Pellet ore with good metallurgical property and proper alkalinity, and preparation method thereof

A technology of pelletizing and alkalinity, which is applied in the field of pelletizing and its preparation, can solve the problems of poor metallurgical properties of pelletizing, impeding the level of blast furnace smelting, and low alkalinity of pelletizing, and achieve suitable reducibility and good Promote the application value and optimize the effect of charge structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

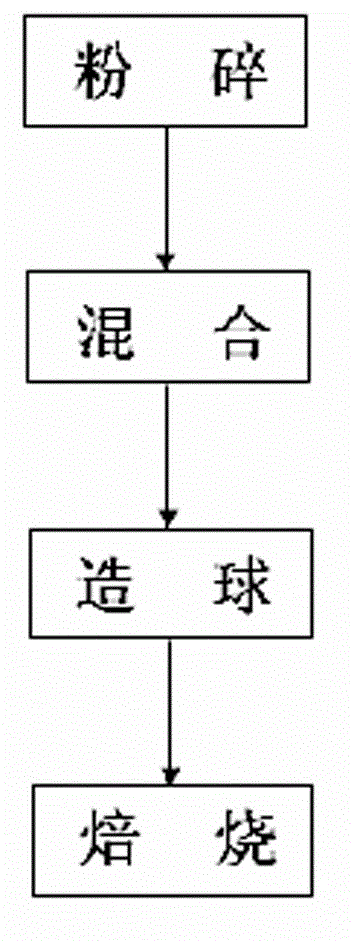

[0021] A method for preparing pellets with good smelting properties and suitable alkalinity, which is characterized in that it includes the steps of pulverizing, mixing, pelletizing and roasting, and specifically includes:

[0022] A. Crushing: crush limestone or dolomite to a particle size of 10~15mm, and then crush it into a powder with a particle size of ≤0.074mm;

[0023] B. Mixing: add limestone powder or dolomite powder to the iron concentrate powder in an amount of 2.8~5.3%, and mix evenly to obtain a mixed mineral material;

[0024] C. Pelletizing: adjust the water content of the mixed mineral material to 8~9%, and pelletize in the disc pelletizer to obtain raw pellets;

[0025] D: Roasting: In the roaster, first dry and preheat the raw pellets at 200~960°C for 12~17min, then roast at 1250~1280°C for 25~30min, and then cool to room temperature to obtain the finished pellets .

[0026] In the steps A and B, the content of calcium oxide (CaO) in the limestone powder is...

Embodiment 1

[0038] A. Pulverization: crush limestone with a calcium oxide content of 53.7% with a PE150×250 jaw crusher to a particle size of 10-15mm, and then use a YGM9517 Raymond mill to crush it into a powder with a particle size of ≤0.074mm. The content of fine particles with a particle size of <0.074mm in the powder reaches 90%.

[0039] B. Mixing: Add limestone powder to iron concentrate powder in an amount of 2.8%. The iron concentrate powder contains 92% fine particles with a particle size of <0.074mm. Mix the two evenly to obtain a mixed mineral material.

[0040] C. Pelletizing: Adjust the moisture content of the mixed mineral material to 8%, and perform pelletizing in a Ф6000×600 disc pelletizing machine. The speed of the disc pelletizing machine is set to 7r / min, and the inclination angle is 47°. , get raw balls.

[0041] D: Roasting: In a Ф5000×33000 type grate machine——rotary kiln, first dry and preheat the raw balls at 350~950°C for 14 minutes, then roast at 1260°C for 28...

Embodiment 2

[0044] A. Pulverization: crush limestone with a calcium oxide content of 53.7% with a PE150×250 jaw crusher to a particle size of 10-15mm, and then use a YGM9517 Raymond mill to crush it into a powder with a particle size of ≤0.074mm. The content of fine particles with a particle size of <0.074mm in the powder reaches 92%.

[0045] B. Mixing: Add limestone powder to iron concentrate powder in an amount of 3.5%. The iron concentrate powder contains 93% fine particles with a particle size of <0.074mm. Mix the two evenly to obtain a mixed mineral material.

[0046] C. Pelletizing: Adjust the moisture content of the mixed mineral material to 9%, and perform pelletizing in a Ф6000×600 disc pelletizer. The speed of the disc pelletizer is set to 8r / min, and the inclination angle is 46°. , get raw balls.

[0047] D: Roasting: In a Ф5000×33000 type grate machine——rotary kiln, first dry and preheat the green balls at 350~950°C for 13 minutes, then roast at 1270°C for 26 minutes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com