Maillard flavor peptide with anti-oxidation function and preparation method thereof

A flavor peptide and anti-oxidation technology, which is applied in the field of Maillard flavor peptide and its preparation, can solve the problem of Maillard peptide anti-oxidation, deterioration of Maillard peptide flavor characteristics, and loss of flavor enhancement when reaction temperature rises and reaction time Function and other issues, to achieve the effect of excellent potato characteristic flavor, increase additional functions, and broaden the scope of research and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

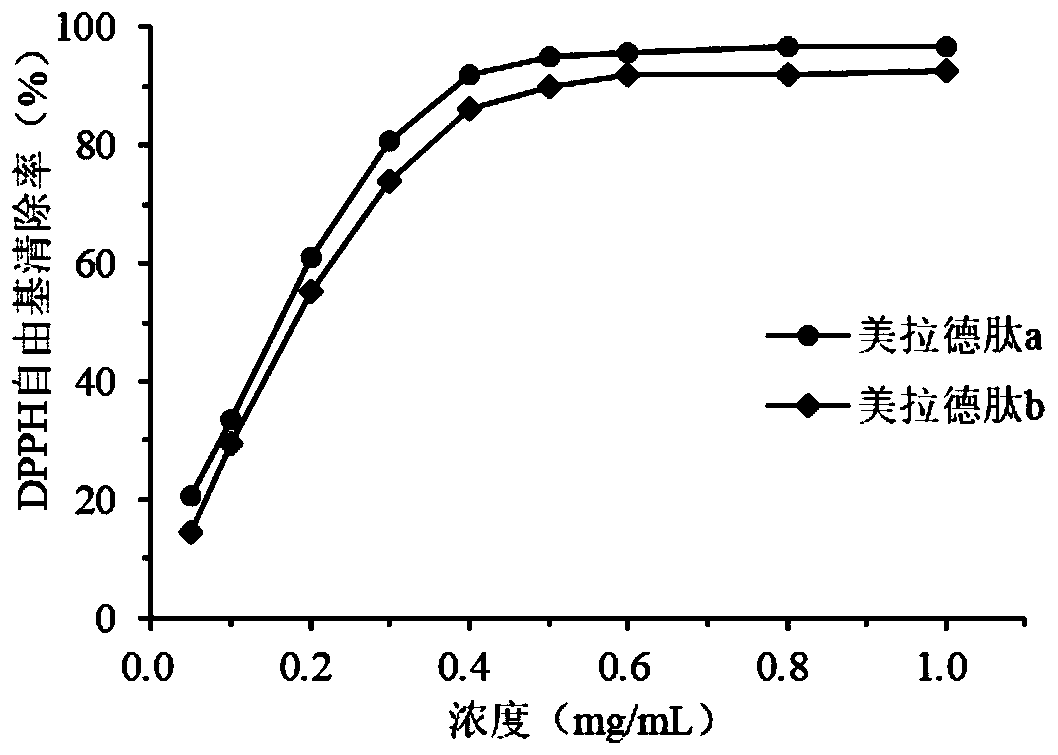

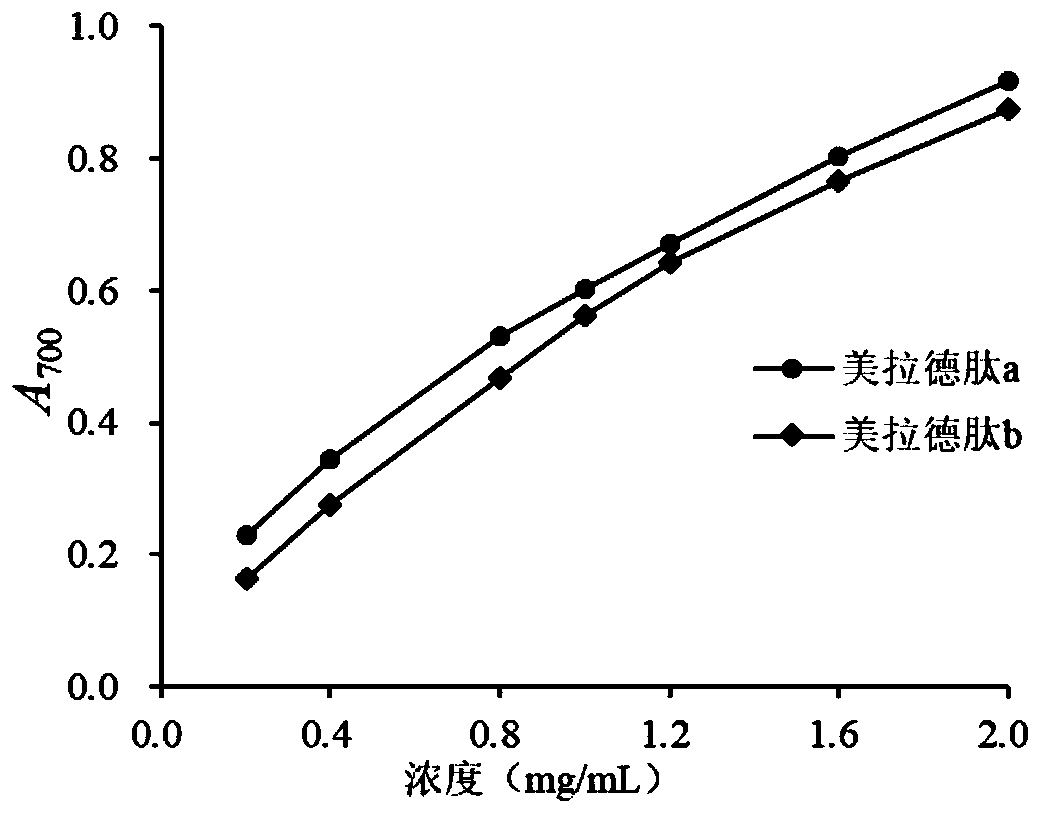

[0041]Weigh 30g of zein peptide with a mass concentration of 10%, add 0.27g and 0.03g of methionine and cysteine respectively (that is, the ratio of the two is 9:1), stir to dissolve it completely, and then add 0.45g of wood sugar. After quickly adjusting the pH to 7.4 with 6mol / L NaOH solution, transfer it to a Maillard reaction bottle with a magnetic stirring rotor, and tighten the bottle cap wrapped with a raw material tape, and place it in an oil bath at a predetermined temperature of 105°C. After reacting for 90 minutes, the reaction was rapidly cooled in an ice bath to terminate the reaction, and freeze-dried to obtain Maillard flavor peptide a.

[0042] Add the prepared Maillard flavor peptide and table salt into water, and the mass fraction of both is 25%, which is the Maillard flavor peptide product A.

Embodiment 2

[0044] Weigh 30g of zein peptide with a mass concentration of 10%, add 0.26g and 0.04g of methionine and cysteine respectively (that is, the ratio of the two is 6.5:1), stir to dissolve it completely, and then add 0.45g of wood sugar. After quickly adjusting the pH to 7.4 with 6mol / L NaOH solution, transfer it to a Maillard reaction bottle with a magnetic stirring rotor, and tighten the bottle cap wrapped with a raw material tape, and place it in an oil bath at a predetermined temperature of 105°C. After reacting for 90 minutes, the reaction was rapidly cooled in an ice bath to terminate the reaction, and freeze-dried to obtain Maillard flavor peptide b.

[0045] Add the prepared Maillard flavor peptide and table salt into water, and the mass fraction of both is 25%, which is the Maillard flavor peptide product B.

Embodiment 3

[0046] The application of embodiment 3 baked potato slices

[0047] Peel the potatoes and cut them into thin slices of about 3mm, soak them in water to remove the starch, take them out, wipe off the water on both sides with absorbent paper, brush the right amount of cooking oil on both sides, set the oven at 180°C, preheat for 10 minutes, and then Put the potato slices in the oven and bake for 15 minutes. After the baking is finished, the Maillard-flavored peptide products A and B prepared in Examples 1 and 2 are sprayed evenly on the surface of the potato chips in equal amounts immediately according to 0.5% of the mass of the baked potato chips. Descriptive sensory evaluation was performed after natural cooling.

[0048] The results showed that, compared with the blank control group without Maillard flavor peptide, the potato chips added with Maillard flavor peptide Product A had a more prominent roasted potato flavor, slightly meaty flavor, and a stronger roasted aroma. Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com