Coconut cow milk beverage and preparation method thereof

A coconut milk and drink technology, applied in the field of coconut milk drink and its preparation, can solve the problems of weak flavor and single nutrition, achieve good taste, rich nutrition, and overcome the effect of large flavor differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

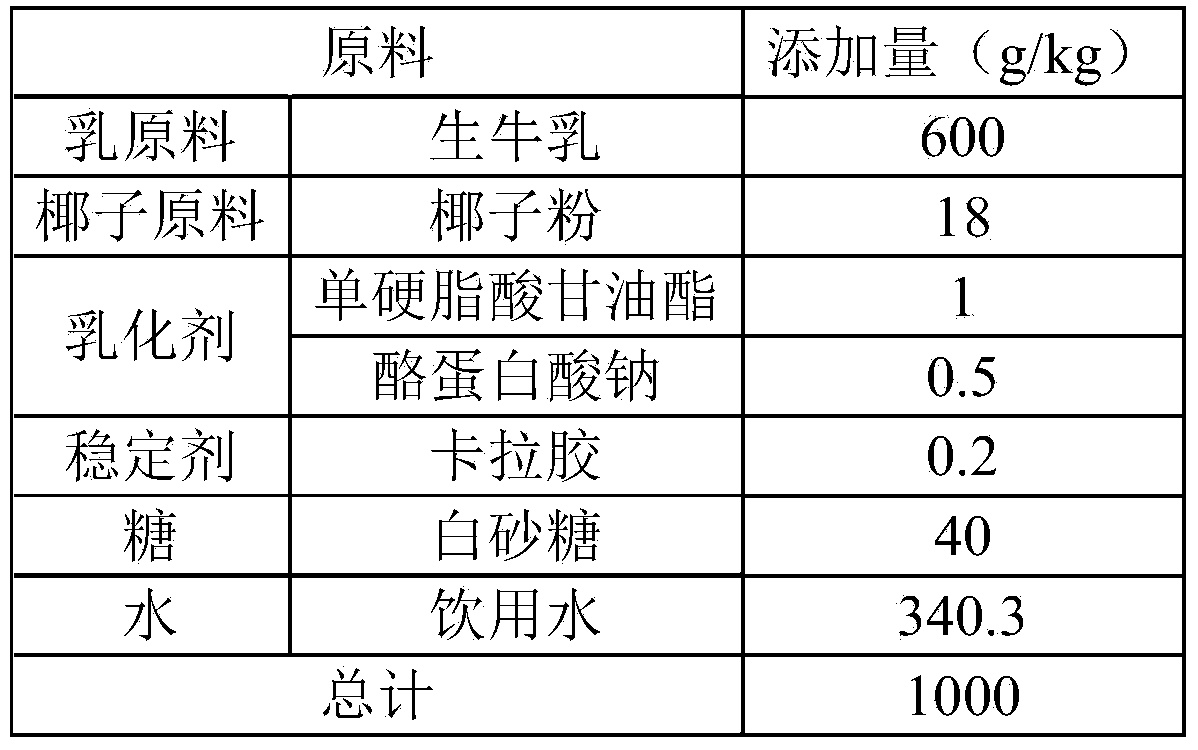

[0038] raw material:

[0039]

[0040] Preparation process steps and conditions:

[0041] (1) Ingredients: Add raw milk to part of the water, heat up to 70°C, add coconut raw materials, emulsifier, stabilizer and sugar, stir for 5 minutes, pass through a colloid mill, add the remaining water, and stir for another 3 minutes;

[0042] (2) Homogenization: Cool down to 60°C for homogenization, and the homogenization pressure is 200bar;

[0043] (3) Sterilization: heat preservation at 110°C for 10s;

[0044] (4) Filling: clean filling after cooling to 30°C;

[0045] (5) Fragrance aging: place it at 10°C for 3 days.

[0046] Product indicators:

[0047] project

Embodiment 2

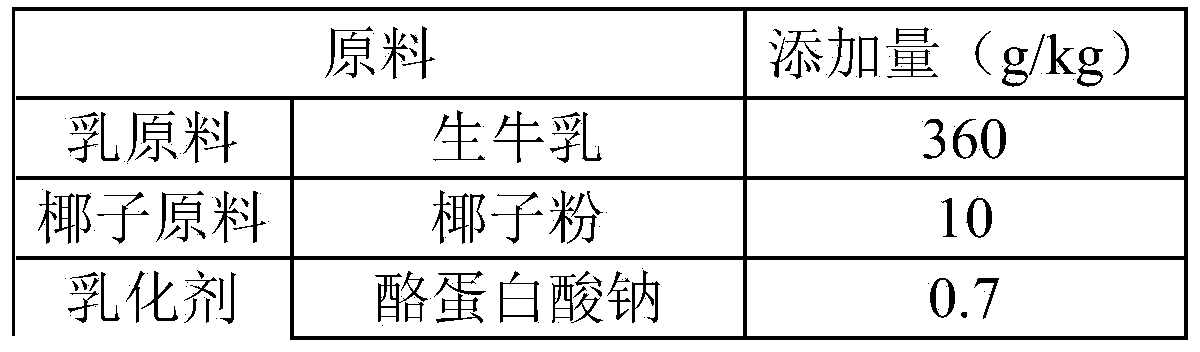

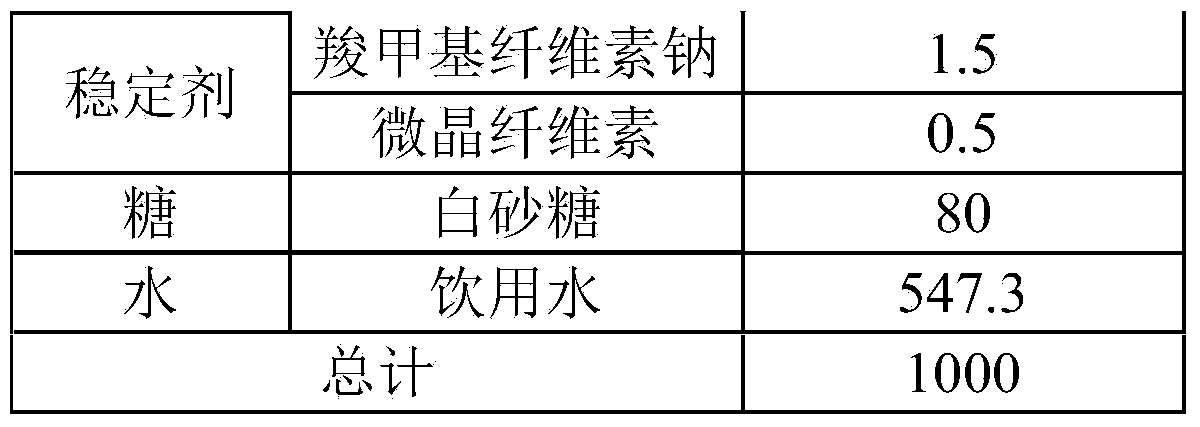

[0049] raw material:

[0050]

[0051]

[0052] Preparation process steps and conditions:

[0053] (1) Ingredients: Add raw milk to part of the water, heat up to 90°C, add coconut raw materials, emulsifier, stabilizer and sugar, stir for 10 minutes, pass through a colloid mill, add the remaining water, and stir for another 5 minutes;

[0054] (2) Homogenization: Cool down to 70°C for homogenization, and the homogenization pressure is 160bar;

[0055] (3) Sterilization: heat preservation at 90°C for 20s;

[0056] (4) Filling: clean filling after cooling to 10°C;

[0057] (5) Fragrance aging: place it at 8°C for 7 days.

[0058] Product indicators:

[0059] project

Embodiment 3

[0061] raw material:

[0062]

[0063] Preparation process steps and conditions:

[0064] (1) Ingredients: first heat 300g of water to 40°C, add whole milk powder, stir at this temperature for 40 minutes for hydration, continue to heat up to 80°C, add coconut raw materials, emulsifiers, stabilizers and sugar, stir for 8 minutes Pass through a colloid mill, add the remaining water, and stir for another 4 minutes;

[0065] (2) Homogenization: Cool down to 65°C for homogenization, and the homogenization pressure is 180bar;

[0066] (3) Sterilization: heat preservation at 120°C for 15s;

[0067] (4) Filling: aseptic filling after cooling to 20°C;

[0068] (5) Fragrance aging: place it at 9°C for 5 days.

[0069] Product indicators:

[0070] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com