A simply supported beam dynamic vibration absorber with adjustable frequency

A dynamic vibration absorber and simply supported beam technology, applied in the field of vibration absorbers, can solve the problems of inconvenient practical application and inability to provide natural frequencies, and achieve the effect of less electromagnetic leakage and reduced demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

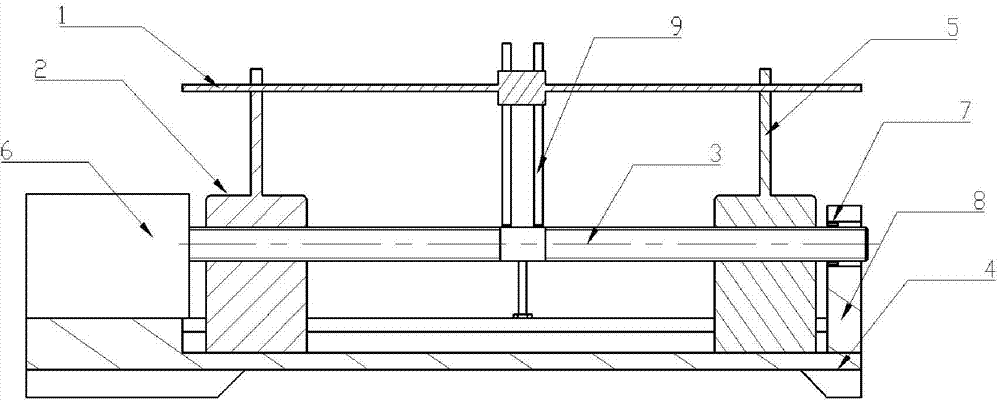

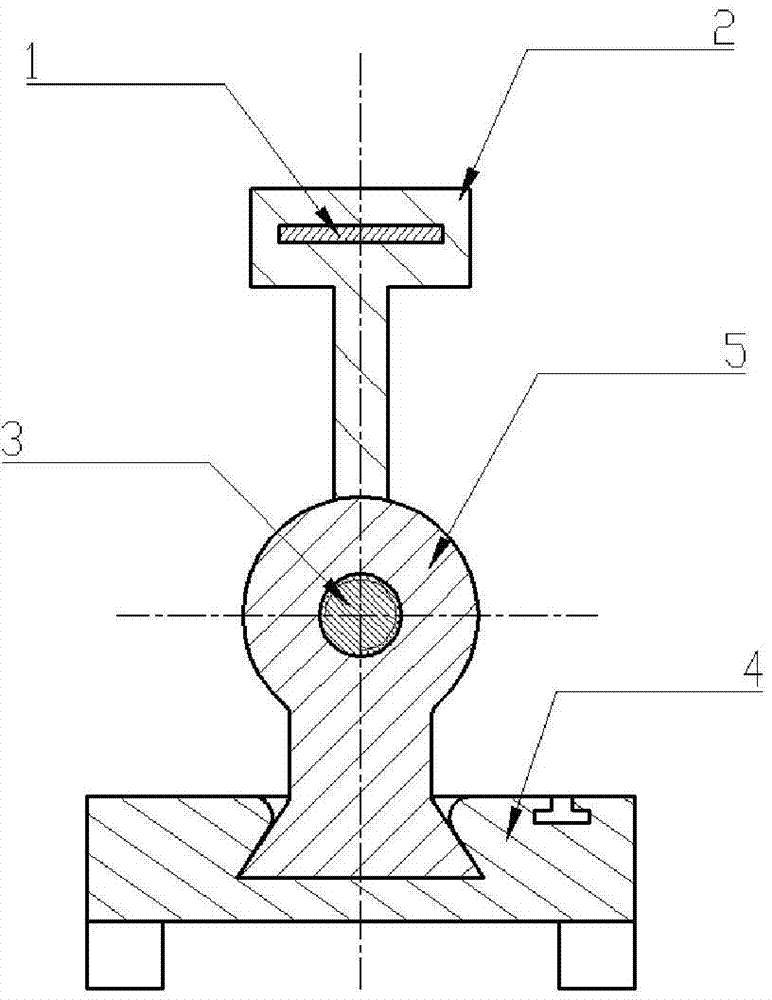

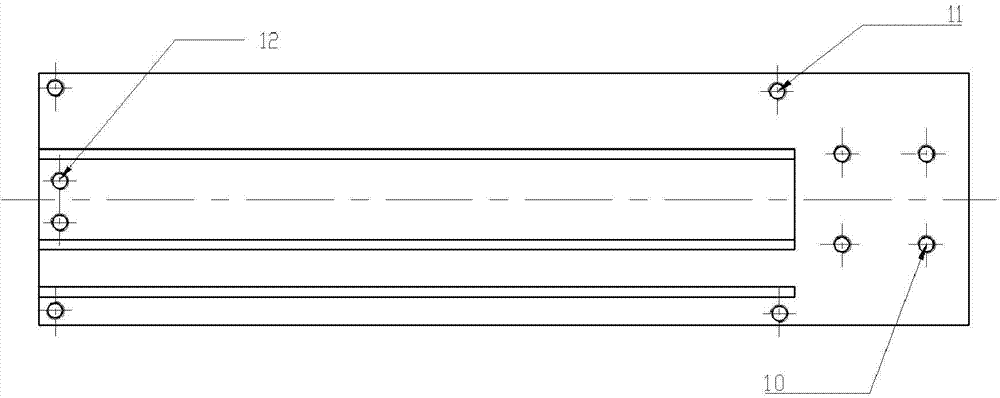

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1~3 , the base 4 is the basic base, which is used to install and fix various other components. The vibration-absorbing body is a metal beam 1 structure with simple support at both ends and adjustable working length. The material of the metal beam 1 structure is spring steel. In the length direction of the base 4, there is a dovetail groove in the center, which is used as a guide rail for installing the slider 2, and restricts the movement of the slider 2 in other directions so that it can only move along one degree of freedom. One side of the dovetail groove There are inverted T-shaped grooves in the same direction in processing, which are used to install the limiter 9. Base 4 is fixedly installed with a support plate 8 with bolt at the other end of placing motor, has hole on the support plate, cooperates with self-aligning bearing 7. Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com