Underground cutting mining method of process ore

A mining method and craft mine technology, applied in underground mining, surface mining, special mining, etc., can solve the problems of low craft value, high labor intensity, irregular shape of lump ore, etc., so as to improve resource craft value and reduce labor cost , the effect of high overall utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

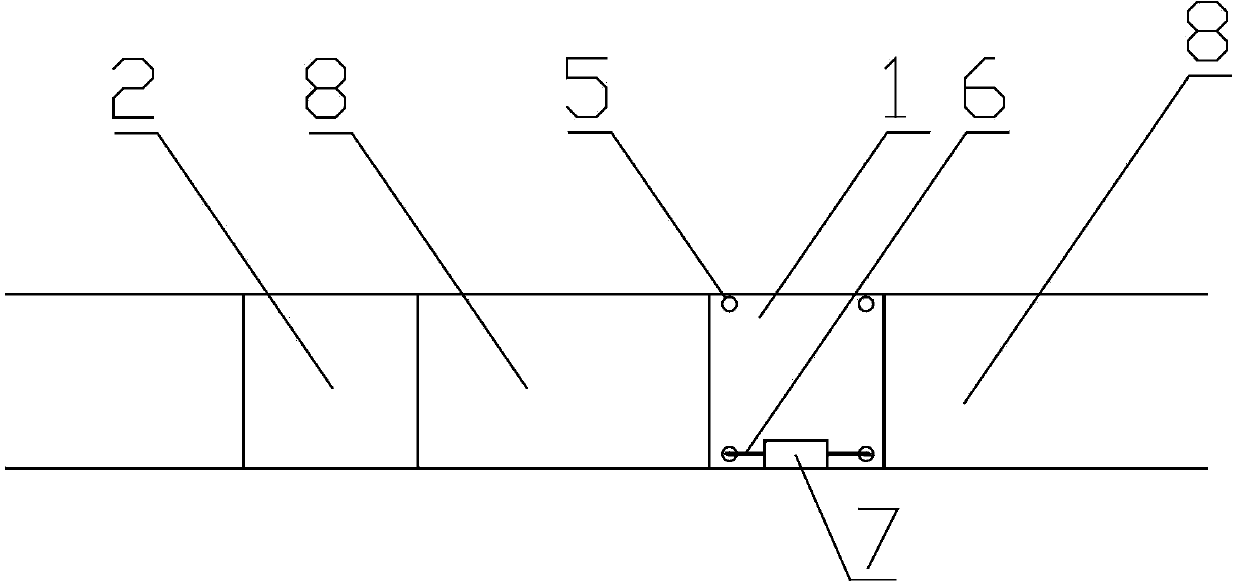

[0019] Embodiment of the present invention: a kind of mining method of thin ore body, as attached figure 1 and 2 As shown, the method specifically includes the following steps;

[0020] (1) First open a roadway 2 on the side of the ore body 1, and excavate horizontally from the roadway 2 to the ore body 1 to form a mine access road 3, which runs through the ore body 1, and makes the upper and lower sides of the ore body 1 There are two free surfaces 4 on the lower sides;

[0021] (2) Carry out drilling operations on one of the free surfaces 4, and drill holes at the four corners of the free surface 4, where the four corners refer to the upper left, lower left, upper right, and lower right corners of the free surface to get through Four bore holes 5 in the two free faces 4;

[0022] (3) Use a wire saw 6 to pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com