Method for removing bitter taste of lemon juice with macroporous resin

A technology of lemon juice and macroporous resin, applied in application, food preparation, food science and other directions, can solve the problems of reducing product quality, increasing the pH of juice, unable to effectively use bitter substances, etc., achieving low processing cost and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for removing the bitterness of lemon juice with macroporous resin, the method may further comprise the steps:

[0025] 1) Select ripe, undamaged fresh lemon fruit, wash, peel, squeeze the juice, and filter to obtain lemon juice;

[0026] 2) Inactivate the lemon juice at 90°C for 10 minutes, then cool it down;

[0027] 3) The domestic LS-803C macroporous resin is soaked in absolute ethanol, pickled, and alkali washed to remove impurities, and then loaded into the column;

[0028] 4) At a room temperature of 20°C, pass the treated lemon juice through a LS-803C macroporous resin column with a height-to-diameter ratio of 10:1 at a flow rate of 2 BV / h to obtain debittered lemon juice.

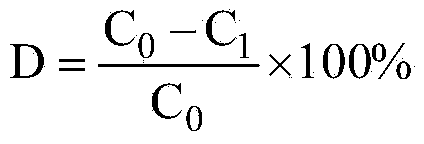

[0029] The content of bitter substances in lemon juice before and after passing through the column was measured, and the debittering rate was calculated; the debittering rates of naringin and limonin in lemon juice reached 92.40% and 60.53%, respectively.

Embodiment 2

[0031] A method for removing the bitterness of lemon juice with macroporous resin, the method may further comprise the steps:

[0032] 1) Select ripe, undamaged fresh lemon fruit, wash, peel, squeeze the juice, and filter to obtain lemon juice;

[0033] 2) Inactivate the lemon juice at 90°C for 10 minutes, then cool it down;

[0034] 3) The domestic LS-803C macroporous resin is soaked in absolute ethanol, pickled, and alkali washed to remove impurities, and then loaded into the column;

[0035] 4) At a room temperature of 20°C, pass the treated lemon juice through a LS-803C macroporous resin column with a height-to-diameter ratio of 10:1 at a flow rate of 5 BV / h to obtain debittered lemon juice.

[0036] The content of bitter substances in lemon juice before and after the column was measured, and the debittering rate was calculated; the debittering rates of the bitter substances naringin and limonin in lemon juice reached 90.99% and 58.36%, respectively.

Embodiment 3

[0038] A method for removing the bitterness of lemon juice with macroporous resin, the method may further comprise the steps:

[0039] 1) Select ripe, undamaged fresh lemon fruit, wash, peel, squeeze the juice, and filter to obtain lemon juice;

[0040] 2) Inactivate the lemon juice at 95°C for 8 minutes and cool it down;

[0041] 3) The domestic LS-803C macroporous resin is soaked in absolute ethanol, pickled, and alkali washed to remove impurities, and then loaded into the column;

[0042] 4) At a room temperature of 20°C, pass the treated lemon juice through a LS-803C macroporous resin column with a height-to-diameter ratio of 10:1 at a flow rate of 8 BV / h to obtain debittered lemon juice.

[0043] The content of bitter substances in lemon juice before and after passing through the column was measured, and the debittering rate was calculated; the debittering rates of the bitter substances naringin and limonin in lemon juice reached 80.72% and 54.92%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com