Sterilizing tank of pasteurizing cooling machine

A technology of pasteurization and sterilizing tank, which is applied in food ingredients as antimicrobial preservation, food science, food preservation, etc. It can solve the problems of long heating and sterilization time and affecting the taste of food, so as to improve the effect, ensure food safety, The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

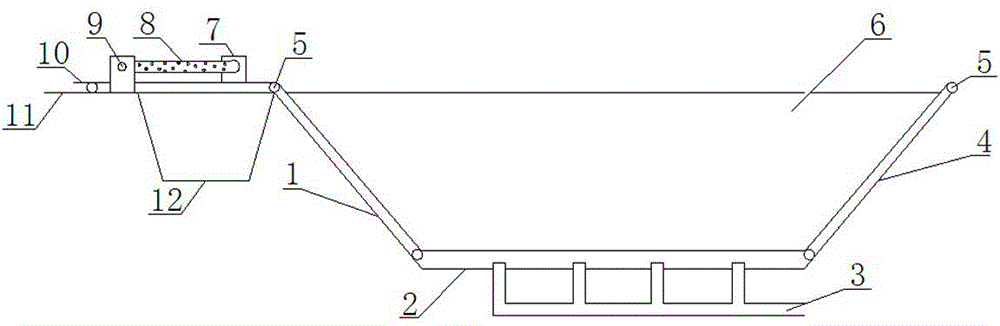

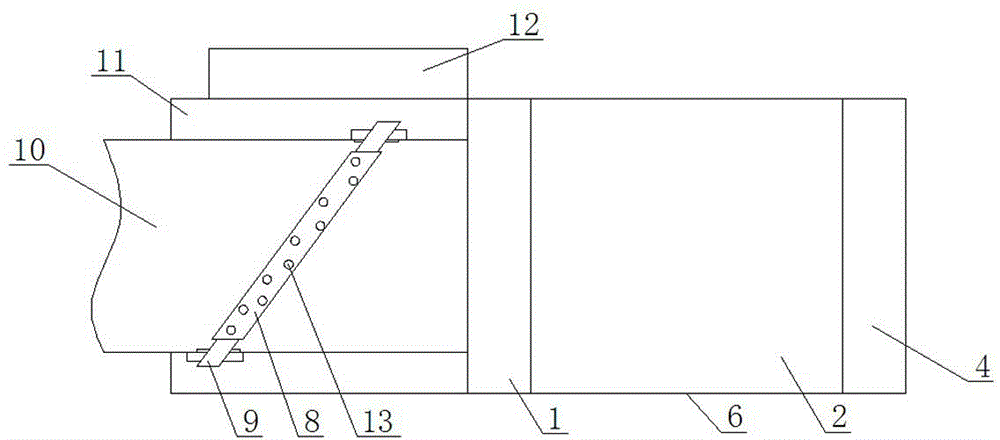

[0031] The sterilizing tank of the pasteurization cooling machine of the present embodiment comprises a bottom plate, two side plates and front and rear inclined plates, the bottom plate, two side plates, front inclined plates and rear inclined plates form a sterilizing tank, and the sterilizing tank is provided with a support The rollers of the conveyor belt; the bottom plate is connected with a steam spray pipe, the front inclined plate is connected with a horizontal support plate, the horizontal support plate is provided with rollers for supporting the conveyor belt, and the horizontal support plate is provided with a horizontal bar installed on the conveyor belt. On the top of the belt, the cross bar is installed on the frame through two support frames, and the two support frames are respectively installed on both sides of the conveyor belt. There is a collection bucket.

Embodiment 2

[0033] The sterilizing tank of the pasteurization cooling machine of the present embodiment comprises a bottom plate, two side plates and front and rear inclined plates, the bottom plate, two side plates, front inclined plates and rear inclined plates form a sterilizing tank, and the sterilizing tank is provided with a support The rollers of the conveyor belt; the bottom plate is connected with a steam spray pipe, the front inclined plate is connected with a horizontal support plate, the horizontal support plate is provided with rollers for supporting the conveyor belt, and the horizontal support plate is provided with a horizontal bar installed on the conveyor belt. On the top of the belt, the cross bar is installed on the frame through two support frames, and the two support frames are respectively installed on both sides of the conveyor belt; the cross bar is covered with rubber rollers, and rubber particles are arranged on the rubber rollers. A collecting bucket is arranged...

Embodiment 3

[0035] The sterilizing tank of the pasteurization cooling machine of the present embodiment comprises a bottom plate, two side plates and front and rear inclined plates, the bottom plate, two side plates, front inclined plates and rear inclined plates form a sterilizing tank, and the sterilizing tank is provided with a support The rollers of the conveyor belt; the bottom plate is connected with a steam spray pipe, the front inclined plate is connected with a horizontal support plate, the horizontal support plate is provided with rollers for supporting the conveyor belt, and the horizontal support plate is provided with a horizontal bar installed on the conveyor belt. On the top of the belt, the cross bar is installed on the frame through two support frames, and the two support frames are respectively installed on both sides of the conveyor belt; the cross bar is covered with a rubber roller, and a hemispherical rubber roller is provided on the rubber roller. particles. A colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com