Unpowered rollover machine

A turning machine and power technology, applied in the field of online reel turning equipment, can solve the problems of easily damaged reels, increased production costs, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

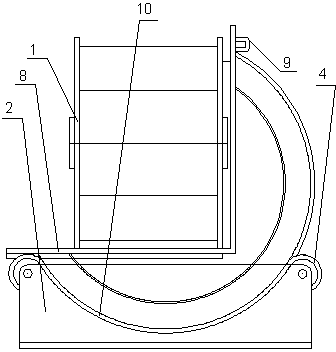

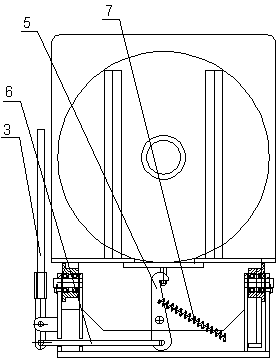

[0012] The unpowered turning machine includes a frame 2, a turning body arranged on the frame 2 and a tripping device. The frame 2 is provided with a roller 4; the turning body includes two flat plates carrying the wire reel 1. 8 and a fixed grappling hook 9 connected to the lower surface of the plate 8. The lower part of the plate 8 is provided with an arc-shaped guide rail 10, and the guide rail 10 slides on the roller 4; the trip device is arranged in the frame 2 It is movably connected with the fixed grappling hook 9 to control the movement of the turning body on the roller 4. The tripping device includes a pull rod 3, a connecting rod 6, a tension spring 7 and a movable grappling hook 5. The pull rod 3 is set on the machine On the frame 2, a connecting rod 6 is connected to the pull rod 3, and the other end of the connecting rod 6 is connected to a movable grappling hook 5. One end of the tension spring 7 is connected to the movable grapple 5, and the other end is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com