Production method of polyacrylamide modified water absorbent resin concrete internal curing agent

A technology of polyacrylamide and water-absorbent resin, applied in the field of concrete additives, can solve the problems of troublesome concrete maintenance, difficult access, concrete deformation and cracking, etc., and achieve the effects of reducing migration gradient, simple operation and obvious maintenance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

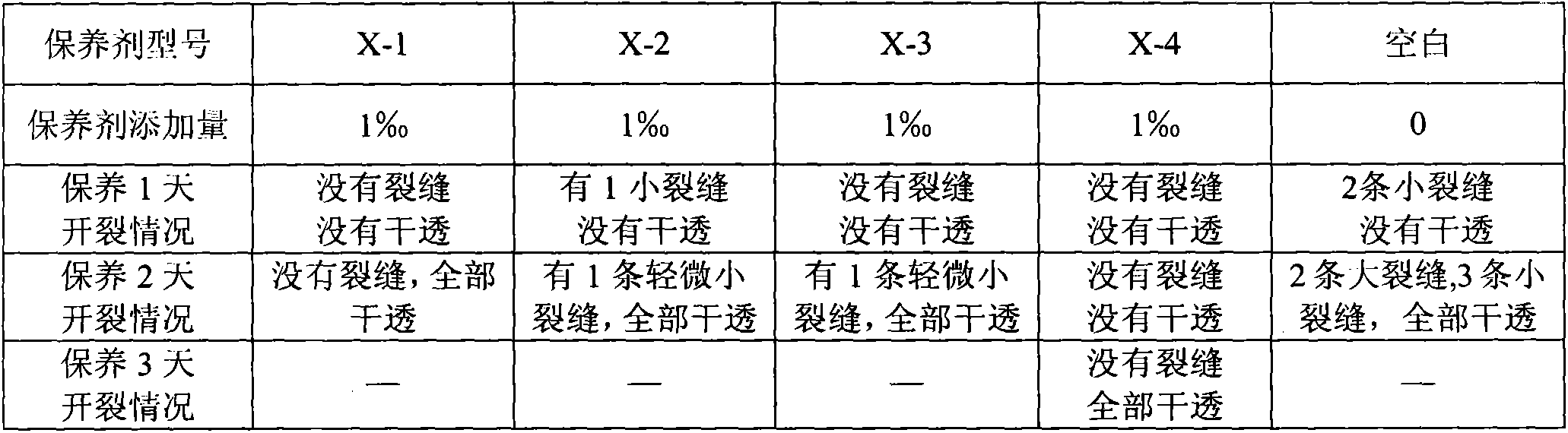

Examples

Embodiment 1

[0038] In this embodiment, the weight percentage of each monomer and water is: AM: MBA: sodium propylene sulfonate: acrylic acid: water = 20:5:20:10:45.

[0039] Solution preparation: Add 450g of distilled water to a 2000ml beaker, add 200g of AM monomer, 50g of MBA monomer, add 200g of sodium propylene sulfonate monomer, add 100g of acrylic acid monomer, stir and dissolve for 30 minutes, and slowly add in And agent (sodium hydroxide) to pH6.5±0.5. The stirring solution was continued to ripen for 30 minutes.

[0040] Solution adjustment: according to the pH range after aging, use sodium hydroxide (pH alkaline regulator) or phosphoric acid (pH acidic regulator) to adjust the pH value to 6.5±0.5 again, and adjust the temperature to 10±1°C.

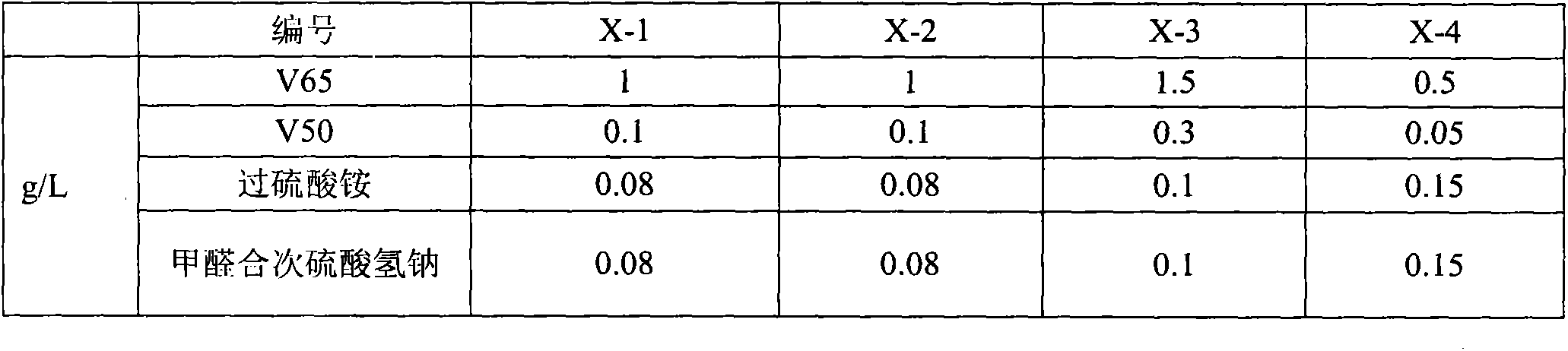

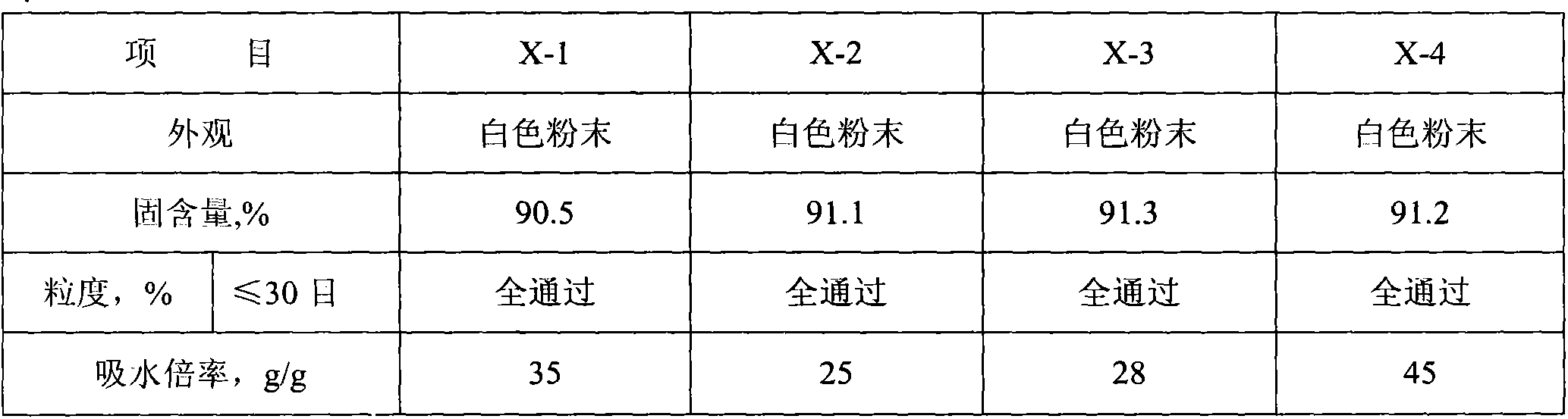

[0041] Polymerization of the solution: Blowing nitrogen to remove oxygen for 15-20 minutes, under the protection of nitrogen, add catalysts V651g / L, V500.1g / L, ammonium persulfate 0.08g / L, sodium formaldehyde sulfoxylate 0.08g / L, until Sto...

Embodiment 2

[0044] Weight percent of each monomer in water: AM: MBA: sodium propylene sulfonate: acrylic acid: water = 30:8:20:10:32.

[0045] Solution preparation: Add 320g of distilled water to a 2000ml beaker, add 300g of AM monomer, 80g of MBA monomer, add 200g of sodium propylene sulfonate monomer, add 100g of acrylic acid monomer, stir and dissolve for 30 minutes, slowly add in And agent (sodium hydroxide) to pH6.5±0.5. The stirring solution was continued to ripen for 30 minutes.

[0046] Solution adjustment: according to the pH range after aging, use sodium hydroxide (pH alkaline regulator) or phosphoric acid (pH acidic regulator) to adjust the pH value to 6.5±0.5 again, and adjust the temperature to 10±1°C.

[0047] Polymerization of the solution: Blow nitrogen to deoxygenate for 15-20 minutes, add catalyst V65lg / L, V500.1g / L, ammonium persulfate 0.08g / L, sodium formaldehyde sulfoxylate 0.08g / L sequentially under nitrogen protection, stop Blow nitrogen and open the UV lamp tube ...

Embodiment 3

[0050] Weight percent of each monomer in water: AM: MBA: sodium propylene sulfonate: acrylic acid: water = 30:8:10:5:47.

[0051] Preparation of the solution: Add 470g of distilled water to a 2000ml beaker, add 300g of AM monomer, 80g of MBA monomer, add 100g of sodium propylene sulfonate monomer, add 50g of acrylic acid monomer, stir and dissolve for 30 minutes, and slowly add in And agent (sodium hydroxide) to pH6.5±0.5. The stirring solution was continued to ripen for 30 minutes.

[0052] Solution adjustment: according to the pH range after aging, use sodium hydroxide (pH alkaline regulator) or phosphoric acid (pH acidic regulator) to adjust the pH value to 6.5±0.5 again, and adjust the temperature to 10±1°C.

[0053] Polymerization of the solution: Blow nitrogen to remove oxygen for 15-20 minutes, add catalyst V651.5g / L, V500.3g / L, ammonium persulfate 0.1g / L, sodium formaldehyde sulfoxylate 0.1g / L in sequence under nitrogen protection , stop blowing nitrogen and turn on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com