Rapid assembling and disassembling universal clamp for right angle surface planning processing

A fast and fixture technology, applied in wood processing equipment, processing machines for manufacturing flat surfaces, manufacturing tools, etc., can solve the problems of low production efficiency, short supply, low step processing efficiency, etc., and achieve strong adaptability and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

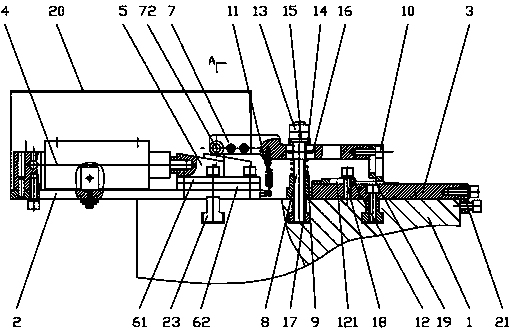

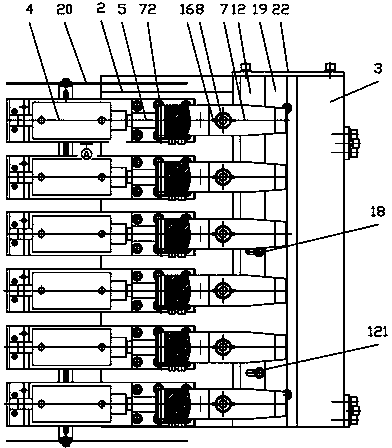

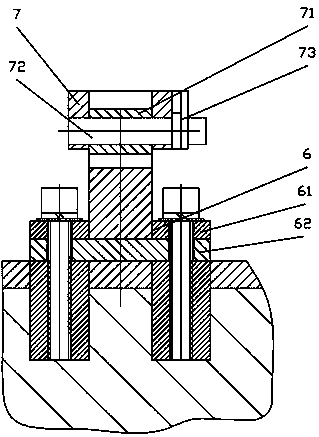

[0019] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention is further described,

[0020] Such as Figures 1 to 3 As shown, the present invention provides a universal jig for fast loading and unloading of rectangular surface planing, including a base plate 2 and a backing plate 3 arranged on a workbench 1, a driving device is provided on the bottom plate 2, and a positioning device is provided on the backing plate 3. Also includes a clamping device located between the driving device and the positioning device, wherein the driving device includes a cylinder 4, the cylinder 4 is fixed on the base plate 2, the driven end of the cylinder 4 is fixedly connected with a wedge 5, the wedge 5 and The guide groove 6 fixed on the bottom plate 2 is slidingly connected; the clamping device includes a pressure plate 7, a support rod 8, one end of the support rod 8 is socketed with the middle part of the pressure plate 7, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com