Wet Wipe Packaging System

A packaging system and technology of wet wipes, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inconvenient transportation or carrying of wet wipes bags, inability to remove air from wet wipes bags, and residual air in wet wipes bags, etc. Achieve the effects of easy transportation and portability, compact structure, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

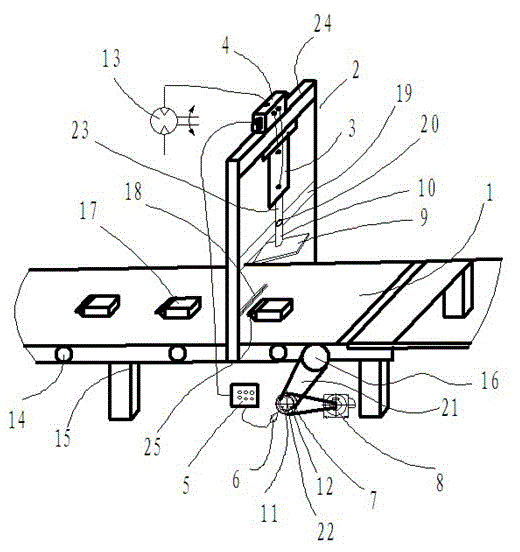

[0015] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a wet tissue packaging system includes a frame 15, which is provided with a wet tissue conveying device, a heat sealing device 18, and an exhaust control device. The exhaust control device is located on the right side of the heat sealing device 18, and the frame 15 The lower part is equipped with a frequency conversion motor 8, the power output shaft of the frequency conversion motor 8 is connected with the intermediate transmission shaft 7 through a belt, and the intermediate transmission shaft 7 is provided with an intermediate transmission wheel. The wheel is connected to the conveying driving wheel 16 through a belt 21, and the wet wipes conveyor belt 1 is connected to the frame 15 through the support wheel 14. The exhaust control device includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com