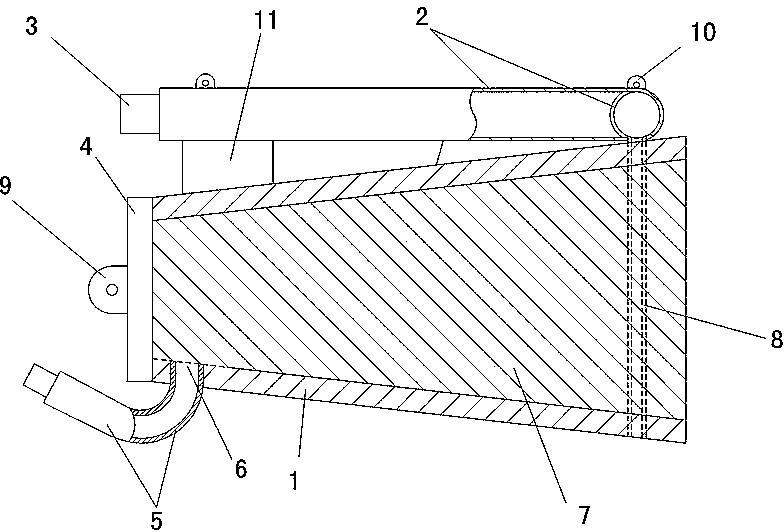

[0011] like figure 1 , 2 , 3, as shown: 1 is the rake shell, and the rake shell 1 is surrounded by the side panel and the rear cover 4 at the rear end, and there is a silt inlet at the front end of the rake shell 1, and there is a silt discharge outlet 6 under the rear end of the rake shell 1 , the discharge port 6 is connected with the sludge discharge pipe 5.

[0012] A plurality of partitions 7 arranged vertically at equal distances are arranged in the rake shell 1 , and each partition 7 is welded to the rake shell 1 . A water supply pipe 2 connected to a high-pressure water gun, that is, a high-pressure water supply device, is provided outside the rake shell 1 .

[0013] The above-mentioned rake shell 1 is in the shape of a square truss, the side panels are surrounded by four trapezoidal plates, and the rear cover 4 is located at the small end of the prism. The water supply pipe 2 with the water pipe connector 3 is T-shaped, the front part is welded and fixed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com