Sawing wire for use in wire saw machine

A technology for sawing ropes, wire sawing machines, applied in the direction of transmission elements or pulleys with ropes or cables, mechanical equipment, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

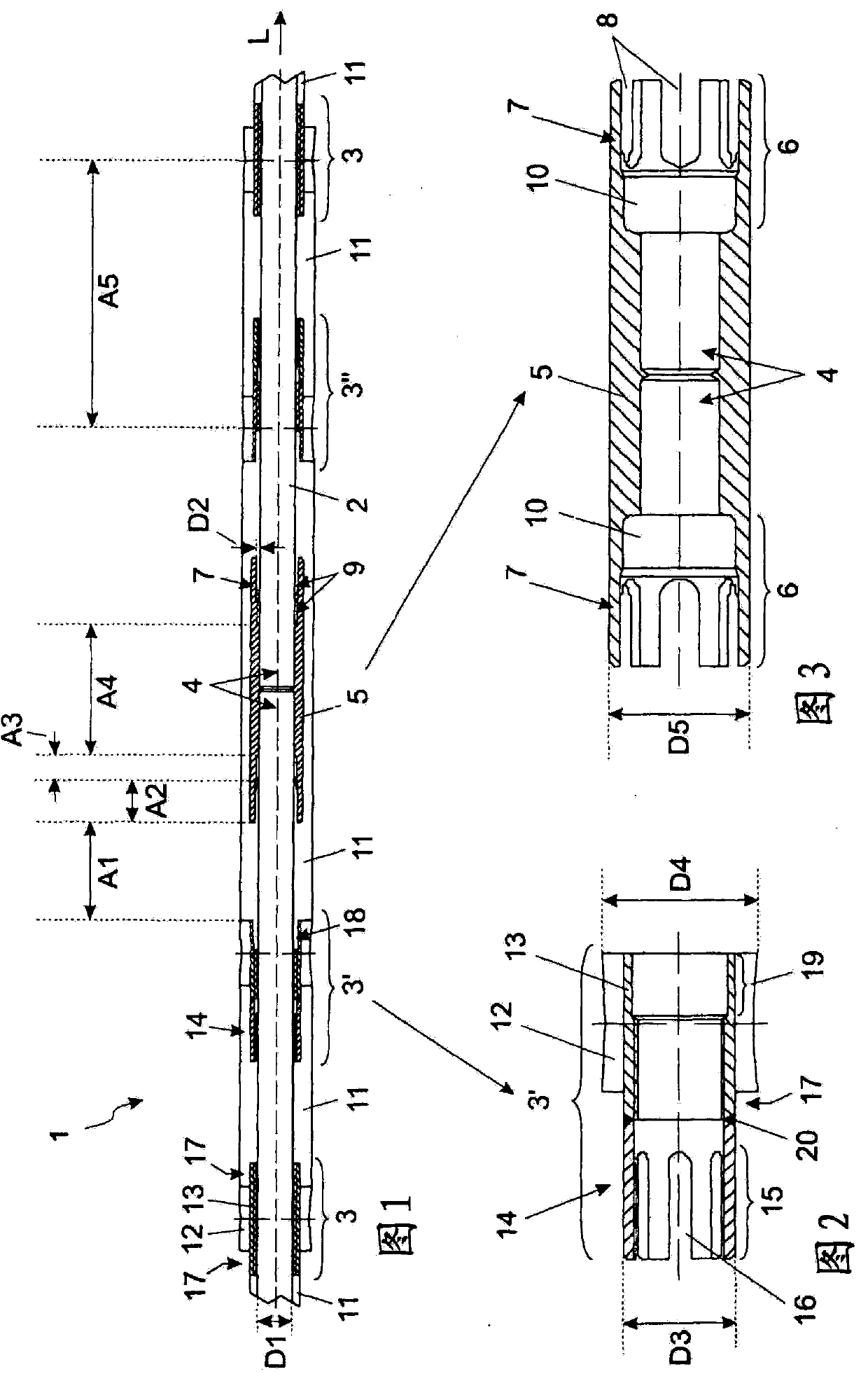

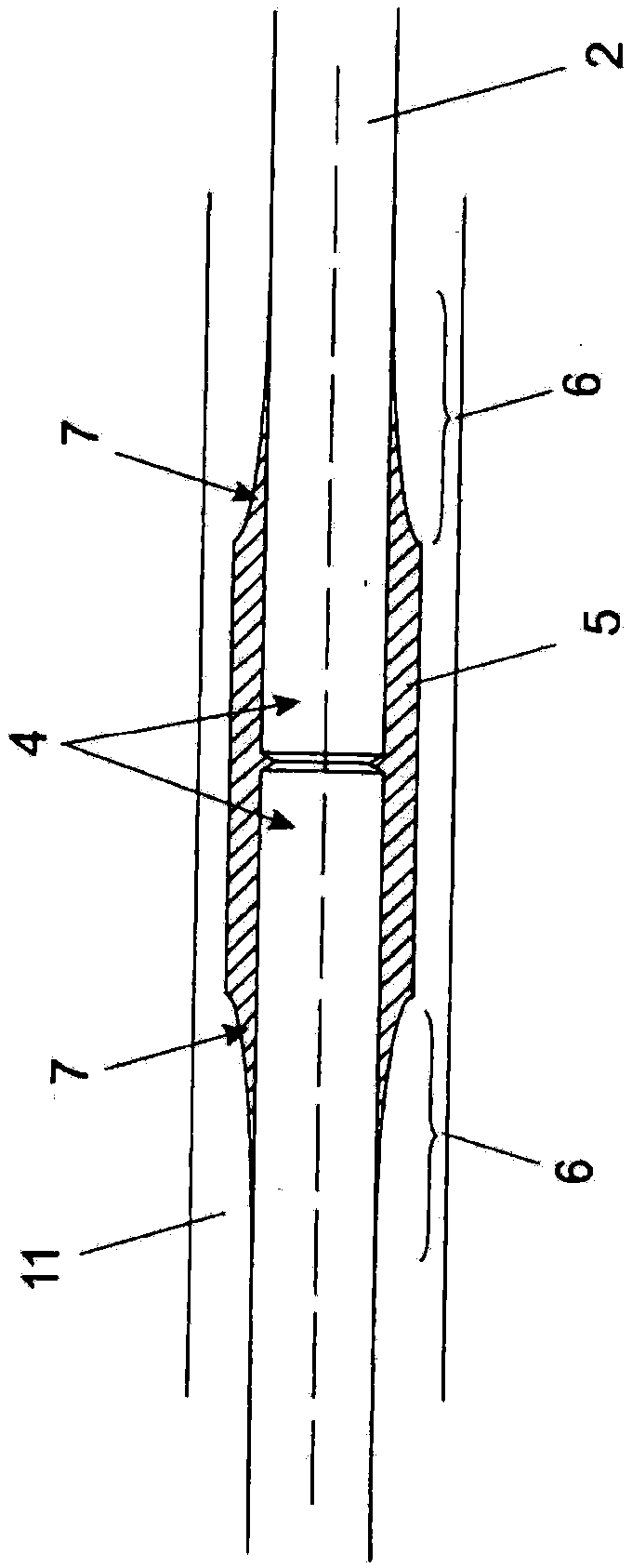

[0022] figure 1 A cross-sectional view of a section of the sawing wire 1 which is relevant for the description of the invention is shown schematically. This section can be, for example, a part of a sawing wire 1 connected to form an endless loop. Since the length of such a rope ring is usually several meters (for example, 50 meters) and figure 1 The part shown is actually only a few centimeters long, so the curvature of the sawing rope 1 cannot be seen in this figure. The partial diagram shows (viewed from the center towards the edge of the figure): a sleeve-shaped compression closure 5, by which the ends 4 of the steel wire rope 2 are connected to each other, and two sleeve-shaped compression closures 5 are connected to each other. Adjacent cutting beads 3' and 3" are structured differently from the remaining cutting beads 3, two of which are visible at the edge of the figure. All cutting beads 3, 3' and 3" are arranged on the wire rope 2. The sleeve-like compression closu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com