Novel auxiliary clamp for assembling spare wheel

A technology for assembling auxiliary and auxiliary fixtures, which can be used in manufacturing tools, workpiece clamping devices, etc., and can solve the problems of heavy spare tires, low production efficiency, and high labor intensity of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

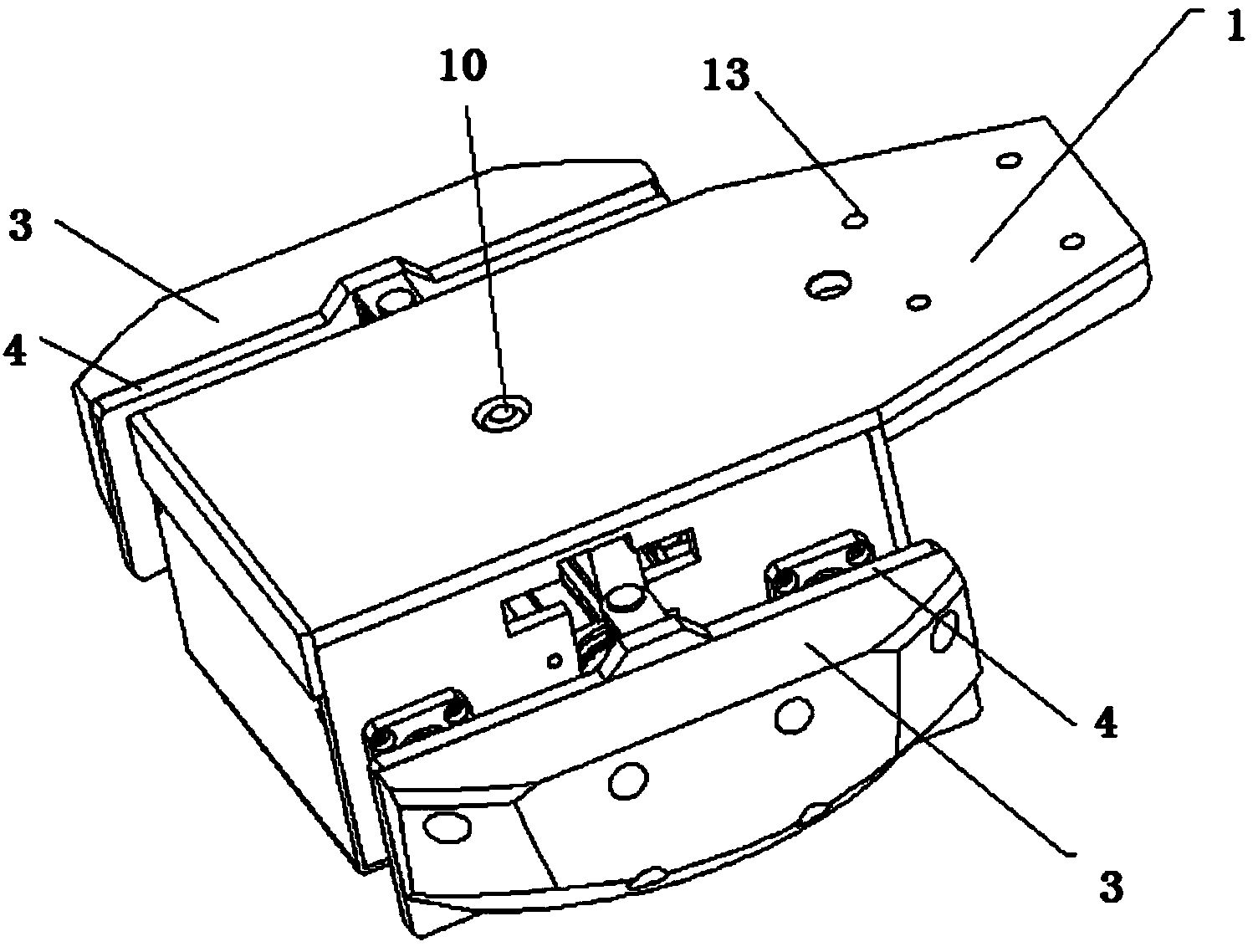

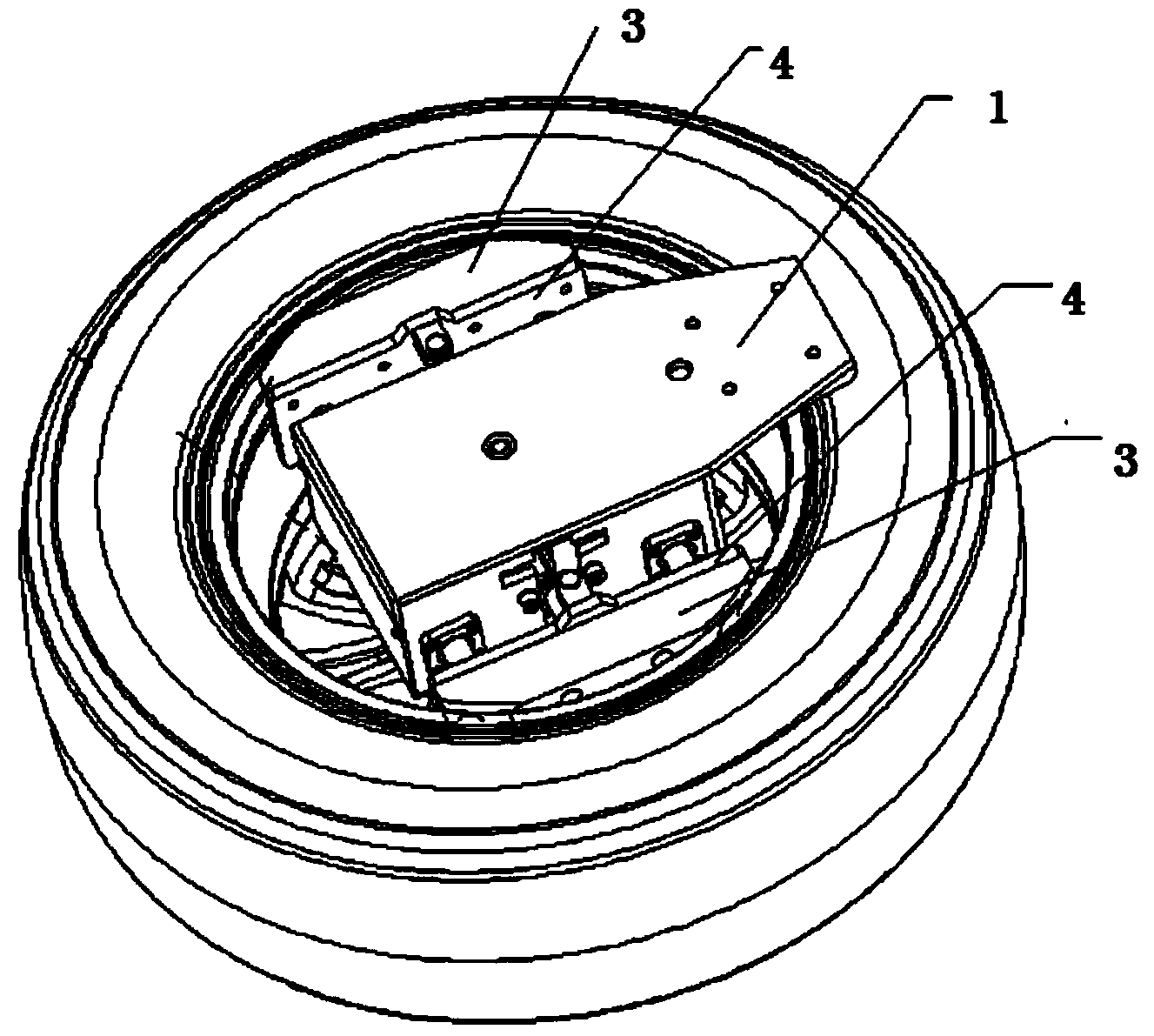

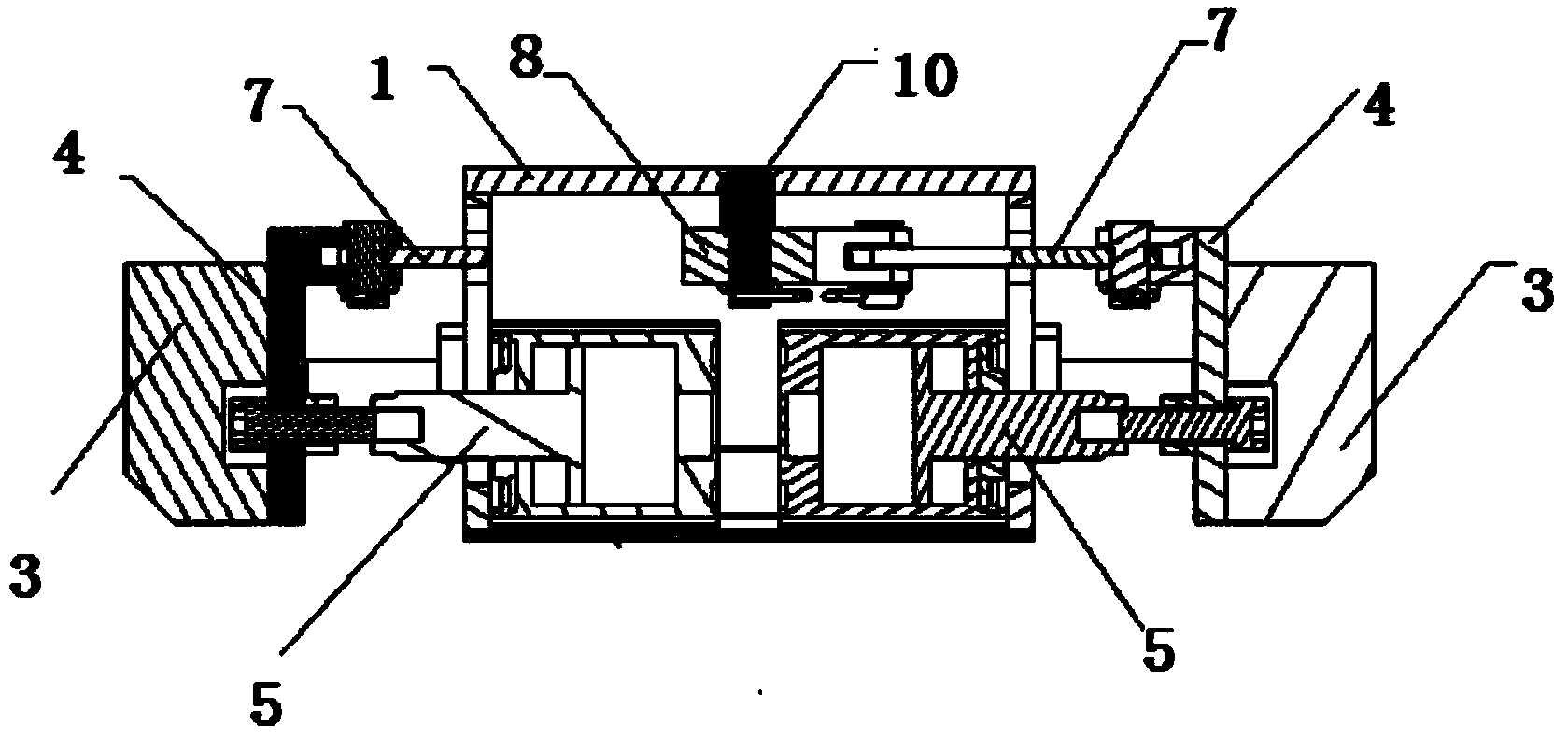

[0023] Such as Figures 1 to 5 As shown, the present invention provides a new spare tire assembly auxiliary clamp, which includes: a clamping block 3, the clamping block 3 moves in the radial direction in the hub of the spare tire to realize the alignment of the hub clamping and loosening; the cylinder 5, the cylinder 5 is connected with the clamping block 3, and drives the clamping block; the cylinder connection groove 1, the cylinder is fixed on the cylinder connection groove 1, and the The cylinder connecting groove has an outer connecting part 13 .

[0024] The clamp provided by the present invention uses the cooperation of the cylinder and the clamping block to prop up the wheel hub in the spare tire to realize the clamping of the entire spare tire. and so on to achieve an active connection. Pick-up and handling after clamping is complete.

[0025] Those skilled in the art can understand that the clamping of the hub by the clamping block 3 in the present invention is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com