A method for non-destructive measurement of coating thickness by ultrasonic signal spectrum filtering technology

A filter technology and coating thickness technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve problems such as time domain aliasing and difficult identification of spectral resonance frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

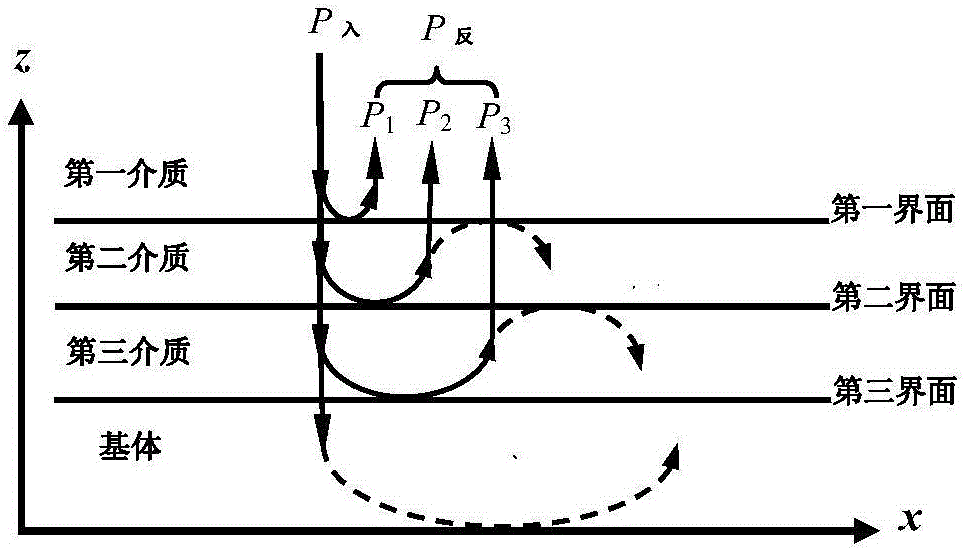

[0036] The method of non-destructive measurement of coating thickness by ultrasonic signal spectrum filtering technology adopts Figure 4 The one shown includes sample table 1, double-coated sample 2, first coating thickness 0.25mm, second coating thickness 0.45mm, 5MHz ultrasonic probe 3, USIP40 ultrasonic flaw detector 4, DPO4032 digital oscilloscope 5 And the ultrasonic echo thickness measuring system that computer 6 forms. The specific implementation process of the thickness measurement of the double-layer coating sample is as follows:

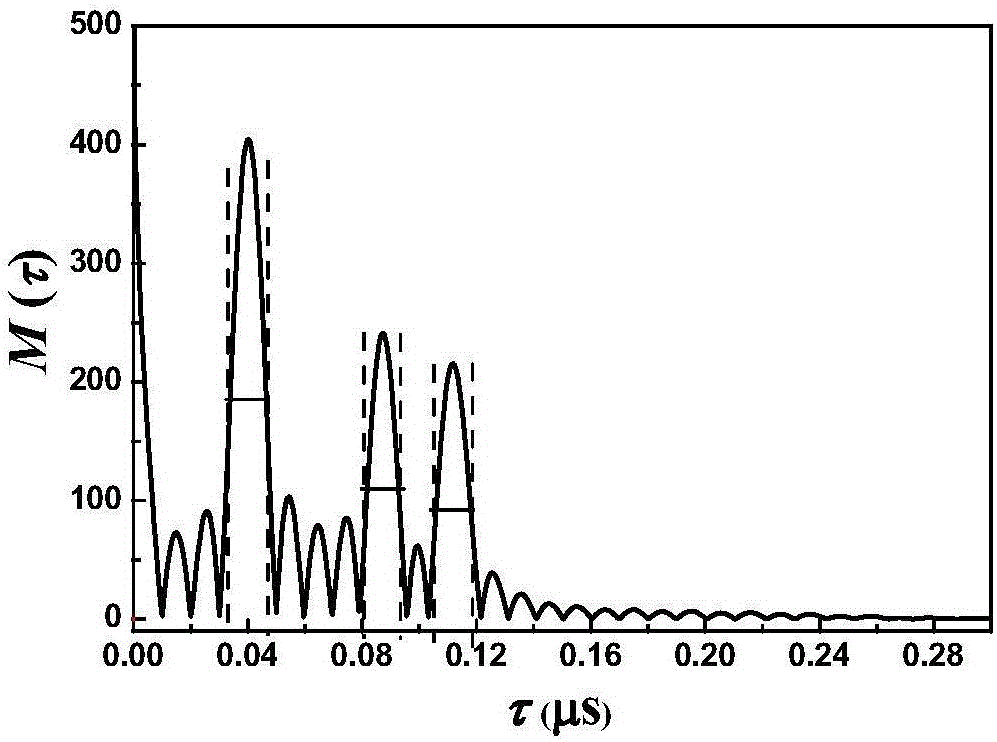

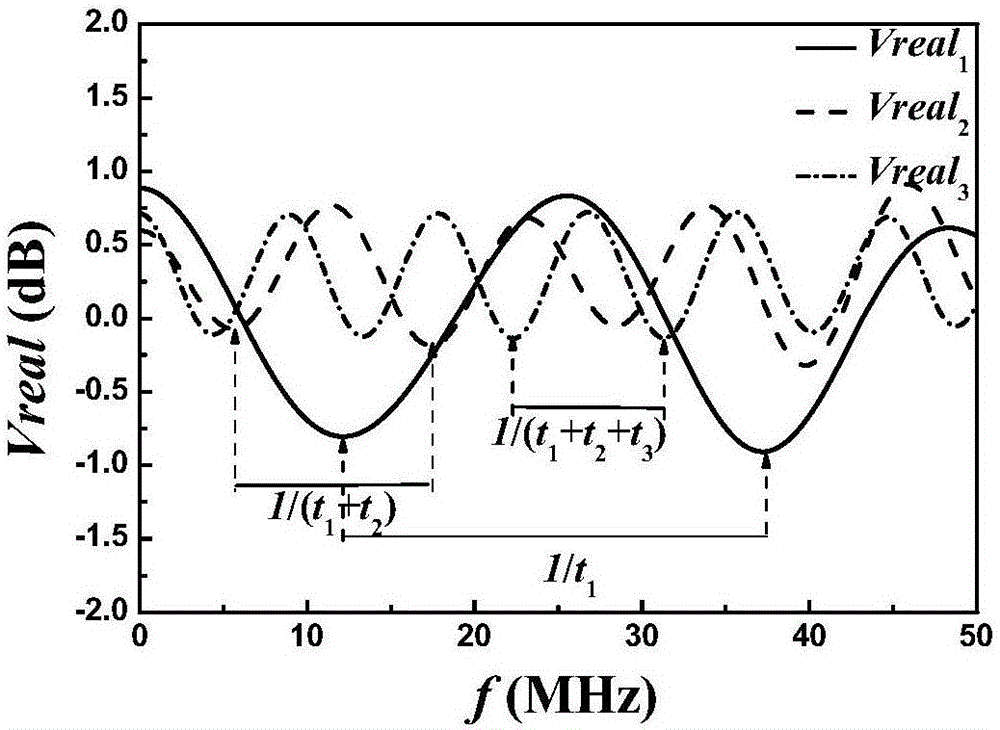

[0037] (1) For a double-coated sample with a coating thickness ranging from 0.2 to 0.8 mm, select an ultrasonic probe 3 with a nominal frequency of 5 MHz, and first connect the measuring device to the system and calibrate the instrument. Gather the reflected sound pressure P (x) of this ultrasonic probe by DPO4032 digital oscilloscope 5, see Figure 5 . The cycle T=0.20μs of the signal is read by the computer 6, and the -6dB effective f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com