Plastic eyeglass capable of improving eccentricity and manufacturing method thereof

A technology of plastic lens and manufacturing method, which is applied in the fields of lenses, other household appliances, optics, etc., can solve the problems that the finished lens is too thick or too thin, which affects the optical properties, etc., and achieve the effect of narrowing the gap and good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

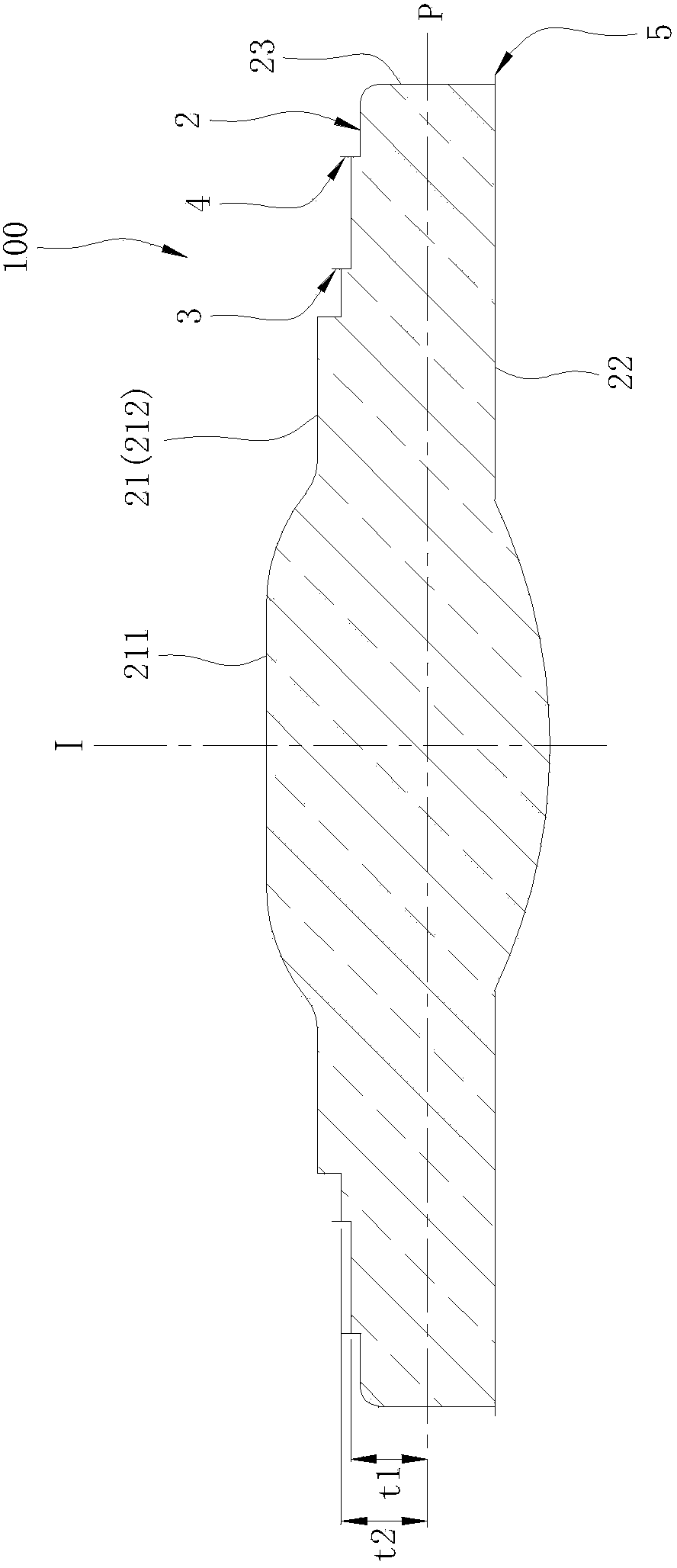

[0061] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. In addition, the drawings in the description are only used to assist in describing the various technologies of this case, and the ratios of the length, width, thickness and related dimensions of the mold and lens are not limited thereto.

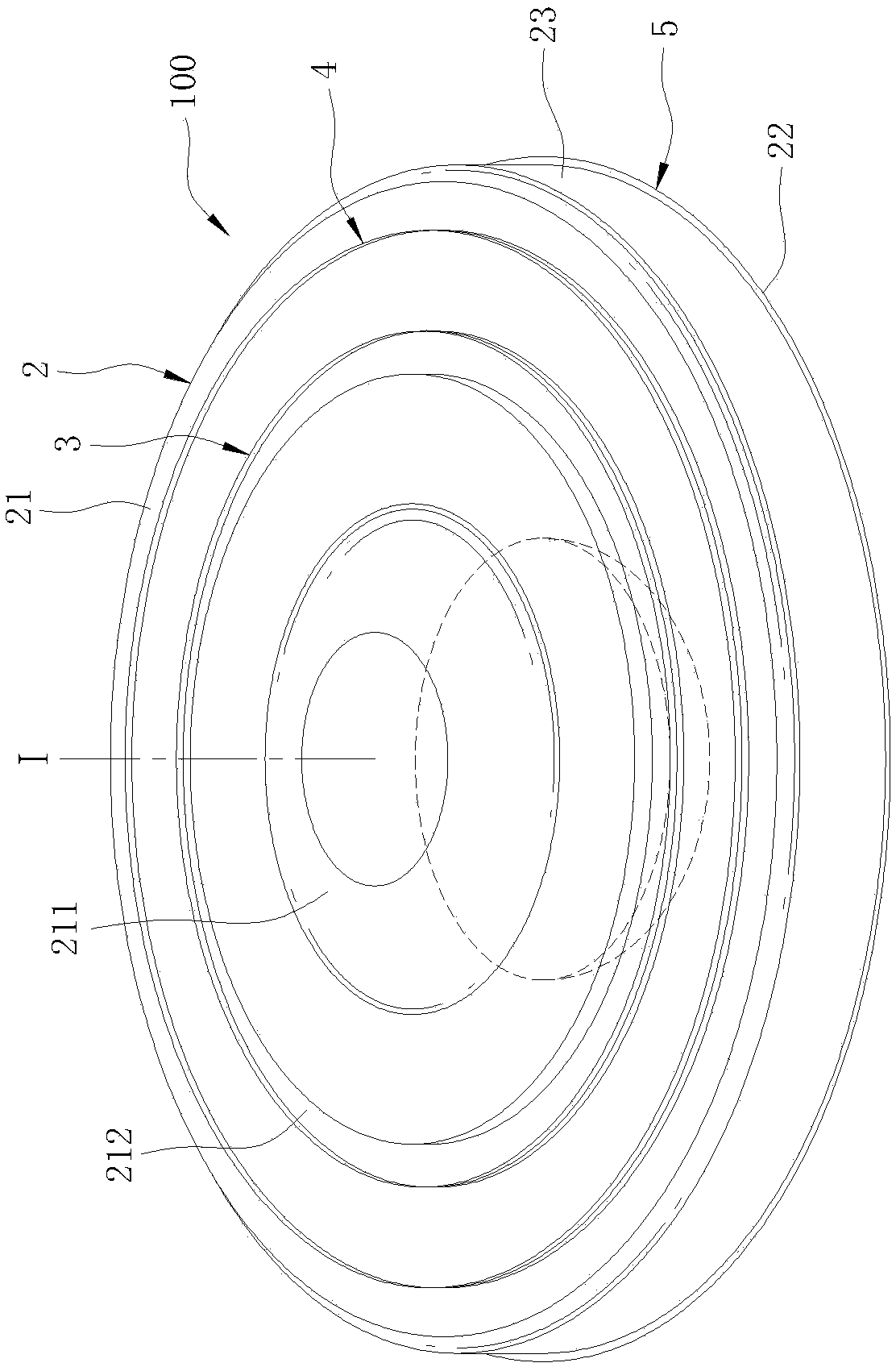

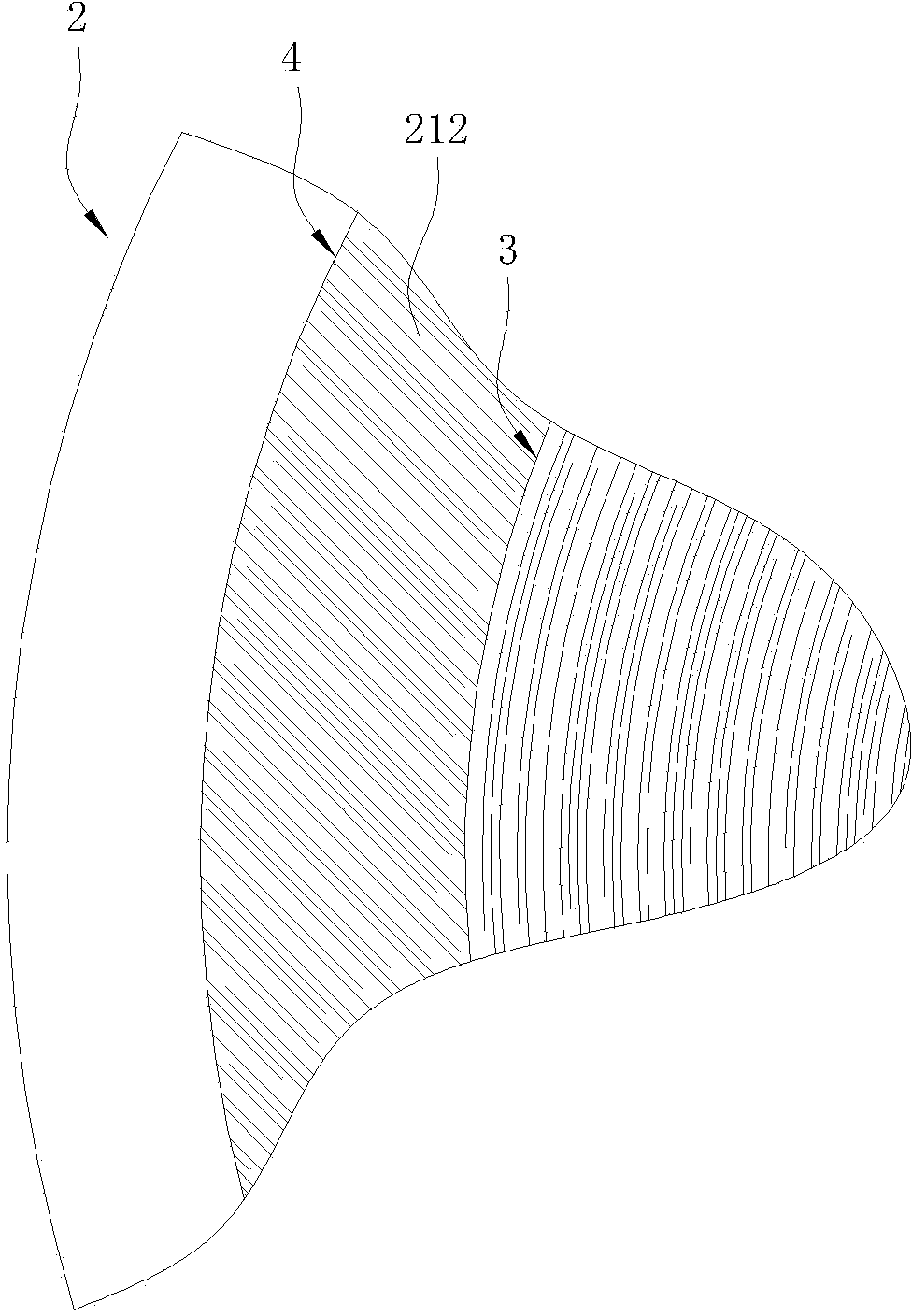

[0062] refer to figure 1 and figure 2 , A preferred embodiment of the plastic lens that can improve the decentration of the present invention includes a main body 2 , a first burr 3 , a second burr 4 , and a third burr 5 .

[0063] The main body 2 includes a first surface 21 and a second surface 22 arranged at intervals along an optical axis I and respectively arranged on both sides of the main body 2, and a peripheral edge connected to the first surface 21 and the second surface 22. Between and around the circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com