Electric motor and motor/gear unit and variable-length drive means having such an electric motor

A technology of electric motors and planetary gears, applied in electromechanical devices, electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

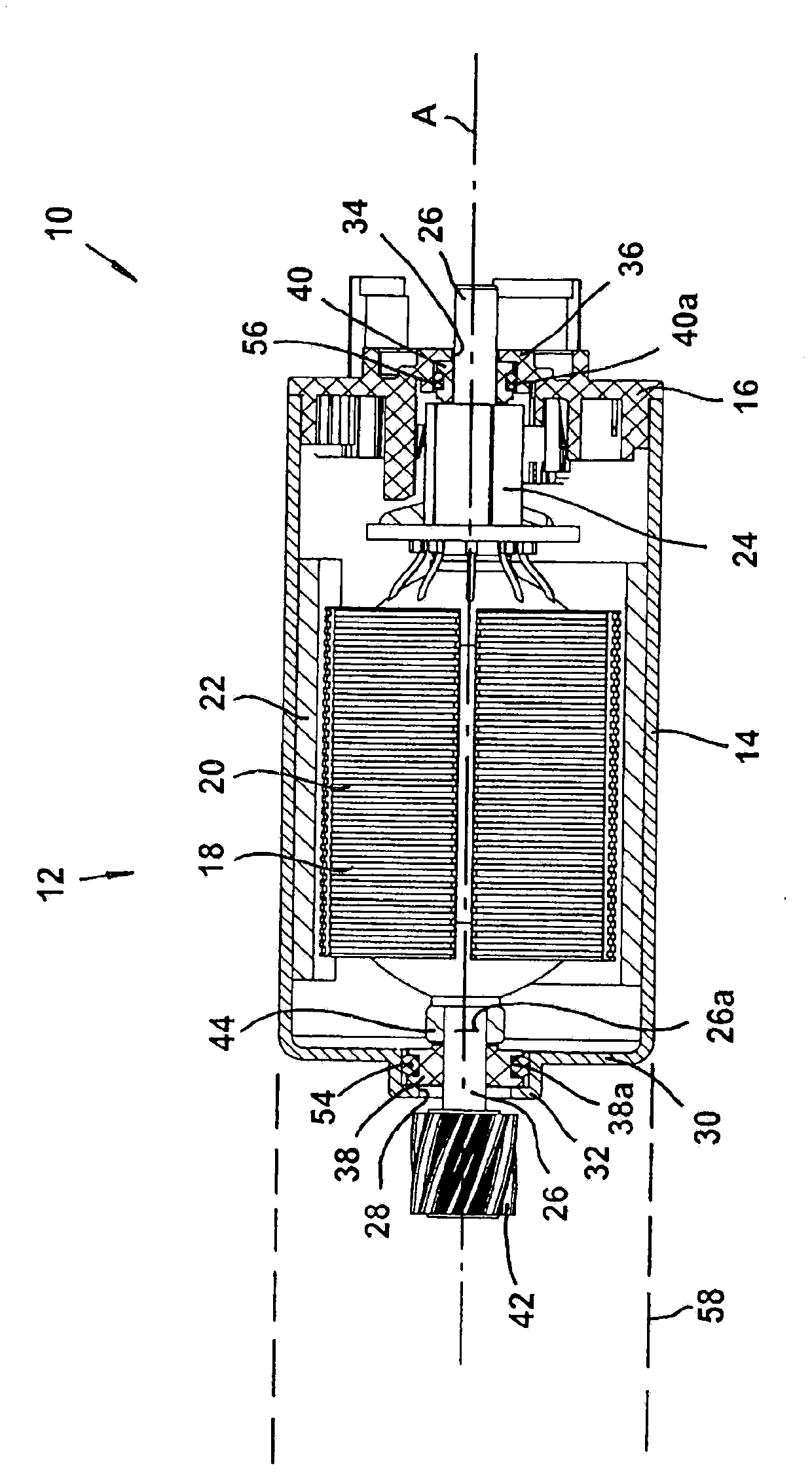

[0023] figure 1 A longitudinal section of a first embodiment of an electric motor 10 according to the invention is shown. The electric motor 10 includes a housing 12 formed from a cup part 14 and a cover part 16 . A rotor 18 is received in the housing 12 . The rotor windings 20 of the rotor 18 cooperate in a manner known per se with permanent stator magnets 22 to rotate the rotor 18 relative to the housing 12 when a direct current is supplied in an alternating manner through a commutator 24 . The rotor shaft 26 of the rotor 18 is by means of its figure 1 The left end seen in is guided to the outside of the housing 12 through an opening 28 formed in the wall 30 of the cup-shaped part 14, or rather in a recess 32 of this wall 30, wherein the wall 30 extends at right angles to the axis A of the rotor shaft 26 . Similarly, the rotor shaft 26 at figure 1 The right end, seen in , is guided to the outside of the housing 12 through an opening 34 in a recess 36 of the cover par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com