Oil hole drilling tool

A technology of oil hole and tooling, which is applied in the field of tooling and fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

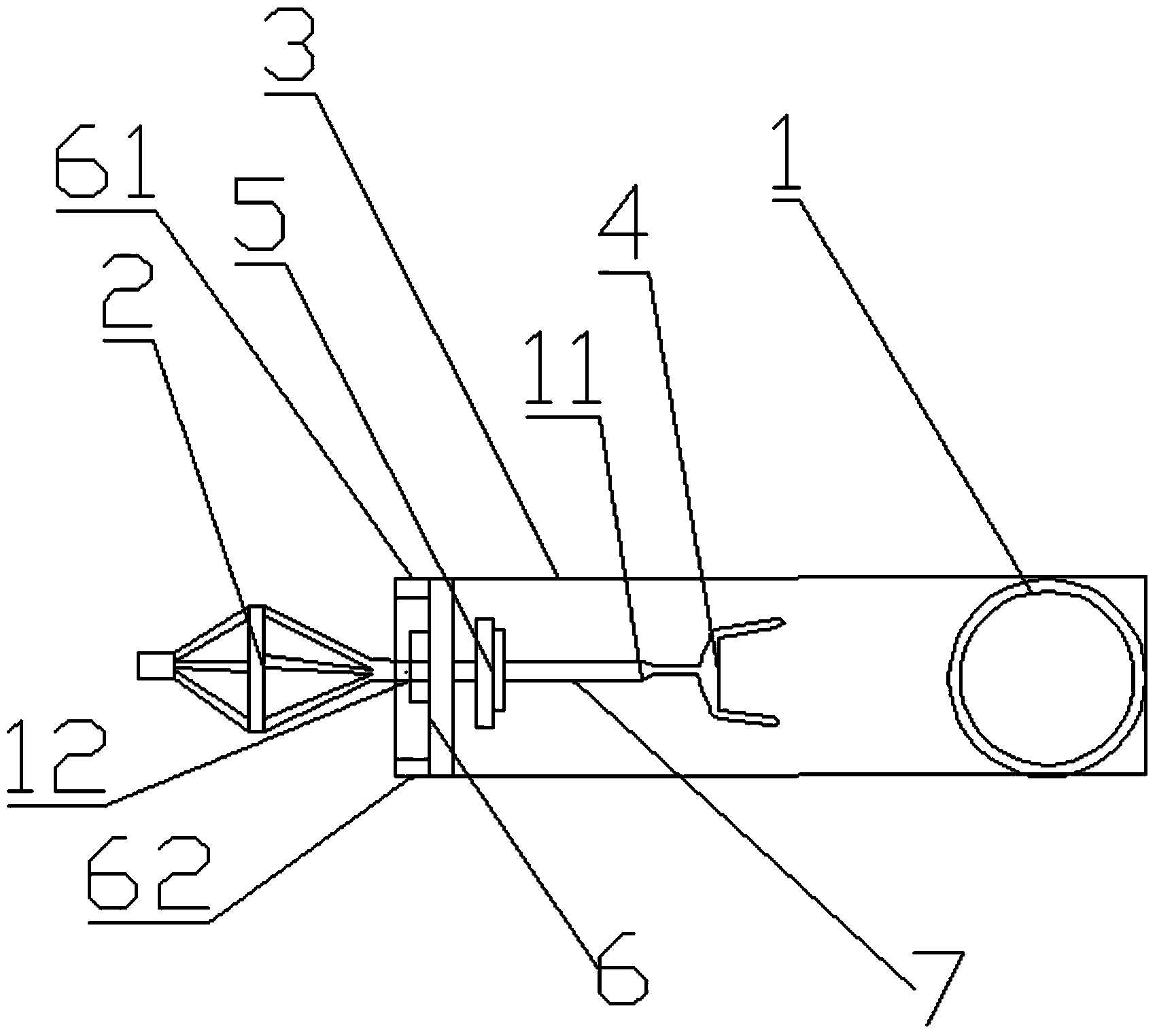

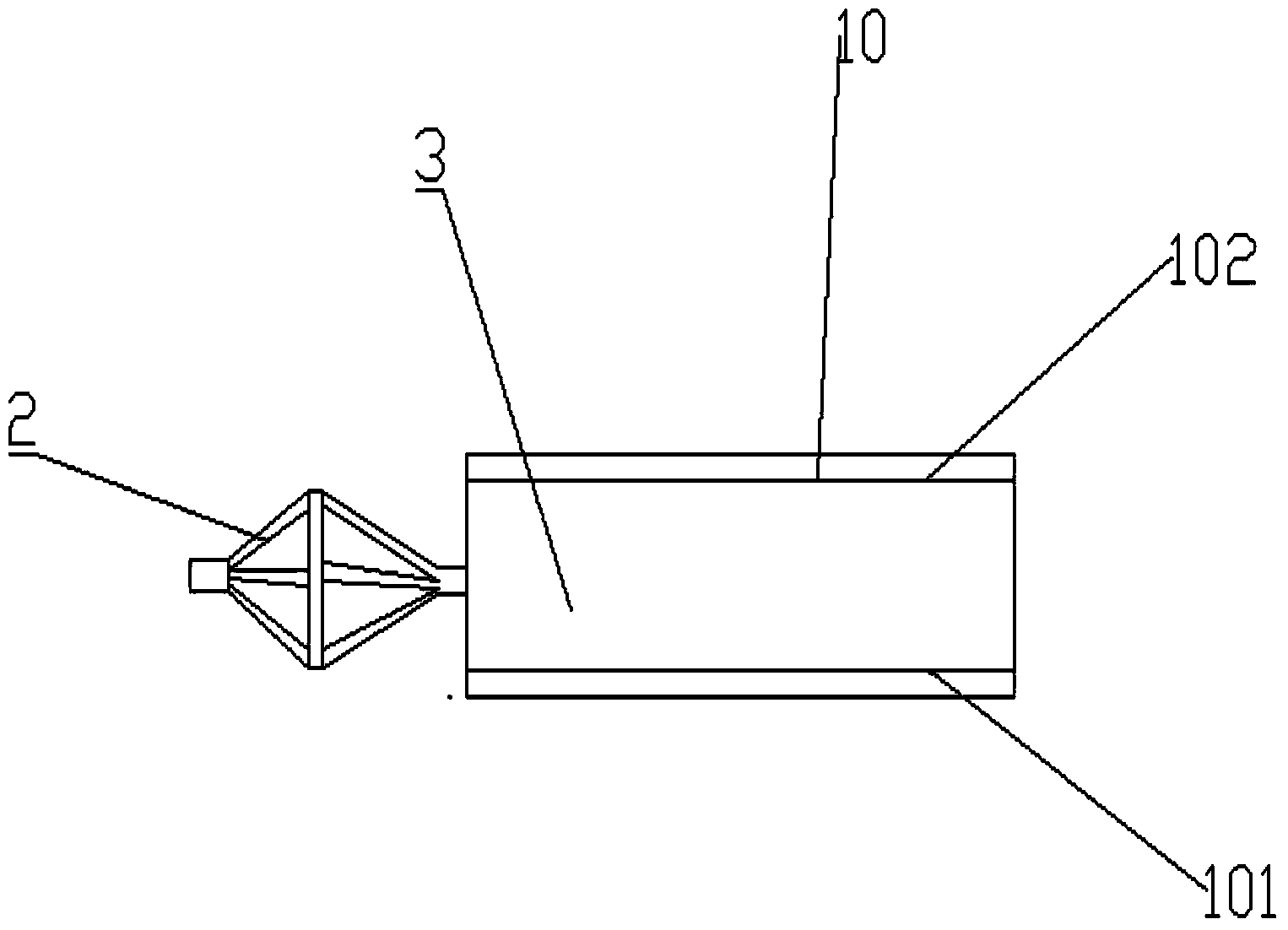

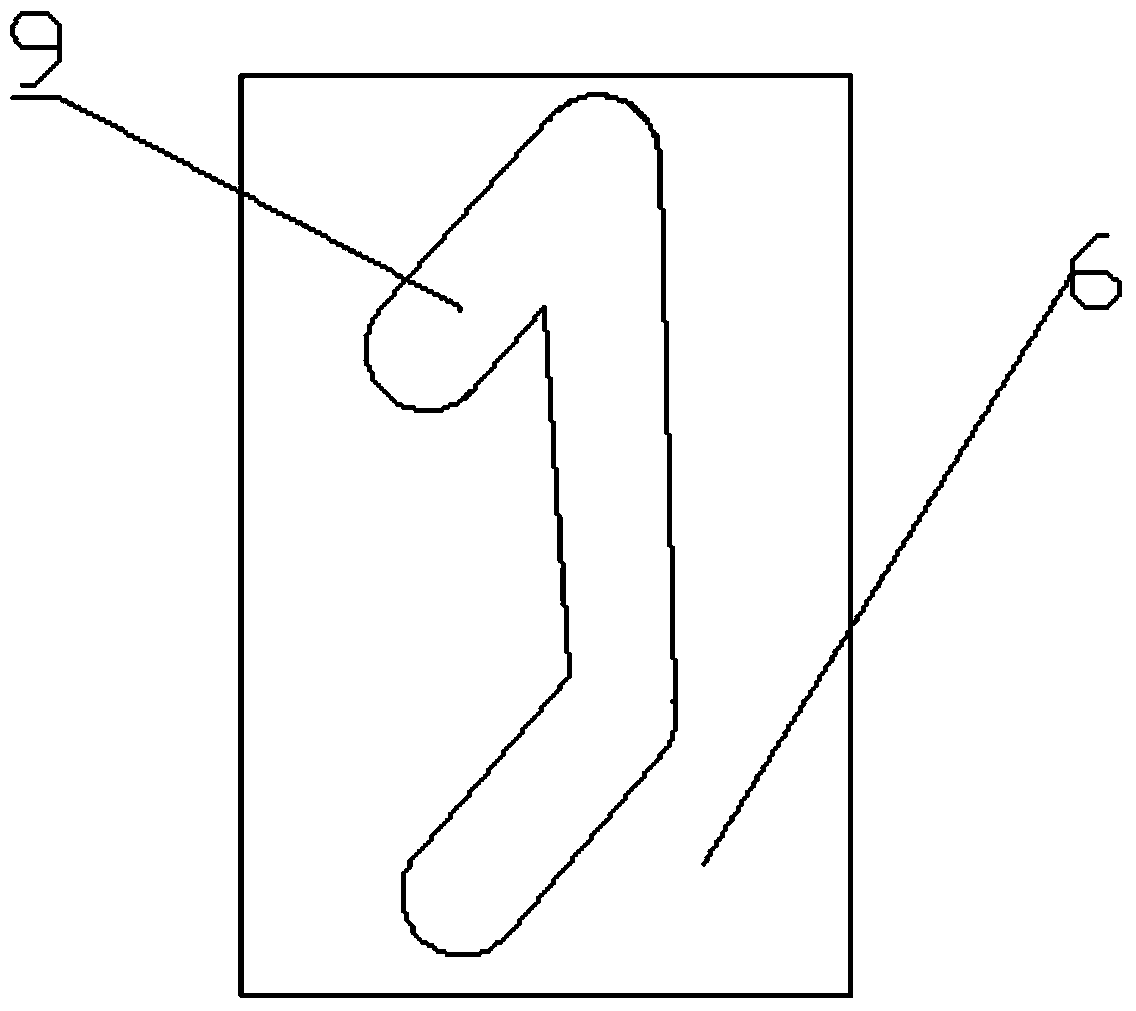

[0028] A tool for drilling oil holes, comprising a turret (11), a tool body (16), and a cylinder (1); the turret (11) includes a handle (2), a rotating rod (7), and a pistol holder (4); The handle (2) is fixedly connected to the rotating rod (7); the rotating rod (7) is connected to the pistol frame (4); the pistol frame (4) can rotate; the main body of the tooling (16) includes a bottom bracket (3) and a support plate (6); Bottom support (3) comprises base plate (10), left support plate (101), right support plate (101); Left support plate (101), right support plate (101) length is greater than base plate (10) length; Base plate (10) There is a cylinder (1) on the front; the cylinder (1) is at the tail of one end of the base plate (10); the left support plate (101) is fixed on the left edge of the back of the base plate (10); the right support plate (101) is fixed on the base plate The right edge of the back side of (10); left support plate (101), right support plate (101) one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com