A method for optimizing power generation cost in iron and steel enterprises

A technology of power generation cost and enterprise, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as difficulty in ensuring safety and economy, large workload of dispatchers, and inability to effectively consider system safety in experience dispatching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

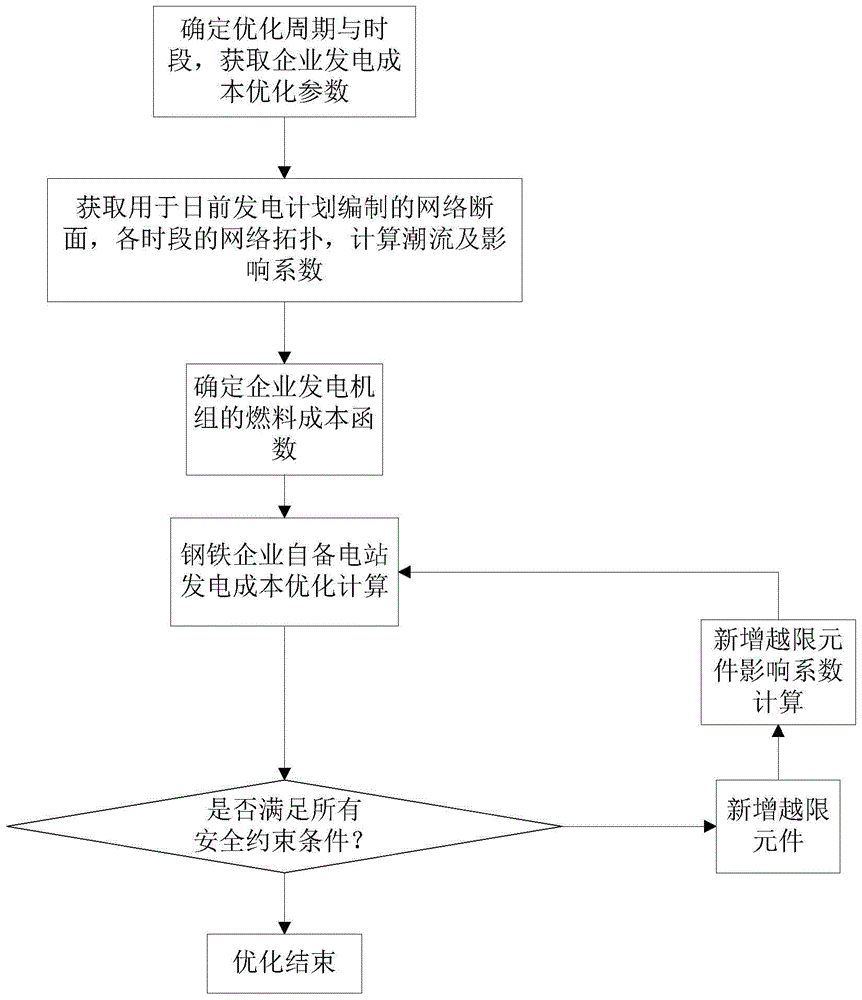

[0034] The present invention will be further described below in conjunction with accompanying drawing

[0035] see figure 1 , the method for optimizing the power generation cost of iron and steel enterprises in the present invention can meet the tasks of production load requirements, generator set output, line transmission capacity, etc., and at the same time ensure the safe and stable operation of the enterprise power grid, combined with load forecast curves, production and maintenance plans, further optimization and adjustment The output of self-generated power, as well as the proportional relationship between self-generated and purchased power, minimize the cost of power generation for enterprises. The method for optimizing the power generation cost of the iron and steel enterprise comprises the following steps:

[0036] The present invention comprises the following steps:

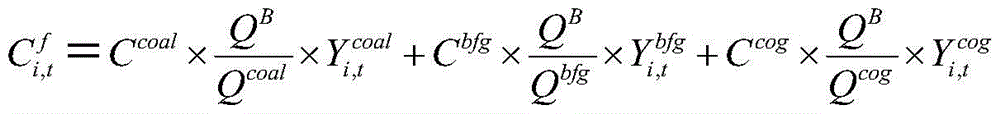

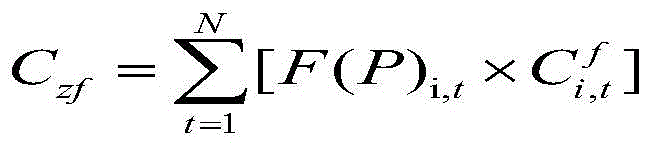

[0037] Step 1: Determine the scheduling period T that needs to be optimized for power generation cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com