Safe traction system of inclined-shaft concrete lining construction transportation trolley

A technology for transporting trolleys and concrete, which is applied in shaft lining, tunnel lining, shaft equipment, etc. It can solve the problem of low safety factor of trolley lifting and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0021] Example:

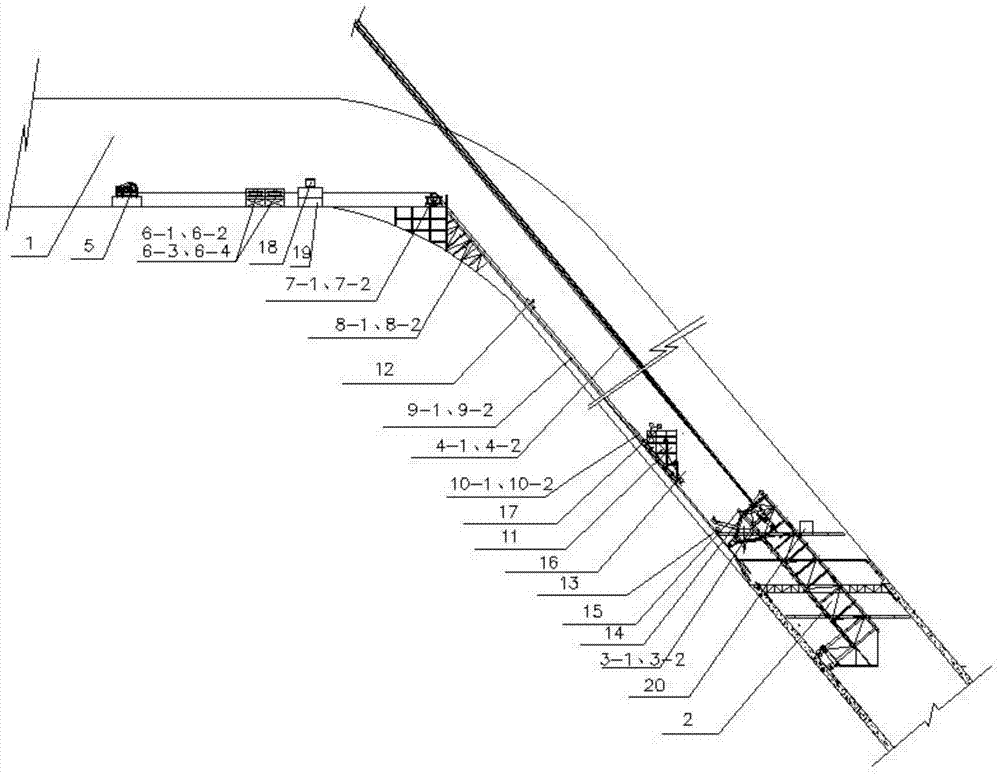

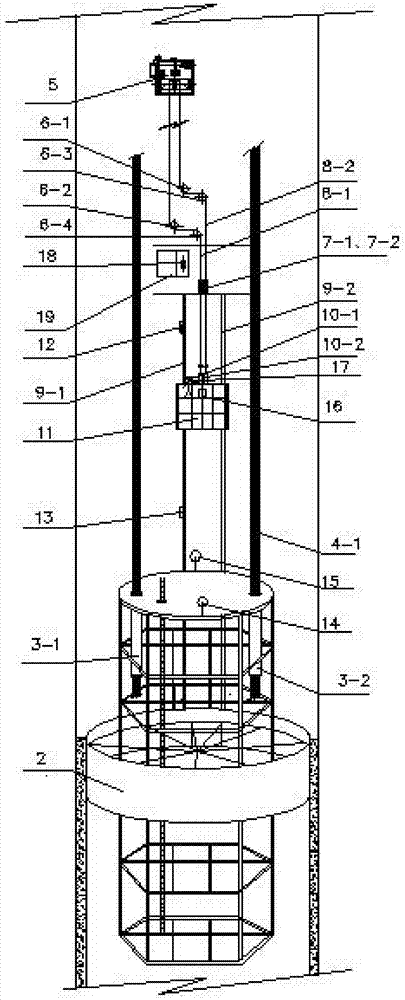

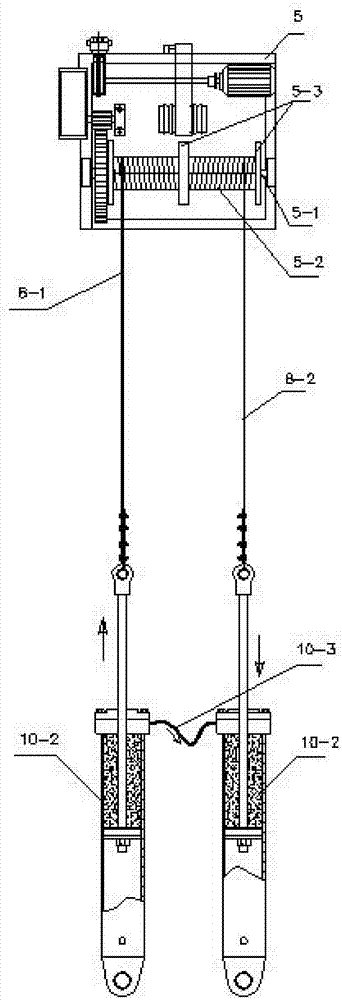

[0022] See figure 1 , figure 2 . In this example, the safety traction system of the transport trolley for the construction of the inclined shaft concrete lining, the length of the inclined shaft sometimes reaches 450 meters. See image 3 , a coaxial double-drum area winch 5 has a main shaft 5-1, the main shaft passes through the reel 5-2, and the middle and two ends of the reel respectively have partitions 5-3, and the reel is divided into two rope areas; The main shaft 5-1 is connected with a motor with a brake through a reducer, and the motor and the brake are electrically connected with the main control cabinet 19. Two traction wire ropes 8-1 and 8-2 are respectively drawn from the two rope areas for traction movement; the two traction wire ropes are respectively fixed on two traction trolleys 11 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com