Slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, preparation method and application thereof

A technology of SAPO-34 and molecular sieve, which is applied in the field of molecular sieves, can solve the problems of uncontrollable low-silicon SAPO-34 molecular sieve synthesis and troubles, and achieve the effects of reducing carbon deposition, increasing diffusion rate, and prolonging catalytic life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

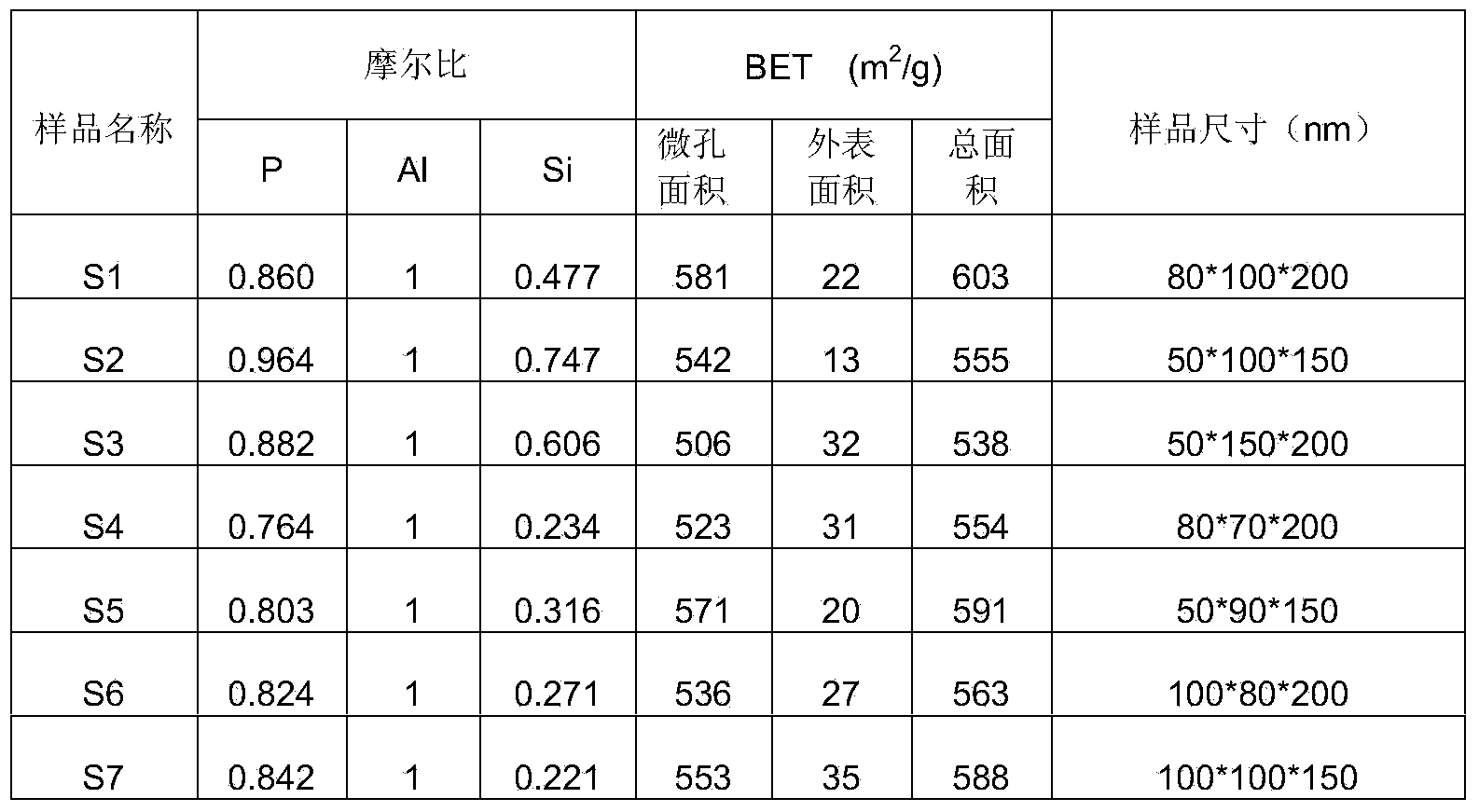

Embodiment 1

[0041] Mix aluminum isopropoxide, water, and tetraethylammonium hydroxide thoroughly and then treat at 25°C for 2 hours to obtain a mixture; add silica sol and phosphoric acid to the above mixture in situ, and continue stirring for 5 hours to obtain SAPO-34 Molecular sieve initial gel mixture; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 1.0TEAOH:0.3SiO 2 : 1.2P 2 o 5 : 1.0Al 2 o 3 : 42.8H 2 O; put the initial gel mixture into a stainless steel reaction kettle with polytetrafluoroethylene lining, then put the reaction kettle in an oven, heat up to 170°C, and carry out constant temperature (170°C) under hydrothermal conditions under autogenous pressure ) crystallized for three days. Then, the solid product was separated by centrifugation, washed repeatedly with deionized water until neutral, and dried in the air at 75°C to obtain the original SAPO-34 molecular sieve powder, which was ...

Embodiment 2

[0043] Boehmite, water, and tetraethylammonium hydroxide were thoroughly mixed and stirred and treated at 25°C for 1 hour to obtain a mixture; white carbon black and phosphoric acid were added to the above mixture in situ, and the stirring was continued for 7 hours to obtain SAPO- 34 molecular sieve initial gel mixture; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 2.0TEAOH: 0.9SiO 2 : 2.0P 2 o 5 : 1.0Al 2 o 3 : 200.0H 2 O; put the initial gel mixture into a stainless steel reaction kettle with polytetrafluoroethylene lining, then put the reaction kettle in an oven, heat up to 200 °C, and carry out constant temperature (200 °C) under hydrothermal conditions under autogenous pressure ) crystallized for 7 days. Then, the solid product was separated by centrifugation, washed repeatedly with deionized water until neutral, and dried in the air at 75°C to obtain the original SAPO-34 molecul...

Embodiment 3

[0045] Mix Al2O3, water, and tetraethylammonium hydroxide thoroughly and then treat it at 25°C for 4 hours to obtain a mixture; add silica sol and phosphoric acid to the above mixture in situ, and continue stirring for 2 hours to obtain SAPO-34 Molecular sieve initial gel mixture; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 1TEAOH: 0.7SiO 2 : 1.5P 2 o 5 : 1.0Al 2 o 3 : 140H 2 O; put the initial gel mixture into a stainless steel reaction kettle with polytetrafluoroethylene lining, then put the reaction kettle in an oven, heat up to 150°C, and carry out constant temperature (150°C) under hydrothermal conditions under autogenous pressure ) crystallized for 1 day. Then, the solid product was separated by centrifugation, washed repeatedly with deionized water until neutral, and dried in the air at 75°C to obtain the original SAPO-34 molecular sieve powder, which was roasted at 600°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com