Bearing metallographic analysis grinding machine

A metallographic analysis and grinding machine technology, which is applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve problems such as low efficiency, personal injury, and low quality assurance of ground products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

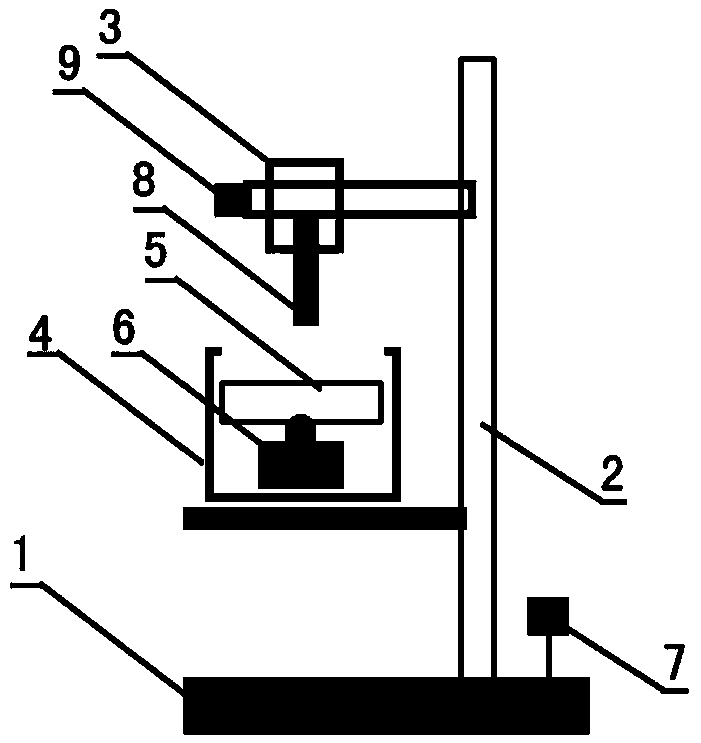

[0012] Embodiment: as shown in the accompanying drawing. Bearing metallographic analysis grinding machine, including a frame 1, telescopic track 2 is set on the frame, metallographic piece fixing device 3 is set on the telescopic track 2; grinding table 4 is set, including grinding wheel 5, motor 6, control device 7, During grinding, the metallographic piece 7 is fixed on the metallographic piece fixing device 3, and the grinding parameters are set in the control device 7 to perform corresponding metallographic analysis and grinding.

[0013] Bearing metallographic analysis grinding machine, the metallographic piece fixing device 3 fixes the metallographic piece 8 in the form of a clamp.

[0014] Bearing metallographic analysis grinding machine, the fixture adopts the spiral method to fix the metallographic parts.

[0015] The bearing metallographic analysis grinding machine is equipped with a prompting device 9 to properly prompt the grinding progress.

[0016] Bearing meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com