Preparation method of dry powder phosphogypsum base cementing material

A technology of composite cementitious materials and phosphogypsum, which is applied in the field of preparation of dry powdered phosphogypsum-based cementitious materials, can solve problems such as insufficient strength and limited application range, and achieve the effect of improving strength performance and reducing stacking pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

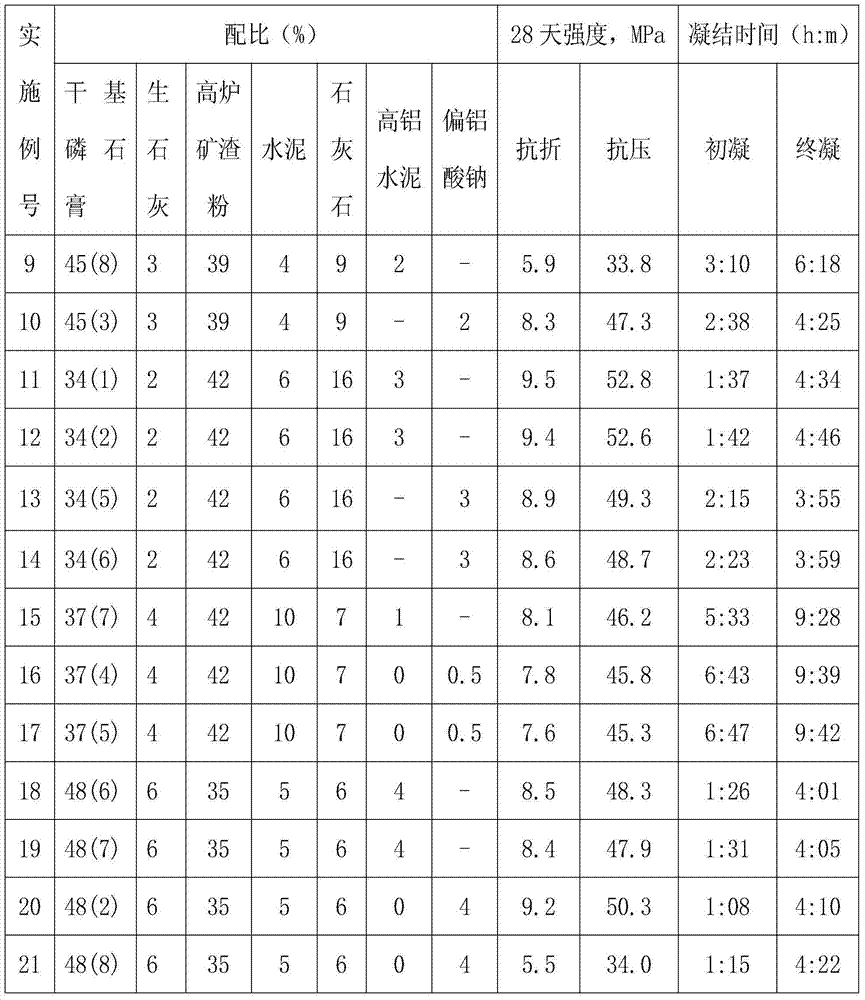

Examples

Embodiment Construction

[0015] The percentages used below are all percentages by weight.

[0016] The phosphogypsum used in the present invention is the phosphogypsum discharged by Anhui Liuguo Chemical Industry Co., Ltd. by utilizing low-grade Yichang phosphate rock to produce diammonium phosphate. The specific components are as follows:

[0017] CaO:29.22%, SO 3 :44.10%,P 2 o 5 : 1.02%, F: 1.28%, SiO 2 :2.51%,Al 2 o 3 :0.81%,Fe 2 o 3 : 1.05%, MgO: 1.37%, Na 2 O:0.36%

[0018] Each embodiment of the present invention is carried out according to the following process flow: after the wet phosphogypsum is first broken, it is neutralized and formed, and the free water is removed in a drying kiln at a low temperature (40°C-80°C) to control the free water. The water content is not more than 1%. The following table 1 is the preparation example of dry basis phosphogypsum.

[0019] Table 1 The content of hemihydrate gypsum in dry basis phosphogypsum obtained by drying at different temperatures

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com