Composite mulberry leaf tea and preparation method thereof

A technology for mulberry leaf tea and tea base, applied in the field of compound mulberry leaf tea, can solve the problems of difficult to open the marketing situation, difficult to improve consumers with astringency and green taste, and heavy taste of green taste, so as to improve product market satisfaction, Improve food flavor, clear and bright tea soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation steps of black tea-lychee compound mulberry leaf tea are as follows:

[0040] (1) Black tea and lychee dried pulp are extracted, and 2% dextrin is added in the extract;

[0041] (2) Two kinds of extracts added with dextrin are compounded, and then the solid content (ie concentration) is adjusted to 10% to obtain the compounded liquid;

[0042] (3) measure dry weight (solid matter weight) and be the above-mentioned compound liquid of mulberry leaf tea tea base weight 10% for subsequent use;

[0043] (4) Evenly spray compound liquid on the mulberry leaf tea base, stir while spraying, and the single spraying weight is 20% of the tea base weight;

[0044] (5) Let the mulberry leaf tea base absorb the compound liquid naturally, so that the juice is evenly dispersed in the whole system, and the time is 30 minutes;

[0045] (6) The evenly absorbed mulberry leaf tea dregs are dried at 60°C until about 80% dry;

[0046] (7) Let cool and dry the mulberry leaf t...

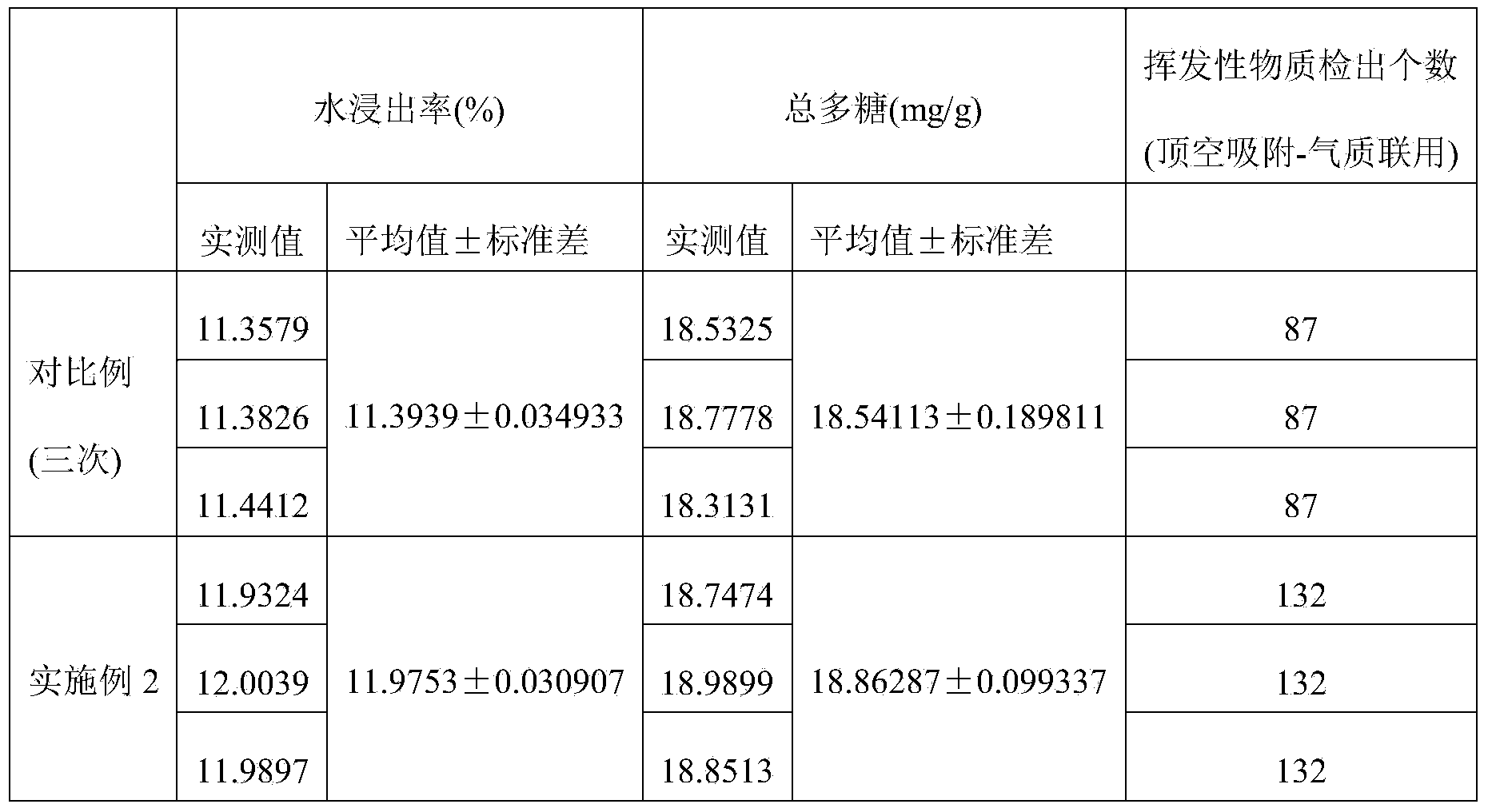

Embodiment 2

[0049] The preparation steps of ginseng-rosebud mulberry leaf tea are as follows:

[0050] (1) Ginseng and rose buds are extracted separately, 2% dextrin is added to the ginseng extract, and 4% dextrin is added to the rose bud extract;

[0051] (2) Two kinds of extracts that have added dextrin are compounded, and then the solid content is adjusted to 10% to obtain the compounded solution;

[0052] (3) measure dry weight and be the above-mentioned compound liquid of 5% of mulberry leaf tea base weight for subsequent use;

[0053] (4) Evenly spray the compound solution on the mulberry leaf tea base, and stir while spraying, and the single spraying weight is 15% of the tea base weight;

[0054] (5) Let the mulberry leaf tea base absorb the compound liquid naturally, so that the juice is evenly dispersed in the whole system, and the time is 30 minutes;

[0055] (6) Dry the evenly absorbed mulberry leaf tea dregs at 50°C until about 70% dry;

[0056] (7) Let cool and dry the mul...

Embodiment 3

[0059] Longan Mulberry Leaf Tea

[0060] (1) Squeeze fresh longan juice to eliminate enzymes, and add 1.5% vitamin C to the fresh juice;

[0061] (2) Regulate the longan juice solids content to about 15%;

[0062] (3) Measure the above-mentioned longan juice whose dry weight is 10% of the mulberry leaf tea base weight for subsequent use;

[0063] (4) Spray evenly on the mulberry leaf tea dhool, and turn it while spraying. The volume of a single spray should not exceed 10% of the volume of the tea dhool;

[0064] (5) Let the mulberry leaf tea base absorb the longan juice naturally, so that the juice is evenly dispersed in the whole system for 30 minutes;

[0065] (6) The evenly absorbed mulberry leaf tea dregs are dried at 50°C to 90% dry;

[0066] (7) Let cool and dry the mulberry leaf tea base, then repeat steps (4), (5), (6), until the longan juice measured in step (3) is sprayed and dried;

[0067] (8) Dry the dried mulberry leaf tea base at 90°C until fully dry, then spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com