Differential mechanism coupling wheel set used for urban rail vehicle

An urban track, coupled wheelset technology, applied in the directions of wheels, vehicle parts, axles, etc., can solve the problems that the vehicle cannot be automatically recovered, cannot be automatically aligned, and reduce the speed of rotation, and achieves good guiding performance and automatic alignment performance, The effect of good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

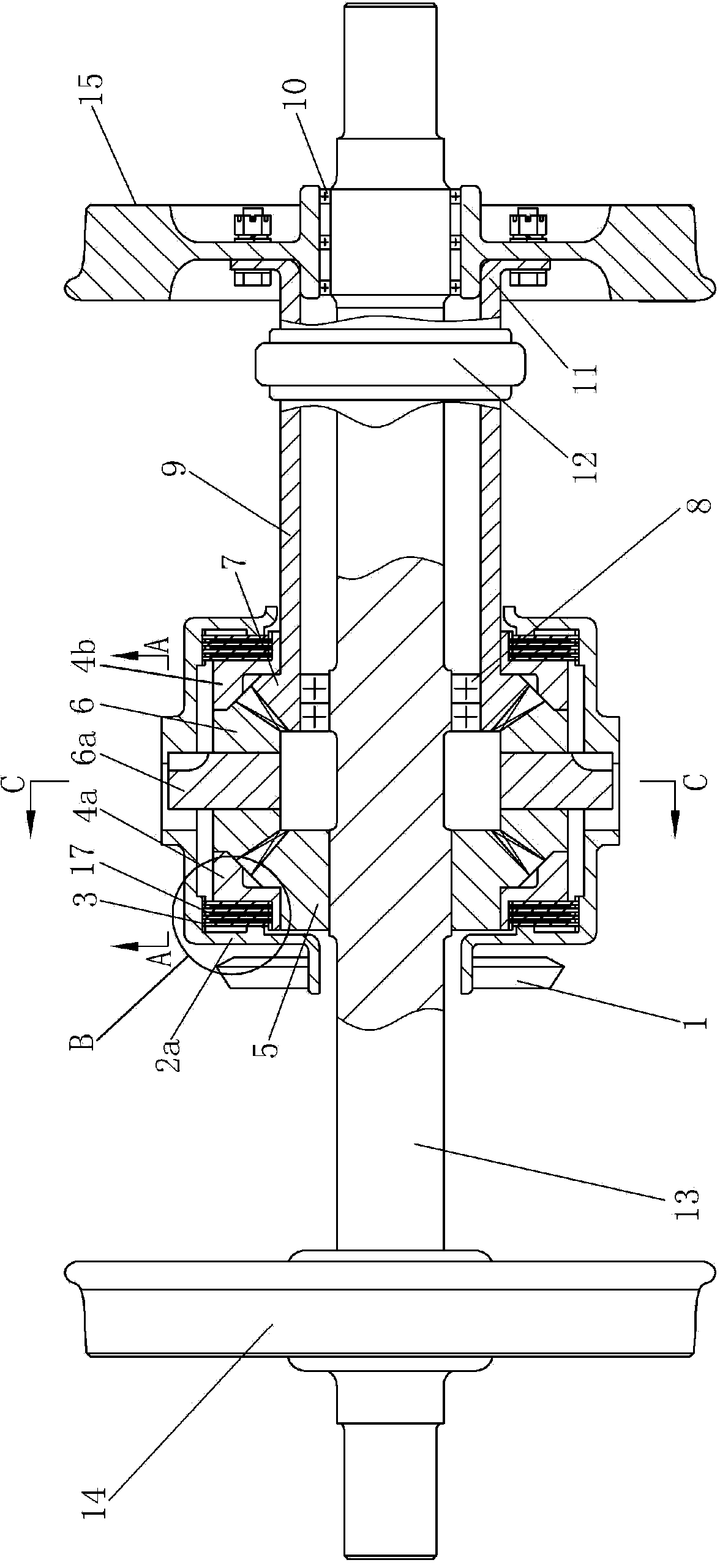

[0025] Figure 1-4 As shown, a specific embodiment of the present invention is: a differential coupling wheel set for an urban rail vehicle, including a left wheel 14 , a right wheel 15 and an axle 13 .

[0026] Left wheel 14 is fixed on the left side of axle shaft 13, and right wheel 15 is installed on the right side of axle shaft 13 by bearing 10; The specific composition of the accelerator is:

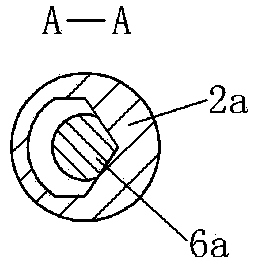

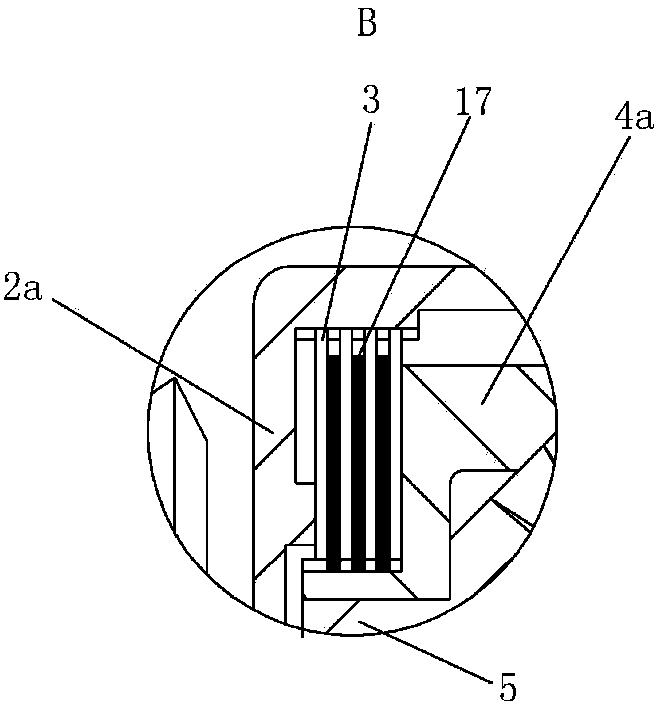

[0027] The left half-shaft sun gear 5 is fixed on the axle 13, the right half-shaft sun gear 7 is mounted on the axle 13 through the gear bearing 8, the left half-shaft sun gear 5 and the right half-shaft sun gear 7 mesh with four small planetary gears 6 ; The four planetary gears 6 are connected with the planetary shaft 6a through bearings; one side of the end section of the planetary shaft 6a is ">" shaped, and cooperates with the planetary shaft groove on the casing 2a, and the " >" shape direction is opposite; the driving gear 1 connected with the drive motor is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com