Method for preparing self-supporting graphite porous amorphous carbon thin film

An amorphous carbon, self-supporting technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problem of inability to obtain self-supporting amorphous carbon film, high ambient temperature, and inability to obtain porous structure carbon film And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

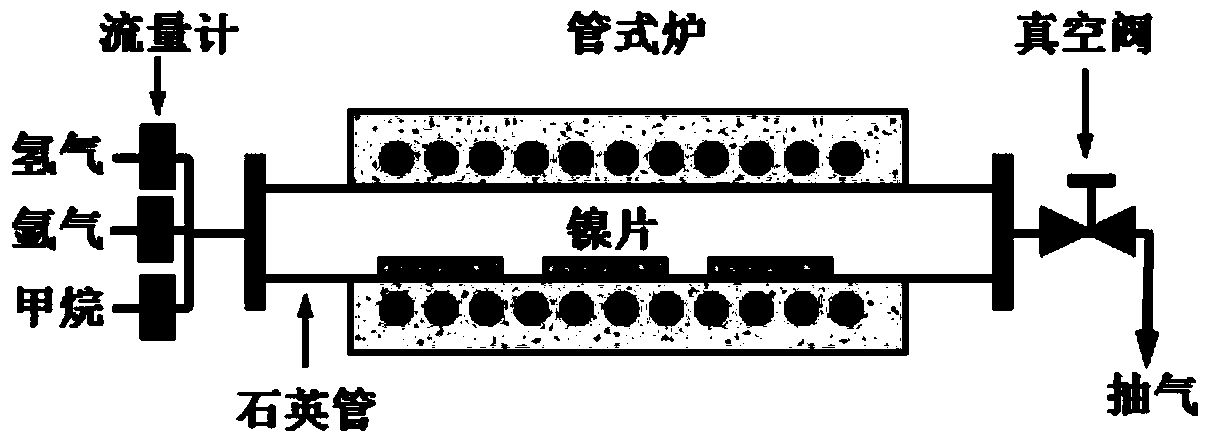

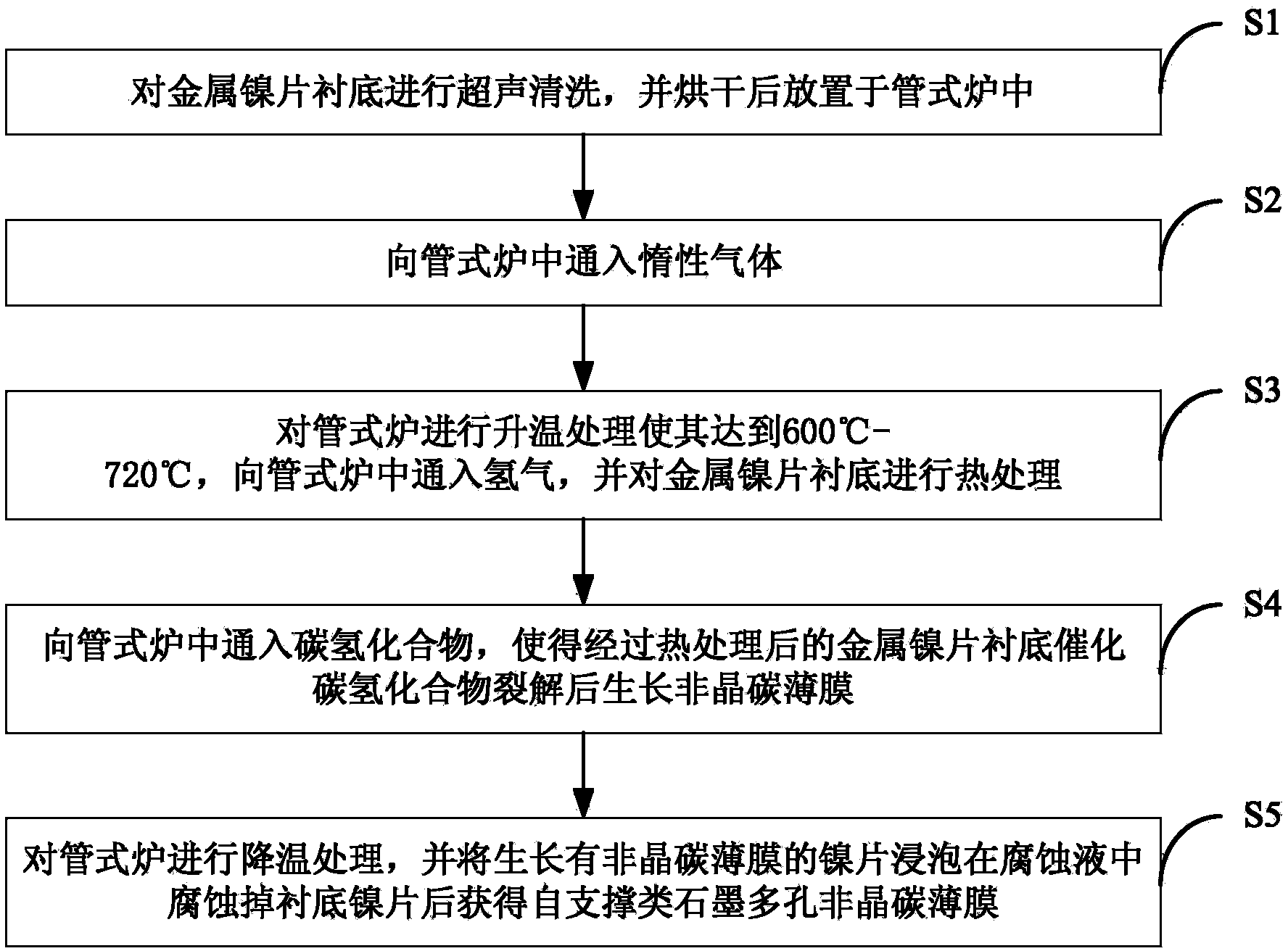

Method used

Image

Examples

preparation example Construction

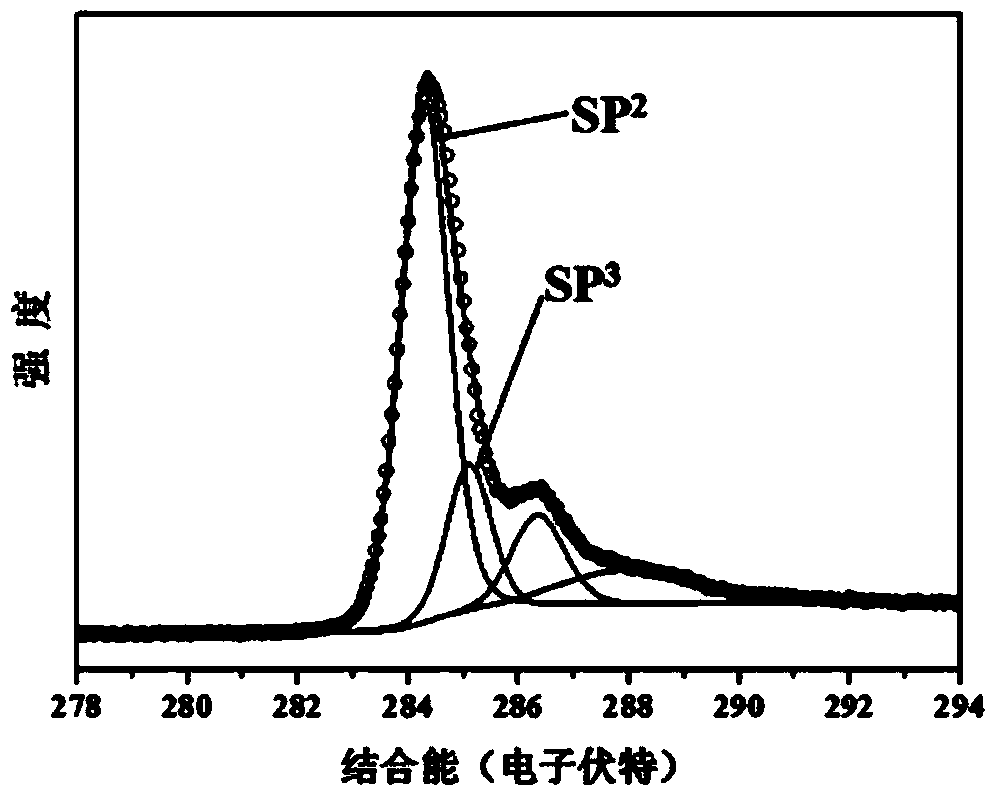

[0026] The amorphous carbon film prepared by the preparation method of the amorphous carbon film with graphite-like structure provided by the present invention has the characteristics of self-supporting, transparent and porous structure, and the thickness can be controlled from tens of nanometers to hundreds of nanometers. This provides a new way for the preparation of amorphous carbon thin films. The method includes: cleaning the substrate metal nickel sheet, heating the nickel sheet by feeding hydrogen gas at a temperature not lower than 600°C in a tube furnace, feeding hydrocarbon gas at a temperature not lower than 600°C for growth, Cool down and etch the nickel sheet with ferric chloride solution to form an amorphous carbon film. Compared with the current technology of amorphous carbon film preparation, the present invention has the following advantages: (1) simple equipment and low cost; (2) simple operation and fast preparation process; (3) self-supporting amorphous car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com