Rapid self-correction indentation testing method of material testing machine

A material testing machine and fast technology, applied in the direction of testing material hardness, etc., can solve the problems of high frequency of indenter replacement, reduce the number of indenters used, high cost, etc., and achieve accurate indentation area, reduce use frequency, and calculate accurate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

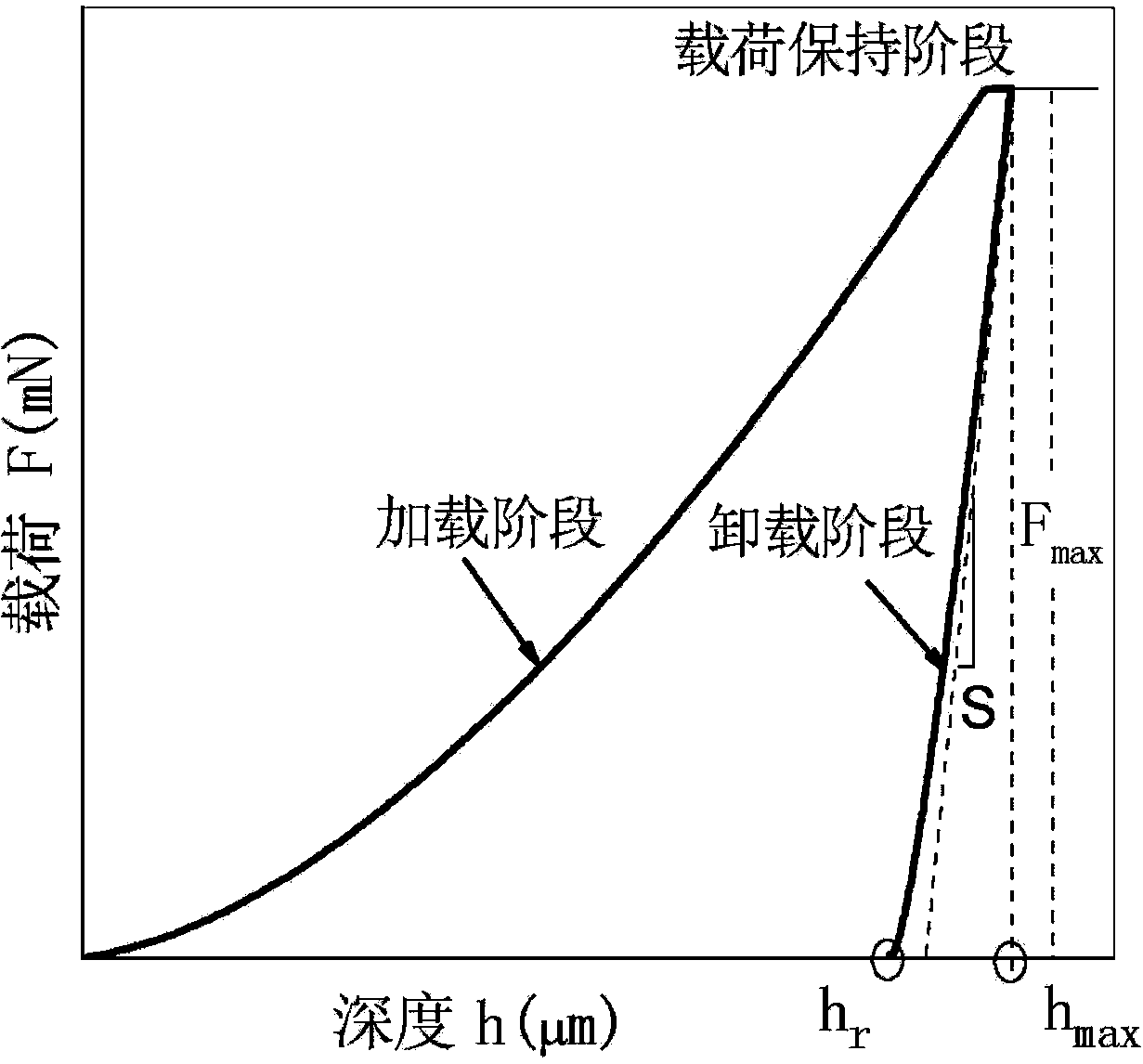

[0036] Such as figure 1 The load-depth curve of a typical single indentation test shown shows that an indentation test has gone through three stages: loading stage, load holding stage, and unloading stage. , unit μm), the ordinate represents the load F (unit: mN) acting on the indenter; the load holding stage in the figure is not necessary for the indentation test, but the ordinate value of the highest point of the loading stage curve is the maximum load f max ; h max is corresponding to F max The indentation depth, that is, the maximum indentation depth; h r is the residual indentation depth, and S is the contact stiffness. Using the following algorithm process for such a curve, we can distinguish the conventional calculation method to obtain the more accurate mechanical property parameters we need: yield strength or tensile strength.

[0037] (1) Calculate the integral value of the loading section: Wt; the integral value of the unloading section: We

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com