Clamping and positioning device used for disassembling and assembling airplane pneumatic starter rotor and rotor disassembling and assembling method

A technology of clamping positioning and starting motor, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., to achieve the effects of easy disassembly and maintenance, solid quality, and easy modification and upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

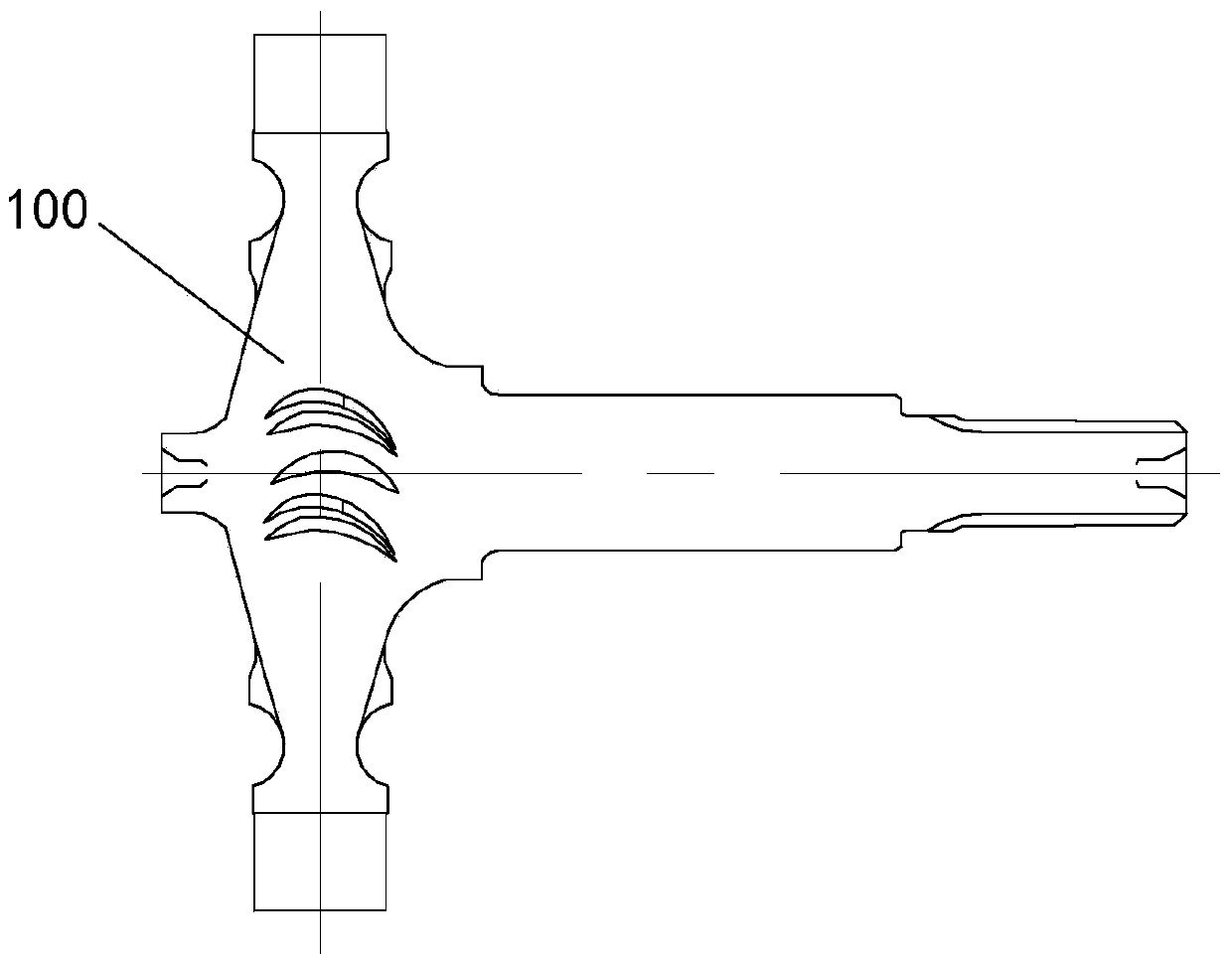

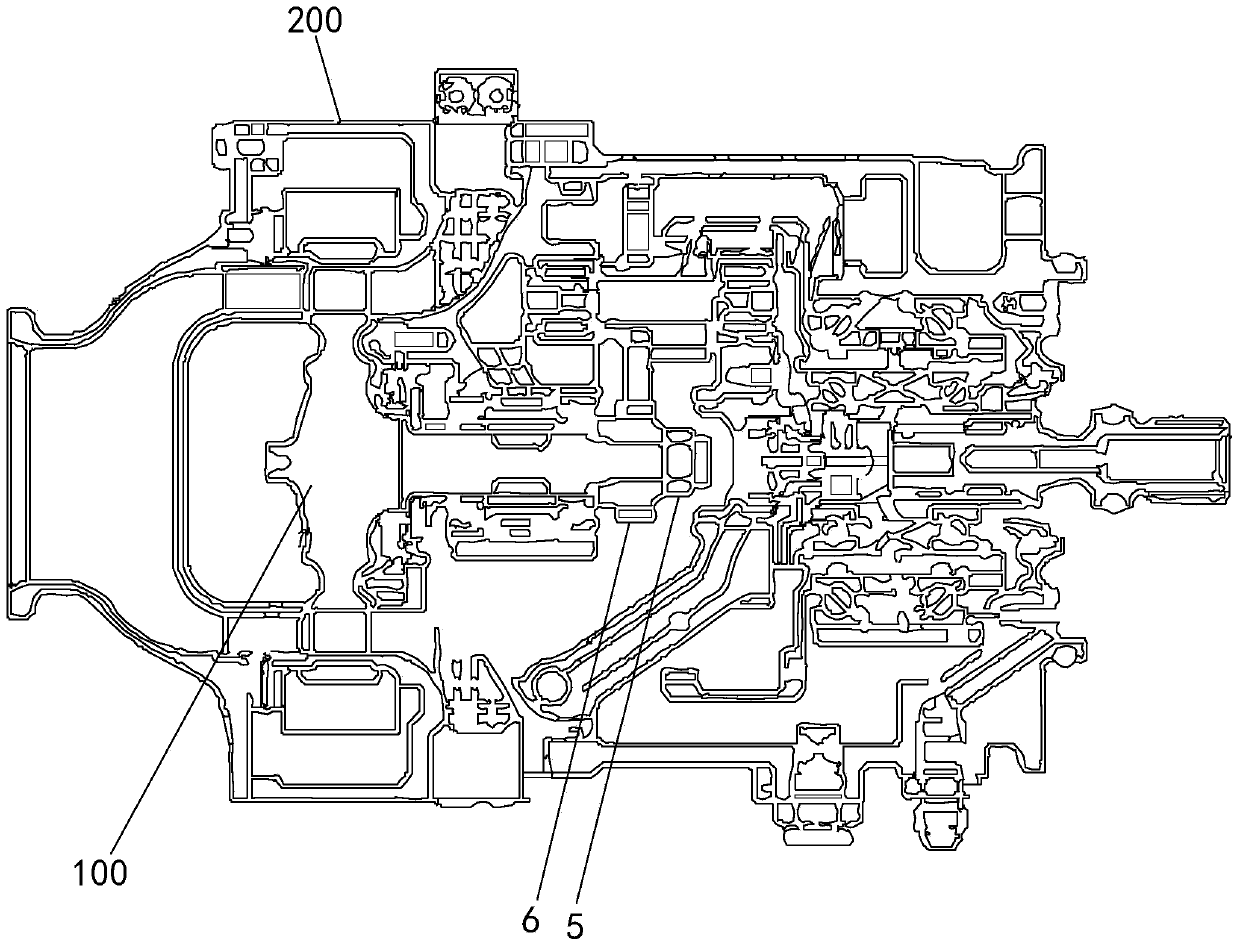

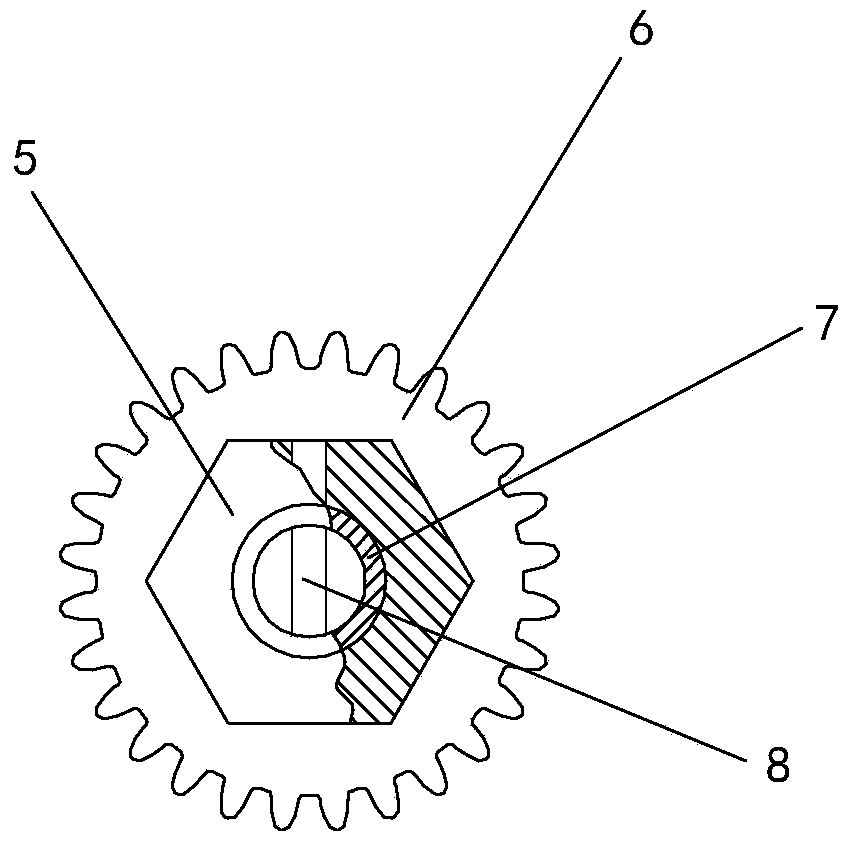

[0038] like Figure 4 to Figure 8 The shown clamping and positioning device for disassembling and assembling the rotor of an aircraft pneumatic starter includes a fixed support ring 1 and three sets of ratchet mounting and fixing components, and the three sets of ratchet mounting and fixing components are evenly inserted along the circumferential direction of the fixed support ring 1 On the fixed support ring 1, each group of pawl installation and fixing components is composed of a pawl installation support screw 2, a gear fixed pawl 3 and a rotating installation handle 4; the pawl installation support screw 2 is interspersed in the fixed support ring 1, and is threadedly connected with the fixed support ring 1, the angle between the adjacent ratchet mounting support screws 2 is 120°, the gear fixed ratchet 3 is a fan-shaped structure, and the gear fixed ratchet 3 is installed on the ratchet The installation support screw 2 is located at the inner rod end 21 in the fixed suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com